Method for measuring molten salt chloride residues and recycling chemical components in regenerated substances

A technology of chemical composition and chloride, which is applied in the field of determination of chemical composition in molten salt chloride residues and recycled biomass, achieving good accuracy, simplifying operation steps, and shortening the inspection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] a. Preparation of the solution to be tested: Weigh the sample to be tested, dissolve the sample to be tested completely with dilute nitric acid solution, and dilute it with water to form a solution to be tested, wherein the sample to be tested is molten salt chloride residue or molten salt chloride The residue is regenerated, and the solid-liquid dilution ratio between the weighed mass of the sample to be tested in the solution to be tested and the diluted constant volume is 0.6 to 1.0 g / L;

[0020] b. Detection of chemical components: adopt inductively coupled plasma atomic emission spectrometry (ICP-OES) to measure the content of chemical elements in the solution to be tested, wherein the chemical elements are potassium, sodium, iron, magnesium, manganese, calcium, At least one of chromium, nickel, copper, cobalt, vanadium, titanium, lead, arsenic, silicon, phosphorus, and molybdenum.

[0021] The present invention adopts ICP-OES, which can quickly and simultaneously ...

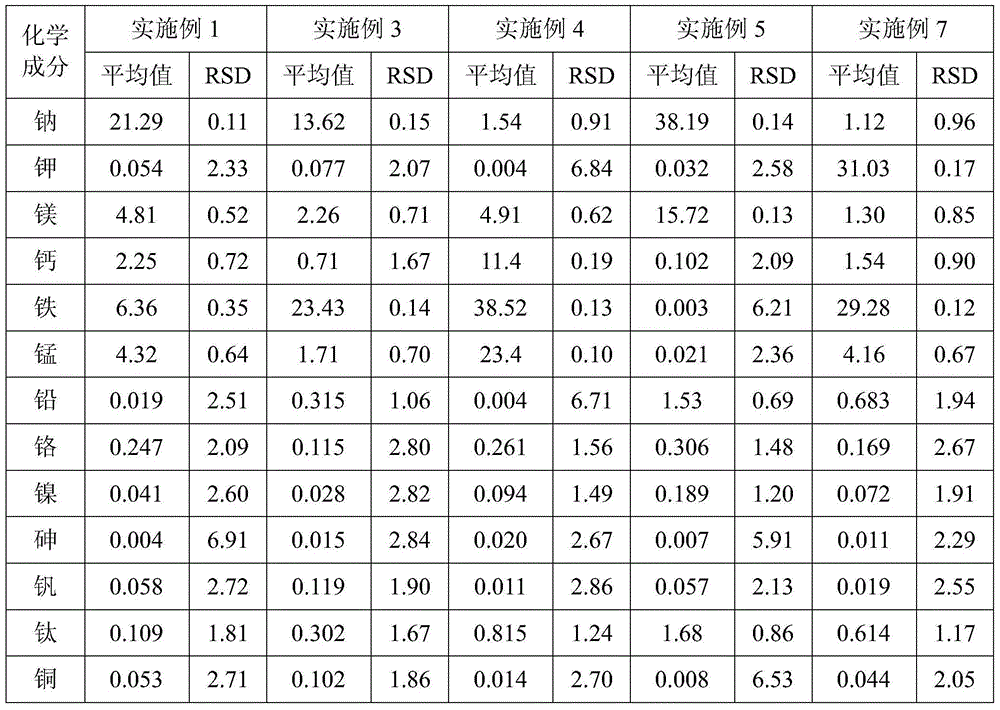

Embodiment 1

[0031] Weigh 0.2g of molten salt chloride residue, add 10mL (1+3) dilute nitric acid solution, heat at high temperature and quickly dissolve the sample until it is completely dissolved, dilute it with water and dilute it in a 200mL volumetric flask after cooling to form a sample solution to be tested, and use inductively coupled plasma Bulk atomic emission spectrometry (ICP-OES) directly determines the content of chemical elements such as potassium, sodium, iron, magnesium, manganese, calcium, chromium, nickel, vanadium, titanium, phosphorus, copper, and lead in the sample solution to be tested. Among them, the ICP-OES detection parameters were set as follows: RF radio frequency power 1050W, auxiliary gas flow rate 1.0L / min, peristaltic pump pump speed 60r / min, observation height 11.5mm, atomizer pressure 0.24MPa, measurement integration time 15s.

