Rare-earth element-containing up-conversion luminescent temperature sensitive material as well as preparation method and application thereof

A technology of rare earth elements and sensitive materials, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of limited application and low luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

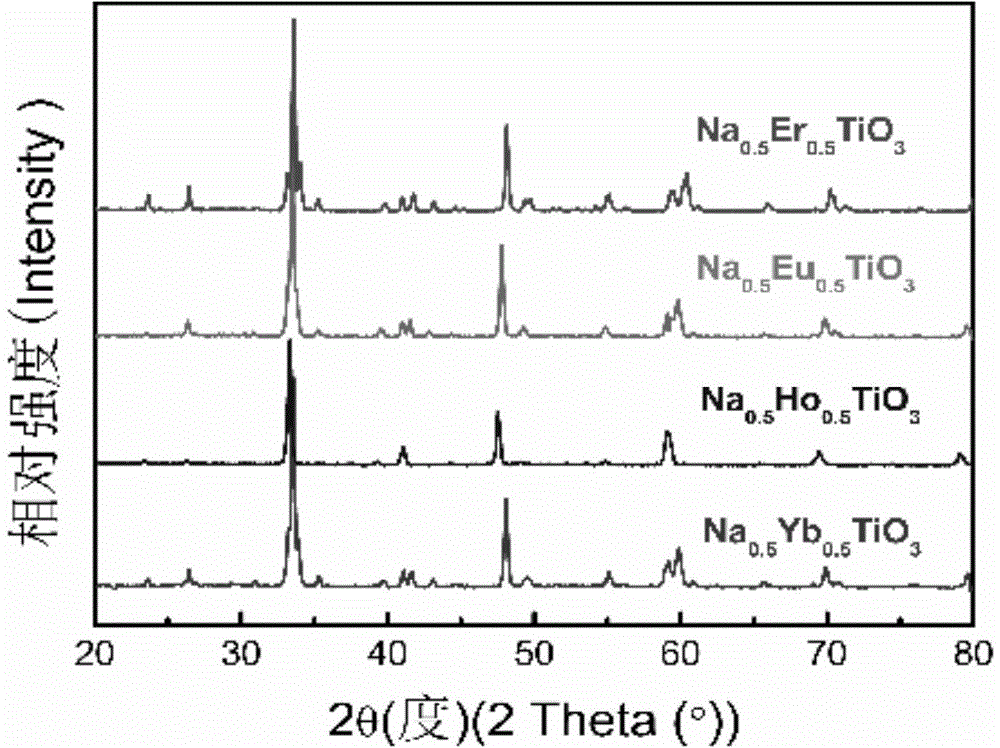

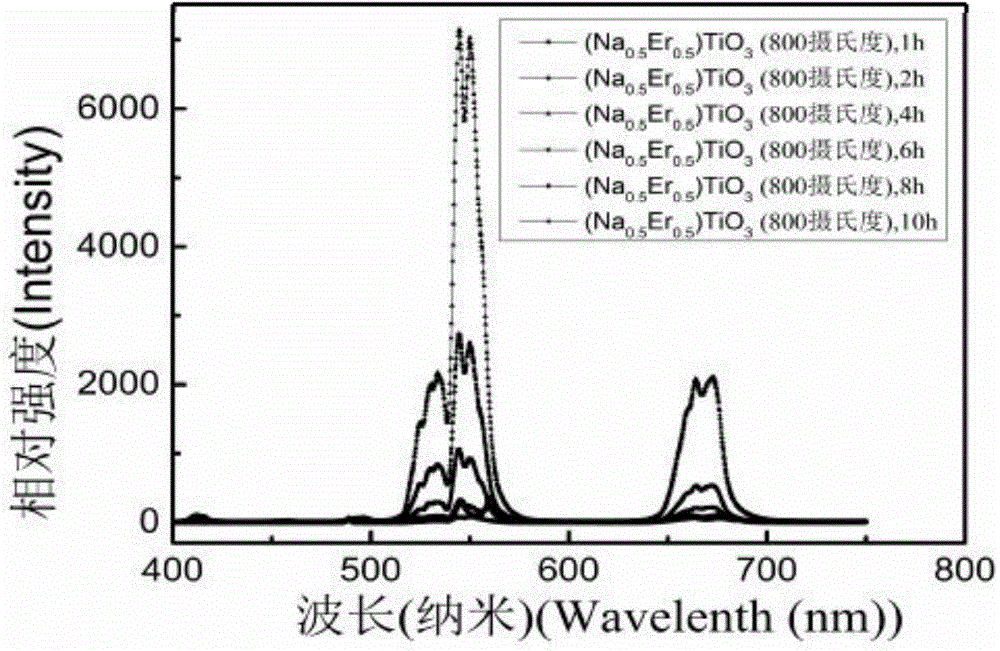

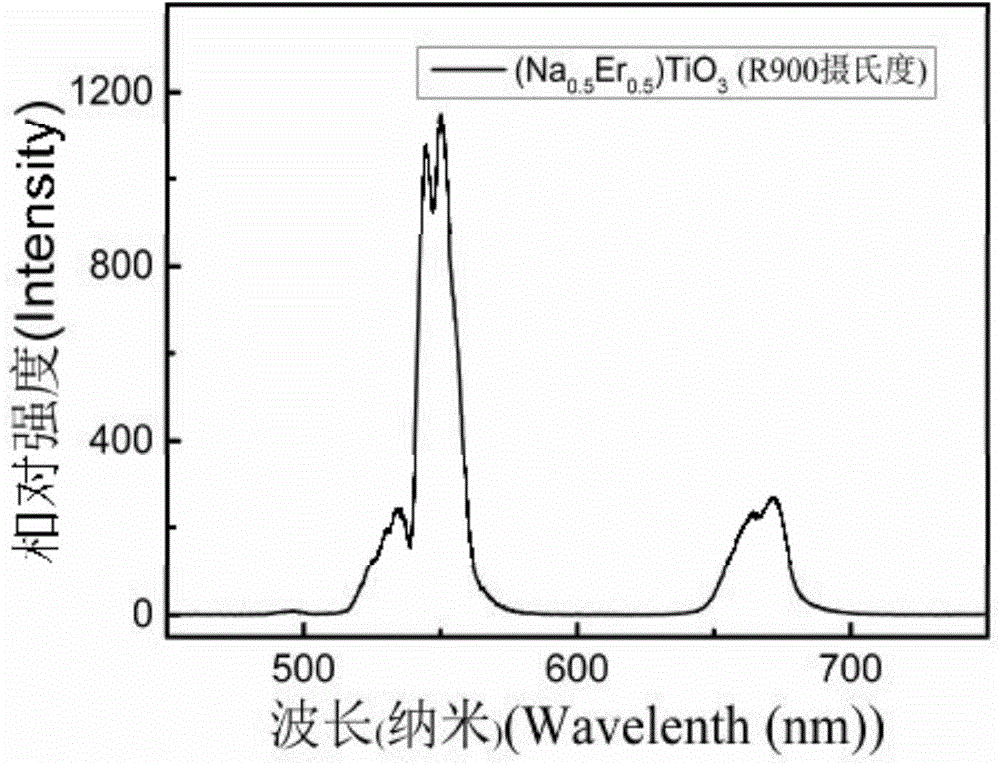

[0067] prepared by high energy ball milling (Na 0.5 Er 0.5 )TiO 3 Powder material, the preparation method is as follows:

[0068] Using high-purity sodium carbonate (99.8%), erbium oxide powder (99.9%), and titanium dioxide powder (99.9%) as raw materials, weigh the raw materials according to the stoichiometric ratio, put the weighed raw materials into a special ball mill tank, and then A certain amount of stearic acid is added thereto, and a small amount of n-amyl alcohol is added simultaneously. Finally, the PULVERISETTE 5 high-energy ball mill was used for high-speed ball milling for 4 hours, the speed was set at 350 rpm, and the ball milling was performed in forward and reverse mode. The milling time and intermittent interval were 20 minutes and 20 minutes, respectively. Then dilute the mixed material after ball milling with absolute ethanol, remove stearic acid after standing still, and then use a centrifuge to separate it, take out the pretreated powder, then heat tre...

Embodiment 2

[0070] Prepared by molten salt method (Na 0.5 Er 0.5 )TiO 3 Powder material, the preparation method is as follows:

