Method for preparing titanium niobate and carbon nanotube composite material and lithium ion capacitor with material as negative electrode

A technology of carbon nanotubes and composite materials, which is applied in the field of electrochemical material preparation and energy, can solve the problems of low electronic conductivity and restricted applications, and achieve the effects of high working voltage, uniform distribution, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] At room temperature, 1 mmol of niobium pentachloride and 2 mmol of isopropyl titanate were added to 20 mL of ethanol to disperse and mix, after stirring for 30 min, 230 mg of carbon nanotubes were added, and after stirring again for 30 min, the The mixed solution was poured into the inner lining of the reactor for solvothermal reaction. The reaction temperature was 200 °C, and the holding time was 24 h. After the reaction was completed and cooled to room temperature, the product was subjected to centrifugal drying treatment. 10 h. Afterwards, the dried samples were placed in a porcelain boat for two-step roasting treatment, the first roasting temperature was 300 °C, and the heating rate was 2 °C·min -1 , the holding time was 2 h, the sintering atmosphere was air; the second firing temperature was 700 °C, and the heating rate was 3 °C·min -1 , the holding time was 2 h, and the sintering atmosphere was nitrogen.

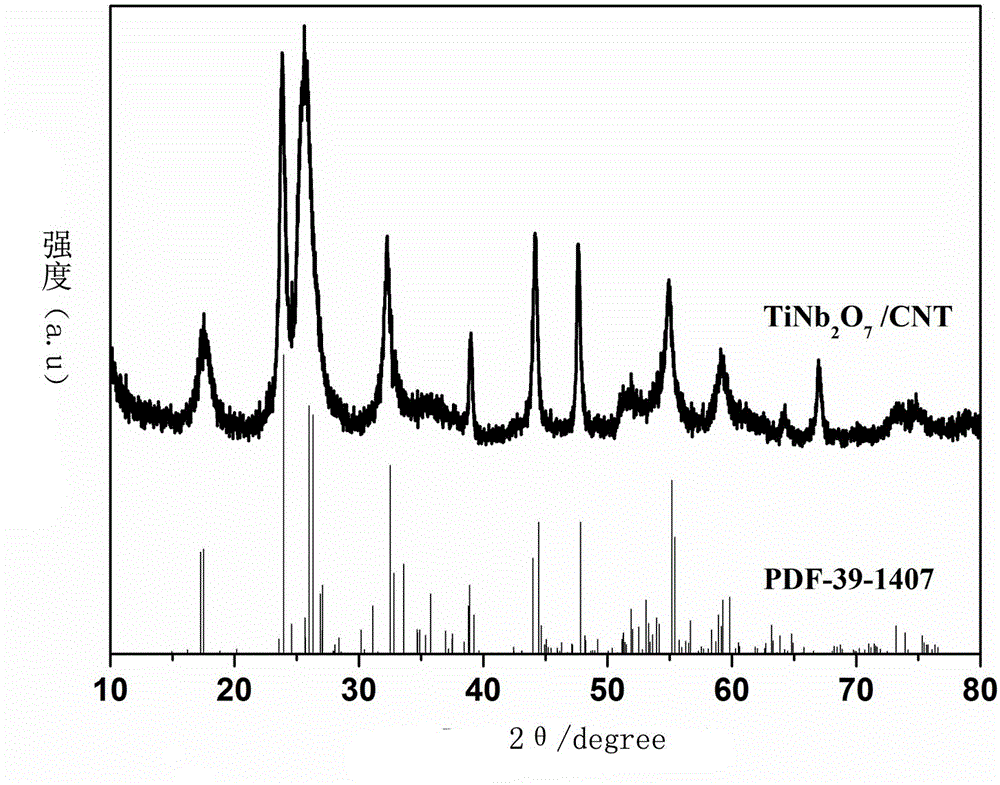

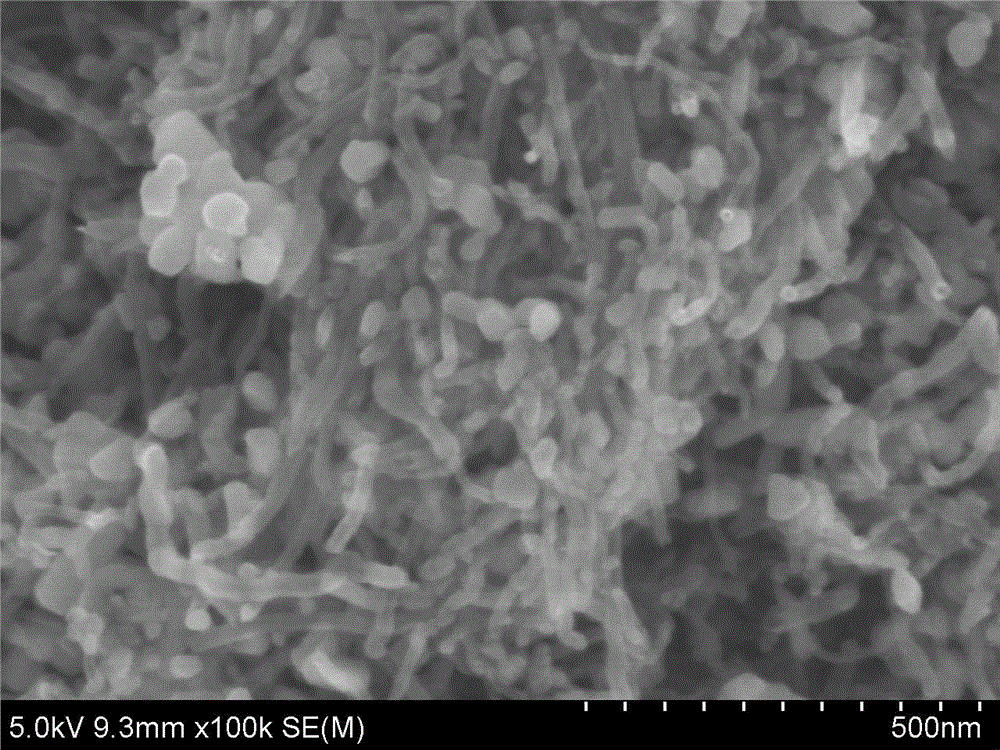

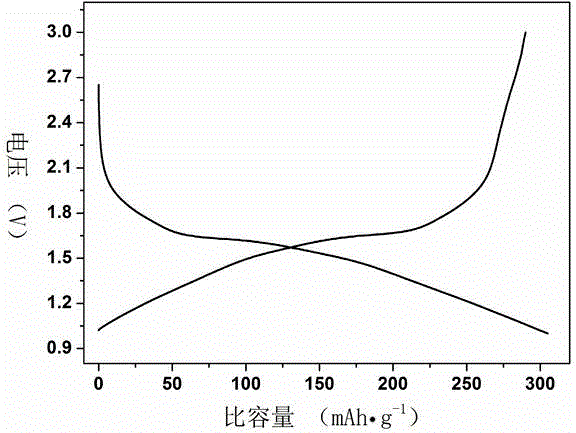

[0030] figure 1 XRD pattern of the titanium niobate / car...

Embodiment 2

