Preparation method and application of bionic temperature-sensitive molecular engram composite film

A technology of molecular imprinting and composite membrane, applied in chemical instruments and methods, membrane technology, ion exchange, etc., to achieve the effects of good thermal stability, high effective imprinting specific surface area, and fast adsorption kinetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

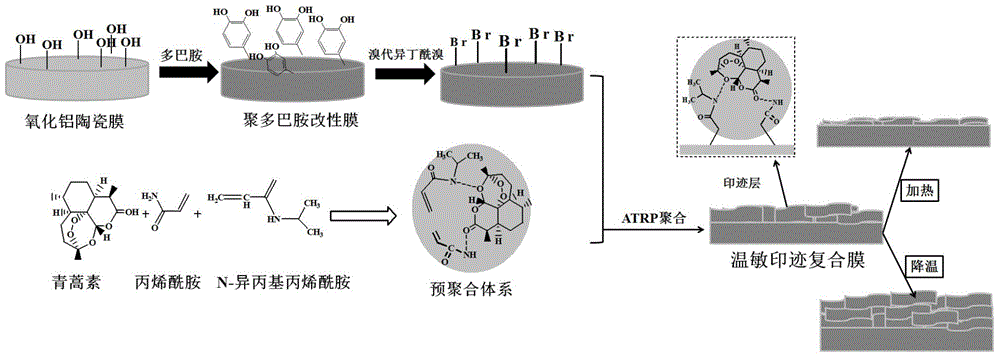

[0052] (1) Self-assembled polymerized porous alumina ceramic film on the surface of dopamine

[0053] First, configure 10mM tris(hydroxymethyl)aminomethane hydrochloride (Tris-HCl) aqueous solution, then adjust the pH value to 8.5, and dissolve dopamine (2mg / L) in the above 10mM Tris-HCl (pH=8.5) solution. Then a porous alumina ceramic membrane (Al 2 o 3 ) placed in the above solution, 25 ° C dopamine self-assembly modification for 16 hours, so that the polydopamine layer deposited on the Al 2 o 3 After the reaction, the surface was fully cleaned with distilled water, and then the gained polydopamine modified membrane (PDAAl 2 o 3 ) and dry at room temperature for later use.

[0054] (2) PDAAl 2 o 3 Surface Initiated Atom Transfer Radical Polymerization (ATRP) to Prepare Thermosensitive Imprinted Composite Membranes (TMICMs)

[0055] First, add 1 mL of bromoisobutyryl bromide (2-BIB) to 15 mL of refined tetrahydrofuran, mix well and add to the dropping funnel for later...

Embodiment 2

[0067] (1) Self-assembled polymerized porous alumina ceramic film on the surface of dopamine

[0068] First, configure 10mM tris(hydroxymethyl)aminomethane hydrochloride (Tris-HCl) aqueous solution, then adjust the pH value to 8.5, and dissolve dopamine (2mg / L) in the above 10mM Tris-HCl (pH=8.5) solution. Then a porous alumina ceramic membrane (Al 2 o 3 ) placed in the above solution, 25 ° C dopamine self-assembly modification for 16 hours, so that the polydopamine layer deposited on the Al 2 o 3 After the reaction, the surface was fully cleaned with distilled water, and then the gained polydopamine modified membrane (PDAAl 2 o3 ) and dry at room temperature for later use.

[0069] (2) PDAAl 2 o 3 Surface Initiated Atom Transfer Radical Polymerization (ATRP) to Prepare Thermosensitive Imprinted Composite Membranes (TMICMs)

[0070] First, add 1 mL of bromoisobutyryl bromide (2-BIB) to 15 mL of refined tetrahydrofuran, mix well and add to the dropping funnel for later u...

Embodiment 3

[0082] (1) Self-assembled polymerized porous alumina ceramic film on the surface of dopamine

[0083] First, configure 10mM tris(hydroxymethyl)aminomethane hydrochloride (Tris-HCl) aqueous solution, then adjust the pH value to 8.5, and dissolve dopamine (2mg / L) in the above 10mM Tris-HCl (pH=8.5) solution. Then the porous alumina ceramic membrane (Al 2 o 3 ) placed in the above solution, 25 ° C dopamine self-assembly modification for 16 hours, so that the polydopamine layer deposited on the Al 2 o 3 After the reaction, the surface was fully cleaned with distilled water, and then the gained polydopamine modified membrane (PDAAl 2 o 3 ) and dry at room temperature for later use.

[0084] (2) PDAAl 2 o 3 Surface Initiated Atom Transfer Radical Polymerization (ATRP) to Prepare Thermosensitive Imprinted Composite Membranes (TMICMs)

[0085] First, add 1mL of bromoisobutyryl bromide (2-BIB) to 15ml of refined tetrahydrofuran, mix well and add to the dropping funnel for later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com