Esomeprazole magnesium enteric-coated tablet containing esomeprazole magnesium pellets and preparation method of esomeprazole magnesium enteric-coated tablet

A technology of esomeprazole magnesium pellets and meprazole magnesium enteric-coated tablets, which is applied in the field of esomeprazole magnesium enteric-coated tablets and its preparation, and can solve problems such as unfavorable patients taking it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

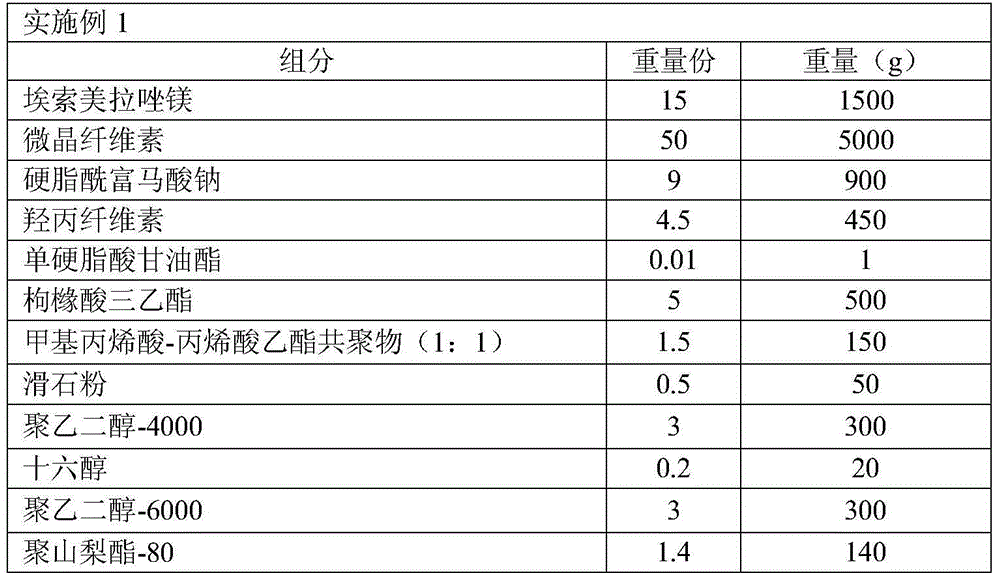

Embodiment 1

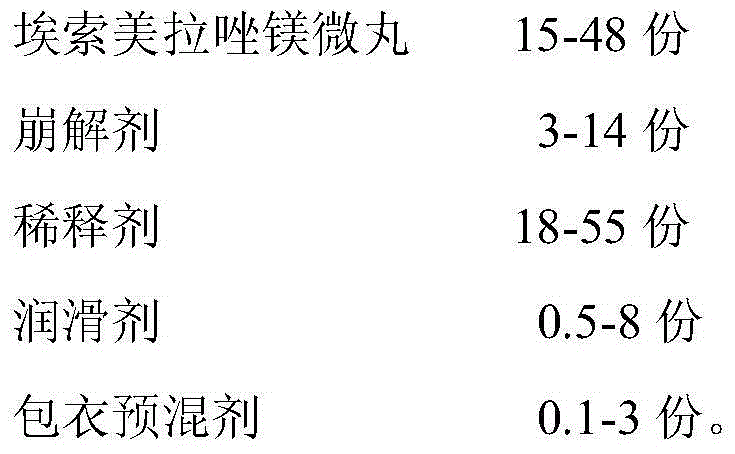

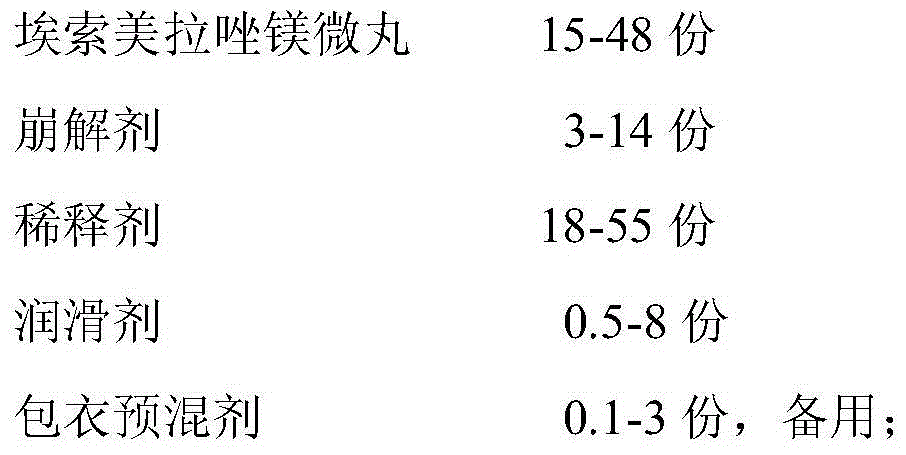

[0028] Components:

[0029]

[0030] Preparation:

[0031] (1) 1500g of esomeprazole magnesium, 5000g of microcrystalline cellulose, and 900g of sodium stearyl fumarate are pulverized through a 200-mesh sieve, mixed uniformly, and another 140g of polysorbate-80 is added to 50% ethanol solution, Make a 5% solution, as a binder, for subsequent use;

[0032] (2) Add the homogeneously mixed material in (1) into the centrifugal granulator, set the parameters as preheating temperature 40°C, air inlet temperature 30°C, peristaltic pump spray speed 3 rpm, powder supply speed 60 rpm , with an atomization pressure of 0.45Mpa, pelletized, dried and set aside;

[0033] (3) Pack the isolation layer, mix 450 g of hydroxypropyl cellulose and 1 g of glyceryl monostearate, add it into 95% ethanol solution to make a 15% solution, adjust the temperature to 30 ° C, and the spray pressure to 0.5 MPa, The liquid spraying speed is 4g / s, coating the pellets in (2), drying, controlling the moist...

Embodiment 2

[0037] Components:

[0038]

[0039] Preparation:

[0040](1) Grind 3000g of esomeprazole magnesium, 3000g of microcrystalline cellulose, and 100g of sodium stearyl fumarate through a 200-mesh sieve, mix well, and take another 800.2g of polysorbate-8, and add it to 50% ethanol solution , made into a 5% solution, as a binder, for subsequent use;

