Building energy-saving coating and its preparation method

A building energy-saving and coating technology, which is applied in the direction of epoxy resin coating, reflection/signal coating, coating, etc., can solve the problems of high reflectance, poor heat resistance of polystyrene microspheres, etc., and achieve sunlight reflection High ratio, excellent stability, effects of improving stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

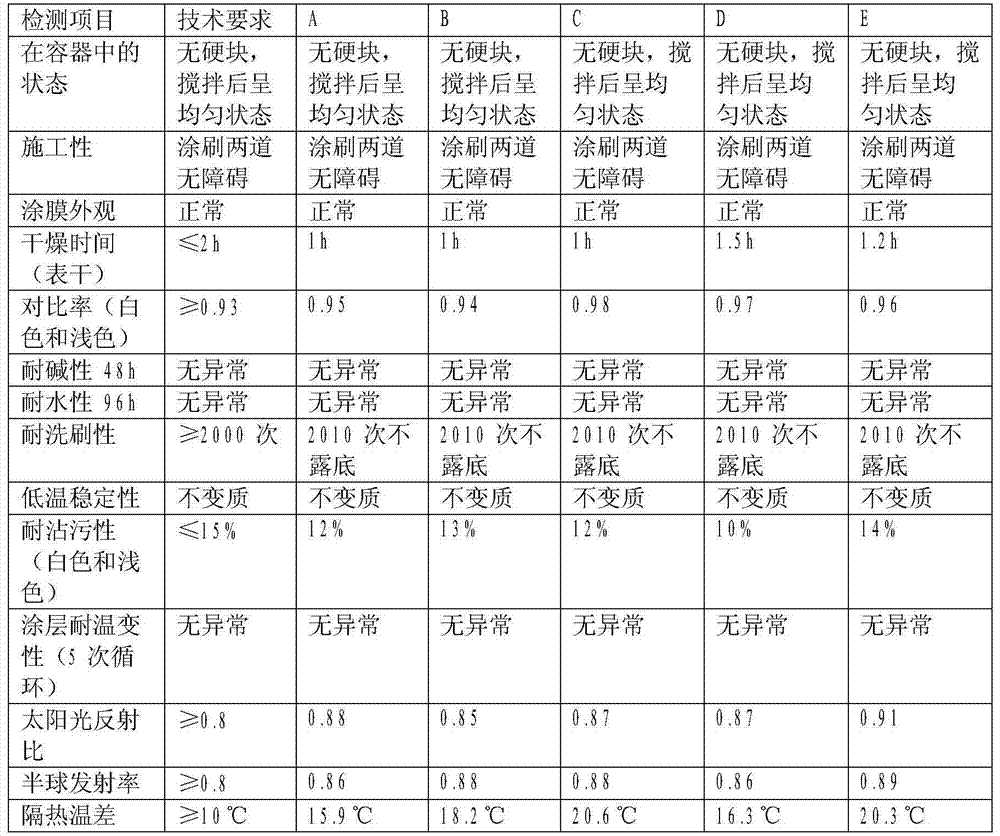

Examples

Embodiment 1

[0030] 1. Preparation of titanium dioxide-coated polystyrene composite microspheres

[0031]According to the weight ratio of components, add 32.9% deionized water, 60% purified styrene monomer solution (concentration ≥ 99.9%), 0.1% potassium persulfate, 3% KCL, and 4% acetone into the condensing reflux device in sequence 1. In the reaction kettle with a stirring paddle, nitrogen protection at room temperature is used to remove oxygen in the reactor and water. Set the rotation speed of the stirring paddle at 500r / min and stir for 20 minutes, then continue to pass nitrogen gas, and raise the temperature from room temperature to 70°C Finally, the rotation speed of the stirring blade was adjusted to 300r / min, and the monodisperse polystyrene microsphere emulsion was obtained by discharging after 24 hours of reaction.

[0032] Add 1 part of polystyrene microsphere emulsion and 10 parts of 98% concentrated sulfuric acid into the container according to the proportion by weight, and s...

Embodiment 2

[0037] 1. Preparation of titanium dioxide-coated polystyrene composite microspheres

[0038] Add 26.9% deionized water, 70% purified styrene monomer solution, 1% ammonium persulfate, 2% KCL, and 0.1% methanol into the reaction kettle connected with a condensing reflux device and a stirring paddle in turn, and nitrogen protection at room temperature In order to remove the oxygen in the reaction kettle and water, set the rotation speed of the stirring paddle at 300r / min and stir thoroughly for 10 minutes, then continue to pass nitrogen, and after the temperature rises from room temperature to 80°C, adjust the rotation speed of the stirring paddle to 300r / min, and react After 12 hours of discharging, a monodisperse polystyrene microsphere emulsion was obtained.

[0039] Add 1 part of polystyrene microsphere emulsion and 8 parts of chlorosulfonic acid into the container according to the proportion by weight, and stir for 3 hours after ultrasonic dispersion for 10 minutes, so that ...

Embodiment 3

[0044] 1. Preparation of titanium dioxide-coated polystyrene composite microspheres

[0045] Add 40% deionized water, 50% purified styrene monomer solution, 2% benzoyl peroxide, 4% KCL, and 4% glycerol into the reaction kettle connected with a condensing reflux device and a stirring paddle in sequence, and the room temperature Under the protection of nitrogen to remove the oxygen in the reaction kettle and water, set the rotation speed of the stirring paddle at 400r / min and stir for 15 minutes, then continue to pass nitrogen gas, and after the temperature rises from room temperature to 60°C, adjust the rotation speed of the stirring paddle to 250r / min, reacted for 30h and discharged to obtain a monodisperse polystyrene microsphere emulsion.

[0046] Add 1 part of polystyrene microsphere emulsion and 8 parts of sulfamic acid into the container according to the proportion by weight, and stir for 5 hours after ultrasonic dispersion for 15 minutes, so that the polystyrene microsp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com