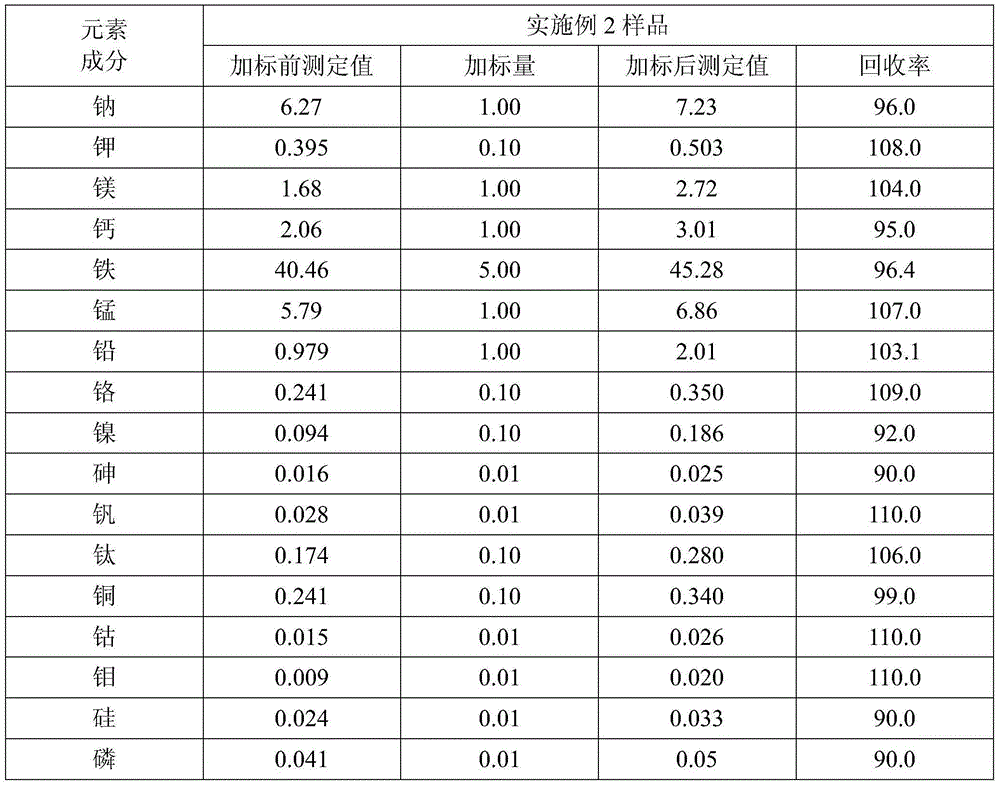

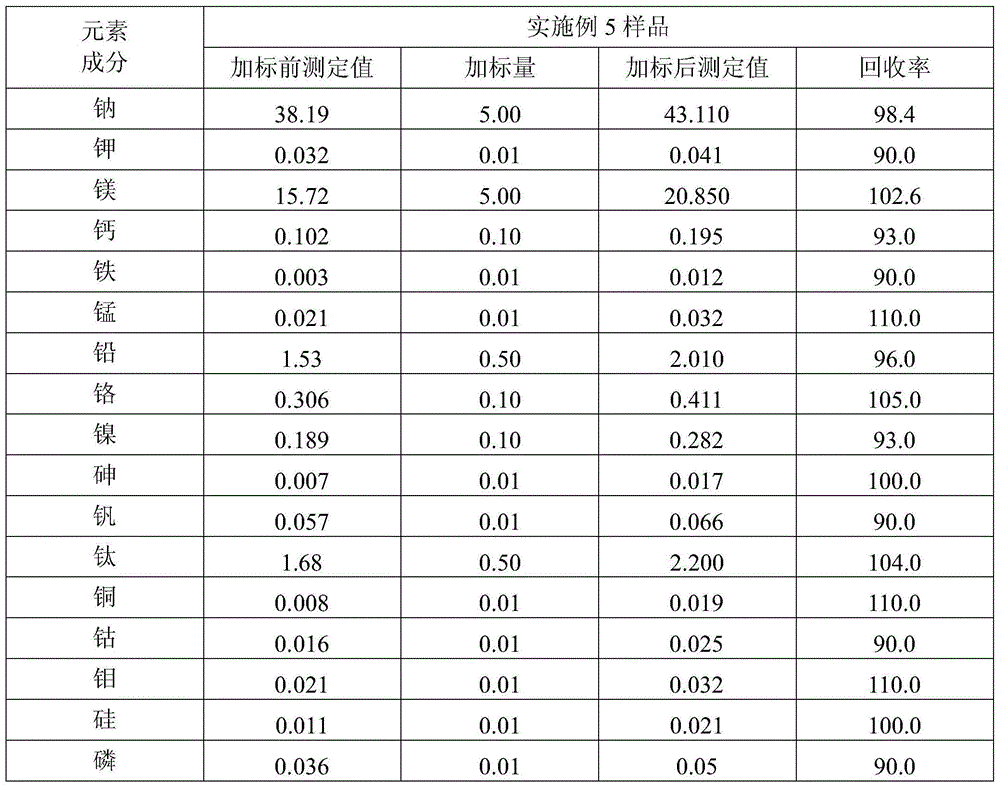

Embodiment 2

[0033] Weigh 0.3g of molten salt chloride residue, add 15mL (1+3) dilute nitric acid solution, the sample is completely dissolved and cooled, then diluted with water and fixed to volume in a 500mL volumetric flask to form a sample solution to be tested, using inductively coupled plasma atomic emission The spectroscopic method (ICP-OES) directly determines the content of chemical elements such as potassium, sodium, iron, magnesium, manganese, calcium, chromium, nickel, vanadium, titanium, phosphorus, copper, and lead in the sample solution to be tested. Among them, the ICP-OES detection parameters were set as follows: RF radio frequency power 1050W, auxiliary gas flow rate 1.0L / min, peristaltic pump pump speed 60r / min, observation height 11.5mm, atomizer pressure 0.24MPa, measurement integration time 15s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com