[0071] According to the general chemical formula (Na 0.5 Er 0.5 )TiO 3 , the initial raw materials are high-purity sodium chloride (NaCl, 98%), erbium oxide powder (Er 2 o 3 , 99.9%), titanium dioxide powder (TiO 2 , 99.9%); and weigh each initial raw material according to its stoichiometric ratio, and add lithium chloride to it as a molten salt (the mass ratio of initial raw material to LiCl is 1:1.2), and put the mixed raw material in an agate mortar Grind for 3 hours to make it evenly mixed to make a precursor powder for molten salt reaction. Then transfer the precursor powder to a corundum crucible with a cover, and finally heat-treat at 750°C for 10 hours. After cooling in the furnace, soak it in deionized warm water (water temperature 80°C) for 36 hours to make it soft (you can add deionized water to prevent it from drying out). Then change t...

Embodiment 3

[0073] prepared by solvothermal method (Na 0.5 Er 0.5 )TiO 3 Powder material, the preparation method is as follows:

[0074] According to the chemical formula (Na 0.5 Er 0.5 )TiO 3 , where the initial raw materials are high-purity potassium hydroxide (NaOH, 99%), erbium nitrate [Er(NO 3 ) 3 ·5H 2 O, 99.9%], titanium tetra-n-butoxide (tetrabutyl titanate) liquid (C 16 h 36 o 4 Ti, 98%); each initial raw material was weighed according to its stoichiometric ratio. The solvent is deionized water, absolute ethanol, and ethylene glycol; after mixing the raw materials, add them to deethylene glycol and fully stir to dissolve them completely. Then add an appropriate amount of NaOH to the mixed solution and make it fully dissolved. Finally, the mixed solution is transferred to a hydrothermal kettle for solvothermal reaction, the reaction temperature is 180°C, and the reaction time is 24 hours; after the solvent heat treatment, the upper layer solution is poured out, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com