Preparation method for high-gradient porous metal film

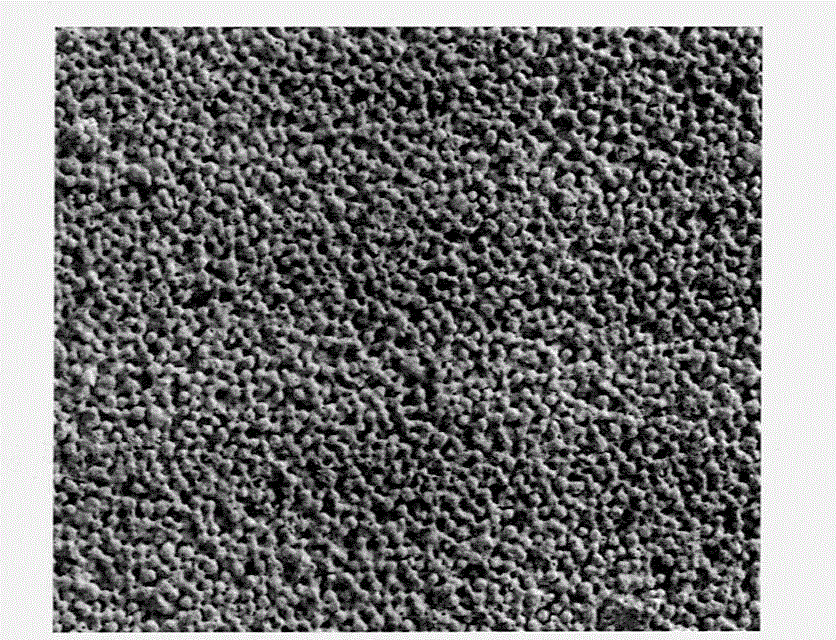

A porous metal, high gradient technology, applied in the field of metal film materials, can solve the problems of insufficient sintering, low pore gradient, easy collapse of the film layer, etc., and achieve the effect of improving the efficiency and effect of pore blocking and narrowing the particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) The substrate is a porous stainless steel disc with a diameter of 2 cm, a thickness of 0.15 cm, and an average pore size of 500 μm. The raw material is CaCO with an average particle size of 50 μm 3 Powder, use 6wt% polyvinyl butyral (PVB) ethanol solution as granulation binder, control gas velocity 2.0m / s, bed temperature 20°C, nozzle atomization pressure 0.2MPa, prefabrication by fluidization method Pore blocking material with an average particle size of about 500 μm. Dilute HNO with pH ≥ 4 is selected as the opening reagent 3 .

[0020] 2) Combine water with preformed CaCO 3 The plugging material is mixed in a certain proportion to make a paste (absolute viscosity value is 1000-2000cP), and then the paste is brushed onto the surface of the substrate, and repeatedly applied to plug the hole, then rinse the surface with water, repeat 3 times and then bake Dry it for later use, and then spray a small amount of PVB ethanol solution to fix it

[0021] 3) Grinding...

Embodiment 2

[0027] 1) A porous stainless steel tube is used as the substrate, with an inner diameter of 8 mm, an outer diameter of 12 mm, a length of 100 mm, and an average pore diameter of the substrate of 5 μm. The raw material is Al(OH) with an average particle size of 0.5 μm 3 Powder, use 6wt% polyvinyl butyral (PVB) ethanol solution as granulation binder, control gas velocity 2.0m / s, bed temperature 20°C, nozzle atomization pressure 0.2MPa, prefabrication by fluidization method Pore blocking material with an average particle size of about 5 μm. The opening reagent is NaOH solution with pH ≥ 12.

[0028] 2) Connect the porous stainless steel substrate with a vacuum pump to form a negative pressure component, place it in a fluidized pore-plugging material system for pore-plugging operation, and spray a certain amount of PVB ethanol solution to fix it.

[0029] 3) Polish the surface of the substrate with 1000-grit sandpaper to remove the plugging material on the surface.

[0030] 4...

Embodiment 3

[0035] 1) The selected substrate is a porous copper tube with an inner diameter of 10 mm, an outer diameter of 13 mm, a length of 100 mm, and an average pore diameter of the substrate of 20 μm. The selected raw material powder is 2μm ZnO, and 6wt% polyvinyl butyral (PVB) ethanol solution is used as the granulation binder, the gas velocity is controlled at 2.0m / s, the bed temperature is 20°C, and the nozzle atomization pressure is 0.2MPa, prefabricated pore blocking material with an average particle size of about 20μm by fluidization method. The reagent for opening the pores is H 2 SO 4 solution.

[0036] 2) Disperse 5g of prefabricated ZnO pore blocking material into 50ml of PVA aqueous solution, then use a circulating water pump to perform suction plugging operation on the substrate, control the suction pressure to -0.1MPa, then rinse with clean water to remove the ZnO on the surface, repeat the above operation 2 times, spray a certain amount of PVB ethanol solution on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Primary particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com