Magnetic iron oxide-immobilized ionic liquid solid acid material catalyst and preparation method thereof

A technology of magnetic iron oxide and ionic liquids, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve problems such as unrecoverable and difficult stratification, and achieve Ease of recovery, mild reaction, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Magnetic Iron Oxide Immobilized Vinylimidazolium Sulfate Ionic Liquid Solid Acid Materials

[0032] Preparation of step 1 ylide

[0033] Weigh the raw materials of vinylimidazole and 1,4-butane sultone in equal quantities, and stir at room temperature for 72 hours to obtain a white solid salt, then filter it with suction, wash it with 99% ether three times, and store it at 60°C Vacuum drying is carried out to obtain the ylide;

[0034] Step 2 Acidification

[0035] The ylide is mixed with sulfuric acid, phosphoric acid, hydrochloric acid or p-toluenesulfonic acid, and the amount of the acid is equal to the amount of the ylide, and the ylide is rotated at 80°C for 4 hours to obtain a homogeneous ionic liquid monomer;

[0036] Step 3 Preparation of thiolated magnetic iron oxide core

[0037] Dissolve ferric chloride and ferrous chloride in distilled water at a molar ratio of 2:1. The amount of distilled water is 35 times the mass of ferric chloride. Afte...

Embodiment 2-6

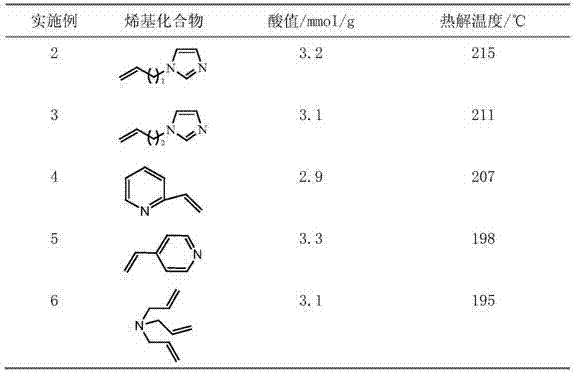

[0041] Except for the following differences, all the other are the same as in Example 1, and the alkenyl compounds are respectively as shown in Table 1, and the following results are obtained.

[0042] The alkenyl compound used in table 1 embodiment 2-6 and the catalyst parameter that obtains

[0043]

Embodiment 7-9

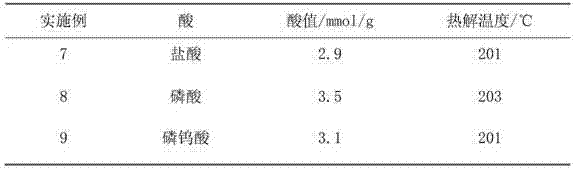

[0045] Except following difference, all the other are with embodiment 1, and different acid results are shown in table 2.

[0046] The acid used in table 2 embodiment 7-9 and the catalyst parameter that obtains

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com