[0038] At room temperature, 1 mmol of niobium pentachloride and 2 mmol of isopropyl titanate were added to 20 mL of dimethyl sulfoxide to disperse and mix. After stirring for 30 min, 230 mg of carbon nanotubes were added and stirred again for 30 min. After 1 min, the mixed solution was poured into the lining of the reactor for solvothermal reaction. The reaction temperature was 200 °C, and the holding time was 24 h. After the reaction was completed and cooled to room temperature, the product was subjected to centrifugal drying at 60 °C. , and the drying time was 10 h. Afterwards, the dried samples were placed in a porcelain boat for two-step roasting treatment, the first roasting temperature was 300 °C, and the heating rate was 2 °C·min -1 , the holding time was 2 h, the sintering atmosphere was air; the second firing temperature was 700 °C, and the heating rate was 3 °C·min -1 , the holding time was 2 h, and the sintering atmosphere was nitrogen.

Embodiment 3

[0040] At room temperature, add 1 mmol of niobium ethoxide and 2 mmol of isopropyl titanate into 20 mL of dimethyl sulfoxide to disperse and mix, stir for 30 min, add 230 mg of carbon nanotubes, and stir again for 30 min Finally, the mixed solution was poured into the inner lining of the reactor for solvothermal reaction, the reaction temperature was 200 °C, and the holding time was 24 h. After the reaction was completed and cooled to room temperature, the product was subjected to centrifugal drying treatment, and the drying temperature was 60 °C. The drying time is 10 h. Afterwards, the dried samples were placed in a porcelain boat for two-step roasting treatment, the first roasting temperature was 300 °C, and the heating rate was 2 °C·min -1 , the holding time was 2 h, the sintering atmosphere was air; the second firing temperature was 700 °C, and the heating rate was 3 °C·min -1 , the holding time was 2 h, and the sintering atmosphere was nitrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com