[0041] (2) Add the homogeneously mixed material in (1) into the centrifugal granulator, set the parameters as preheating temperature 40°C, air inlet temperature 35°C, peristaltic pump spray speed 7 rpm, powder supply speed 70 rpm , with an atomization pressure of 0.55Mpa, pelletized, dried, and set aside;

[0042] (3) Wrap an isolation layer, mix 10 g of hydroxypropyl cellulose and 700 g of glyceryl monostearate, add in 95% ethanol solution to make a 15% solution, adjust the temperature to 36 ° C, and spray pressure to 0.6 MPa, The liquid spraying speed is 4g / s, coating the pellets in (2), drying, controlling the moisture conten...

Embodiment 3

[0046] Components:

[0047]

[0048] Preparation:

[0049] (1) 4500g of esomeprazole magnesium, 7000g of microcrystalline cellulose, and 500g of sodium stearyl fumarate are pulverized through a 200-mesh sieve, mixed uniformly, and another 300g of polysorbate-80 is added to 50% ethanol solution, Make a 5% solution, as a binder, for subsequent use;

[0050] (2) Add the homogeneously mixed material in (1) into the centrifugal granulator, set the parameters as preheating temperature 40°C, air inlet temperature 40°C, peristaltic pump spray speed 12 rpm, powder supply speed 80 rpm , atomization pressure 0.68Mpa, pelletizing, drying, standby;

[0051] (3) Pack an isolation layer, mix 800 g of hydroxypropyl cellulose and 360 g of glyceryl monostearate, add in 95% ethanol solution to make a 15% solution, adjust the temperature to 40 ° C, and spray pressure to 0.78 MPa, The liquid spraying speed is 4g / s, coating the pellets in (2), drying, controlling the moisture content of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com