a co 2 Preparation method of catalyst for preparing propylene carbonate with propylene oxide

A technology of propylene carbonate and propylene oxide, which is applied in the field of catalyst preparation, can solve the problems of being unsuitable for a fixed bed process, the heterogeneous catalyst particles are small, and the active components are easily lost, and the cost of high activity stability and high temperature can be achieved. Highly active and favorable for loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 30 g of chlorine balls, 5 g of 1-methylimidazole and 180 g of toluene into a three-necked flask, and reflux at 110° C. for 24 hours. After filtration, it was washed three times with toluene, propylene carbonate and water respectively, and then vacuum-dried at 60° C. for 12 hours to obtain active component A1.

[0029] Grind and mix 18g of A1 with 12g of zinc bromide, 38g of phenolic resin and 3.8g of urotropine to make powder, and sieve at 120 mesh. Then tablet molding, the pressure during tablet pressing was 14MPa, and the holding time was 4 minutes to prepare the active precursor B1.

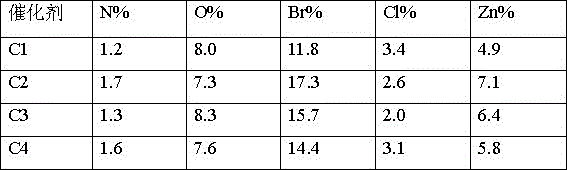

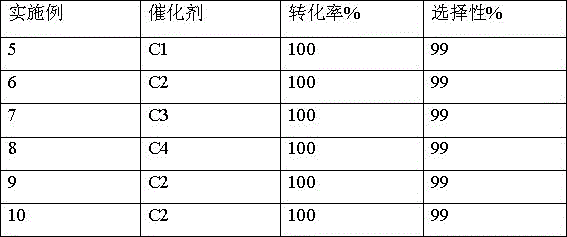

[0030] The active precursor B1 was heated at 180 °C for 2 hours under the protection of nitrogen. Then crush it into 20-40 mesh particles to make catalyst C1. The composition of catalyst C1 is listed in Table 1.

Embodiment 2

[0032] 30 g of chlorine balls, 10 g of 1-methylimidazole, and 180 g of toluene were added to a three-necked flask, and refluxed at 110° C. for 24 hours. After filtration, it was washed three times with toluene, propylene carbonate and water respectively, and then dried under vacuum at 60° C. for 12 hours to obtain active component A2.

[0033]Grind and mix 18g of A2 with 20g of zinc bromide, 40g of phenolic resin and 4.0g of urotropine to make a powder and sieve it at 120 mesh. Then tablet molding, the pressure during tablet pressing was 14MPa, and the holding time was 4 minutes to prepare the active precursor B2.

[0034] The active precursor B2 was heated at 180 °C for 2 hours under the protection of nitrogen. Then crush it into 20-40 mesh particles to make catalyst C2. The composition of catalyst C2 is listed in Table 1.

Embodiment 3

[0036] Add 30 g of chlorine balls, 10 g of 1-methylimidazole and 200 g of toluene into a three-necked flask, and reflux at 110° C. for 24 hours. After filtration, it was washed three times with toluene, propylene carbonate and water respectively, and then dried under vacuum at 60° C. for 12 hours to obtain active component A3.

[0037] Grind and mix 18g of A3 with 24g of zinc bromide, 60g of phenolic resin and 4.8g of urotropine to make a powder and sieve it at 120 mesh. Then tablet molding, the pressure during tablet pressing is 14MPa, and the time of holding is 4 minutes, and active precursor B3 is obtained.

[0038] The active precursor B3 was heated at 180° C. for 2 hours under the protection of nitrogen. Then crush it into 20-40 mesh particles to make catalyst C3. The composition of catalyst C3 is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com