Method for separating and purifying platinum metals through solvent extraction

A technology of platinum group metals and extraction method, which is applied in the direction of improving process efficiency, can solve the problems of harming human health, large amount of waste liquid treatment, and low separation efficiency, so as to improve product yield and quality, and reduce the cost of platinum and palladium. Effect of high loss and separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

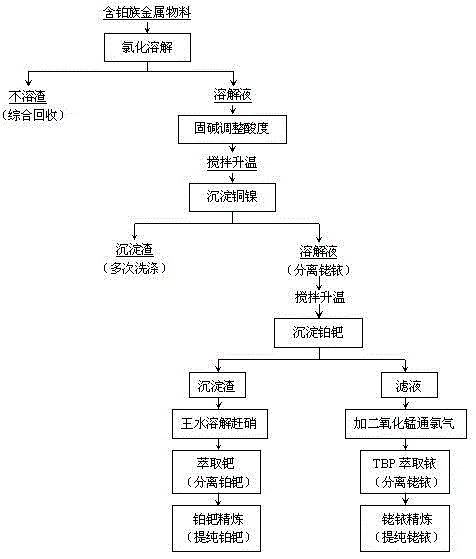

Image

Examples

Embodiment 1

[0029] Precious metal concentrate is chlorinated by chlorine gas (23L / h) for 40 minutes, the liquid-solid mass ratio is 4:1, then the acidity is adjusted to 2.5mol / L with hydrochloric acid, heated to 80°C by chlorine gas (25L / h) to dissolve, and the Time 8 hours. After finely filtering the solution to remove the insoluble residue, the volume of the filtrate is 400L (precious metal content is 18g / L), the solution is reinforced with alkali to adjust the pH value to 1, and when it is heated to 90°C, 14kg of ammonium oxalate is added under stirring, and a light blue color is immediately produced in the solution Color precipitated, and continued stirring and heating to 95 ° C when additional 0.5kg ammonium oxalate was added, no obvious precipitation was formed. Keep warm for 30 minutes, cool to 30°C and filter, wash the filter residue with 20L deionized water for 4 times, stir the filtrate and heat it to 70°C, then add 24kg of organic reducing agent vitamin C, at this time, a large...

Embodiment 2

[0031] The volume of the residual gold extraction solution is 500L (precious metal content is 20g / L), the solution is reinforced with alkali to adjust the pH value to 1.05, and when it is heated to 92°C, add 14kg of ammonium oxalate while stirring, and a light blue precipitate will immediately appear in the solution, and continue to stir and heat Add 0.6kg of ammonium oxalate to 95°C, no obvious precipitation is formed. Keep warm for 35 minutes, cool to 25°C and filter, wash the filter residue with 30L deionized water for 3 times, stir and heat the filtrate to 74°C, then add 24kg of organic reducing agent vitamin C, at this time, a large amount of gray-black precipitates are formed, keep warm and stir for 25 Minutes later, cool to 23°C and filter. The filter residue is washed 3 times with 30L deionized water. The filter residue is dissolved in aqua regia to adjust the acidity. After extracting palladium with diisoamyl sulfide to separate platinum and palladium, add 1.1kg di Ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com