Preparation method of tetramethyl bisphenol F epoxy resin

A technology of tetramethyl bisphenol and epoxy resin, applied in the field of epoxy resin, can solve the problems of high melting point and increased filling amount of filler, and achieve the effects of simple operation, increased production profit and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

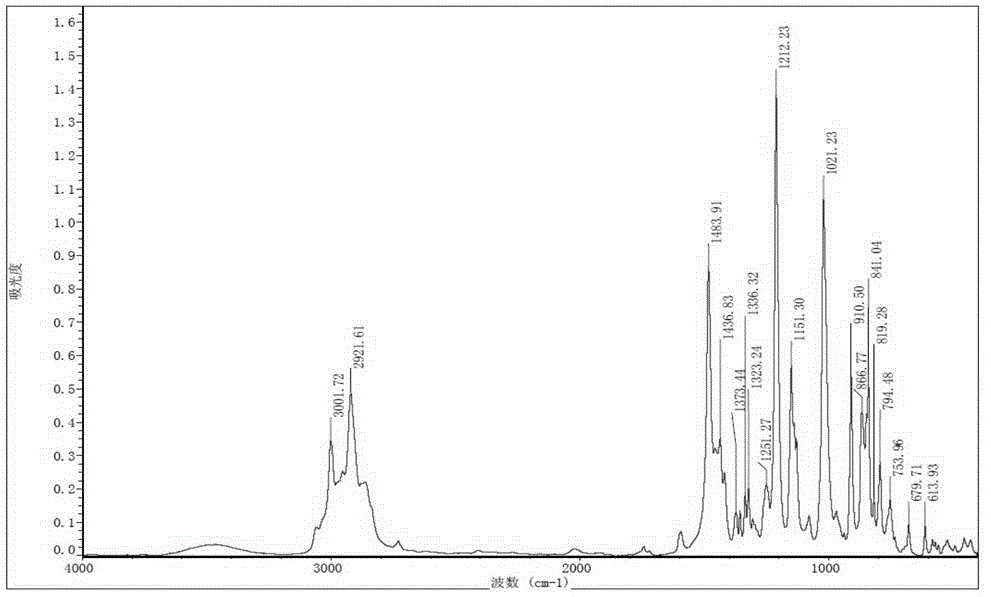

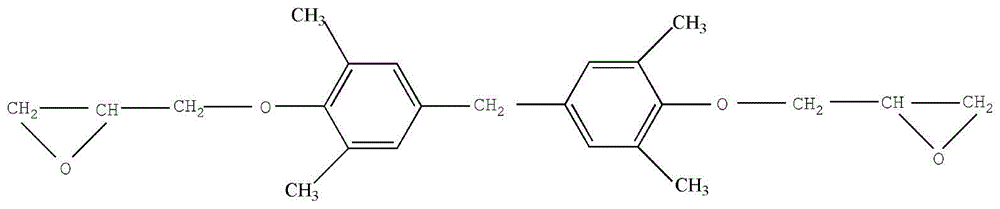

Embodiment 1

[0023] Add 140g of 4,4'-methylenebis(2,6-dimethyl)phenol, 690g of epichlorohydrin, and 2g of glycerol into a four-necked flask with stirring and a thermometer. Under the protection of nitrogen, , heat and stir to dissolve, add 25g of sodium bicarbonate solution with a mass fraction of 20%, and react at 60°C for 4 hours, then add 98g of 50% sodium hydroxide solution under a vacuum of 0.06MPa to catalyze the ring-closing reaction, react for 6h, and depressurize Recovery of epichlorohydrin. Then add 140g of toluene and 140g of cyclohexanone, add 8g of 50% sodium hydroxide solution for refining, react at 85°C for 3h, wash with water until neutral, and remove the solvent under reduced pressure to obtain tetramethylbisphenol F epoxy resin. Test results: melting point: 72°C, viscosity: 0.11p (150°C), epoxy equivalent: 195g / eq.

Embodiment 2

[0025] Add 140g of 4,4'-methylenebis(2,6-dimethyl)phenol, 750g of epichlorohydrin, and 8g of 1,4-dioxane into a four-neck flask with stirring and a thermometer. Under the protection of high-purity nitrogen, heat and stir to dissolve, add 50g of potassium hydroxide solution with a mass fraction of 10%, react at 40°C for 4 hours, add 110g of 50% potassium bicarbonate solution under vacuum of 0.07MPa to catalyze the ring-closing reaction, After 5 hours of reaction, epichlorohydrin was recovered under reduced pressure. Then add 258g of methyl isobutyl ketone, add 10g of sodium carbonate solution with a mass fraction of 50% to refine, react at 85°C for 3h, wash with water until neutral, and remove the solvent under reduced pressure to obtain tetramethylbisphenol F epoxy resin. Test results: melting point: 69°C, viscosity: 0.08p (150°C), epoxy equivalent: 193.5g / eq.

Embodiment 3

[0027] Add 140g of 4,4'-methylenebis(2,6-dimethyl)phenol, 520g of epichlorohydrin in a four-neck flask with stirring and a thermometer, add ethylene glycol dimethyl ether 4g, and Under the protection of pure nitrogen, heat and stir to dissolve, add 100g of sodium hydroxide solution with a mass fraction of 5%, and react at 60°C for 4 hours, then add 150g of 40% sodium hydroxide solution under a vacuum of 0.04MPa to catalyze the ring-closing reaction. After 5 hours of reaction, epichlorohydrin was recovered under reduced pressure. Then add 320g of cyclohexanone, add 10g of sodium bicarbonate solution with a mass fraction of 50% to refine, react at 60°C for 3h, wash with water until neutral, and remove the solvent under reduced pressure to obtain tetramethylbisphenol F epoxy resin. Test results: melting point: 69°C, viscosity: 0.08p (150°C), epoxy equivalent: 196.2g / eq.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com