Organophosphorus modified waterborne polyurethane flame retardant coating agent and preparation method thereof

A technology of water-based polyurethane and flame-retardant coating, which is applied in fiber types, textiles and papermaking, fiber treatment, etc. It can solve the problems of impermeability to washing, easy migration, and large amount of flame retardants, so as to achieve good flame retardant effect and high The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The formula of organophosphorus modified waterborne polyurethane flame retardant coating agent is as shown in table 1:

[0025] Table 1 Example 1 The formulation of the environmentally friendly halogen-free organophosphorus flame-retardant modified water-based polyurethane fabric coating agent

[0026] raw material Dosage / g Isophorone diisocyanate 22.30 Polyether polyol (hydroxyl value 112mgKOH / g) 35.10 Organophosphorus polyols 6.19 Dimethylolpropionic acid 2.87 Triethylamine 2.05

[0027] [0027] Under nitrogen protection atmosphere and stirring conditions, the 22.30g isophorone diisocyanate, 35.10g polyether polyols with a hydroxyl value of 112mgKOH / g, and 6.19g organophosphorus polyols were placed in a flask, and preheated at 70°C. Poly 0.5h.

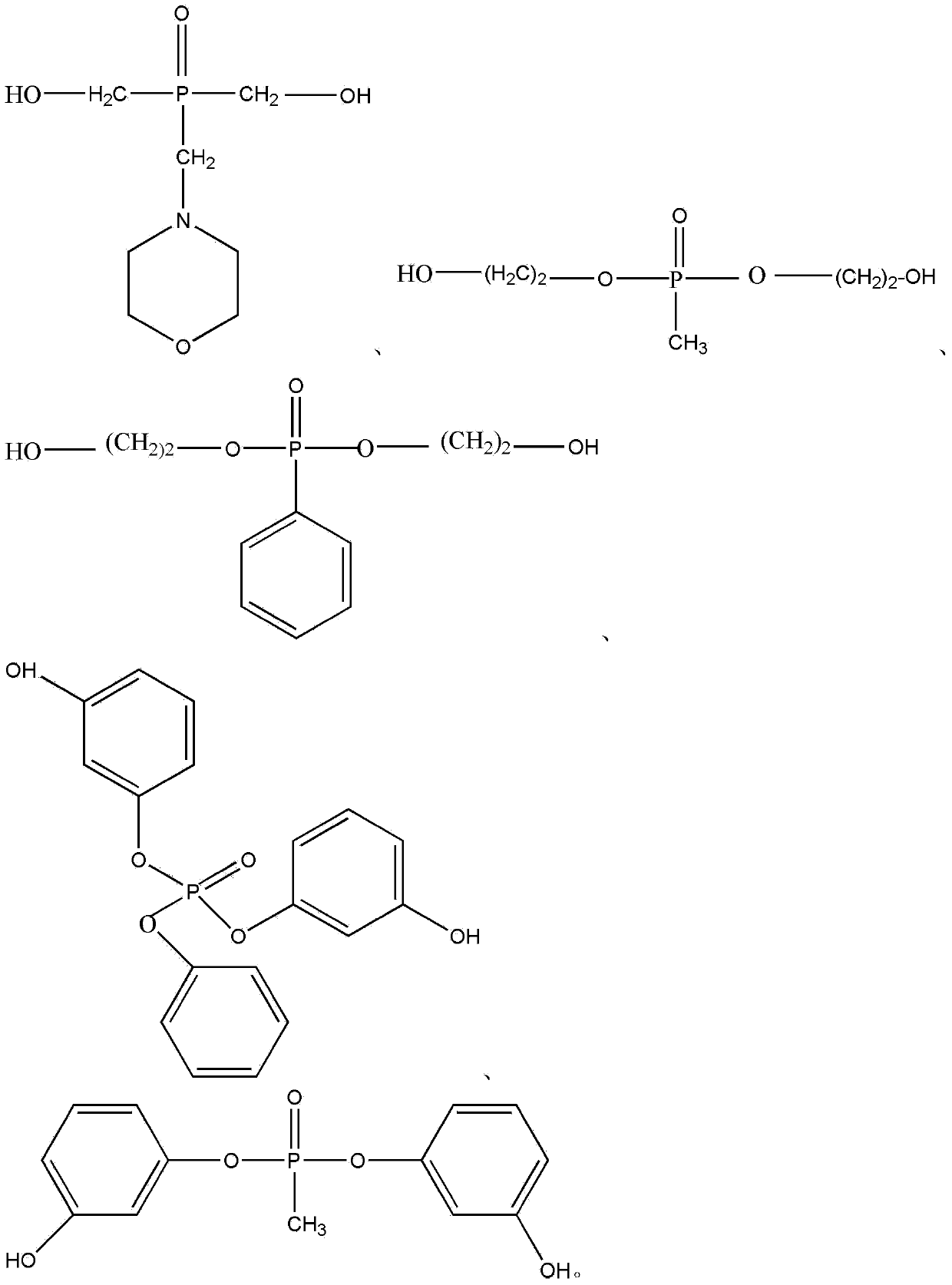

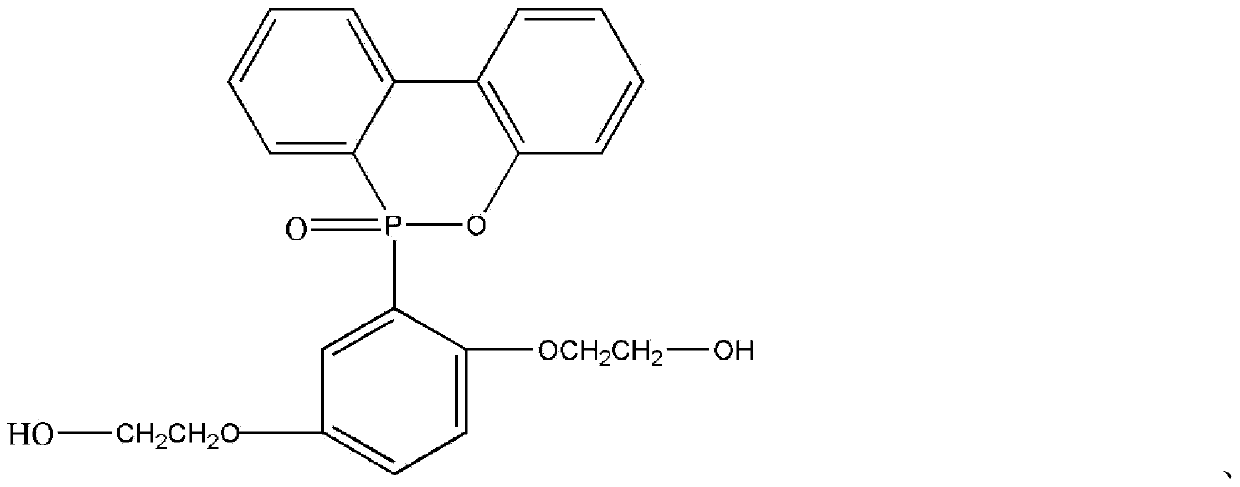

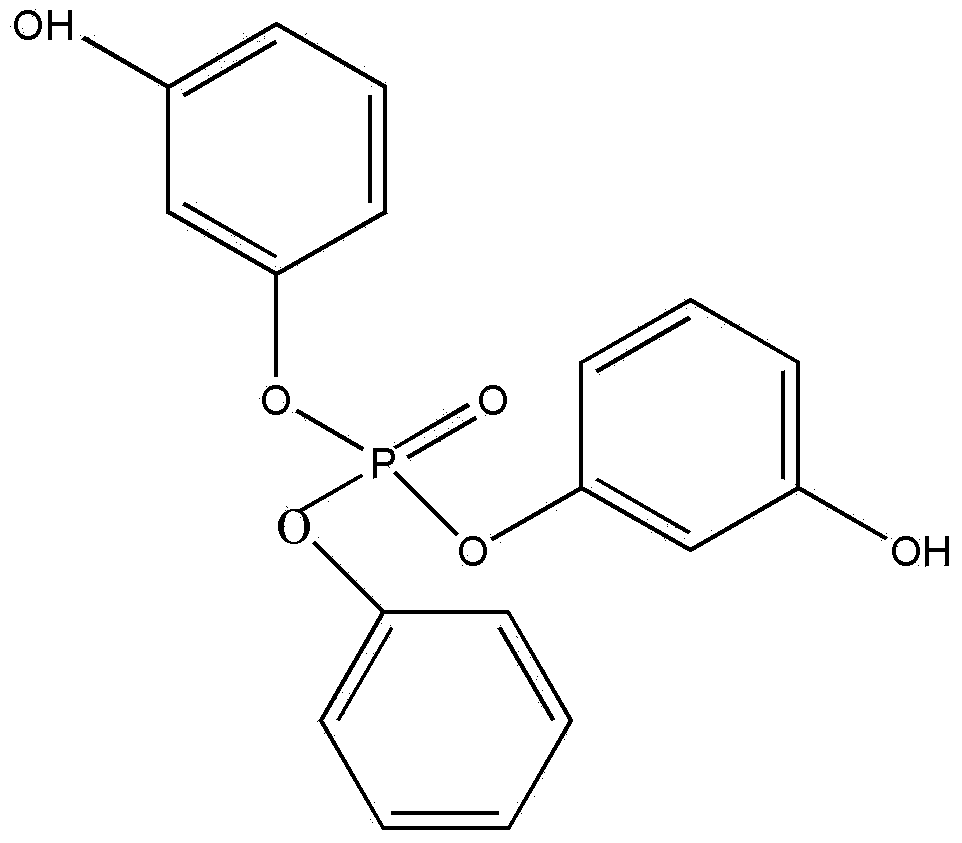

[0028] The structural formula of the organophosphorus polyol is:

[0029]

[0030] Add 2.87 g of the carboxylic acid-containing chain extender dimethylol propionic acid into t...

Embodiment 2

[0033] The formula of organophosphorus modified waterborne polyurethane flame retardant coating agent is as shown in table 2:

[0034] Table 2 Formula of Example 2 Environment-friendly Halogen-free Organophosphorus Flame Retardant Modified Waterborne Polyurethane Fabric Coating Agent

[0035] raw material Dosage / g Hexamethylene diisocyanate 25.34 Polyether polyol (hydroxyl value 95mgKOH / g) 32.70 Organophosphorus polyols 7.26 Sodium 1,4-butanediol-2-sulfonate 3.45 tributylamine 2.87

[0036] Under nitrogen protection atmosphere and stirring conditions, the 25.34g hexamethylene diisocyanate, 32.70g polyether polyol with a hydroxyl value of 95mgKOH / g, and 7.26g organophosphorus polyol were placed in a flask and preheated at 80°C. Poly 1h.

[0037] The structural formula of the organophosphorus polyol is:

[0038]

[0039] Add 3.45 g of the sulfonate-containing chain extender 1,4-butanediol-2-sodium sulfonate into the flask, and ex...

Embodiment 3

[0043] The formula of organophosphorus modified waterborne polyurethane flame retardant coating agent is as shown in table 3:

[0044] Table 3 Example 3 The formula of environment-friendly halogen-free organophosphorus flame retardant modified waterborne polyurethane fabric coating agent

[0045] raw material Dosage / g Toluene diisocyanate 27.12 Polyether polyol (hydroxyl value 112mgKOH / g) 33.48 Organophosphorus polyols 5.71 N-Methyldiethanolamine 3.54 ammonia 3.02

[0046] Under nitrogen protection atmosphere and stirring conditions, the 27.12g toluene diisocyanate, 33.48g polyether polyol with a hydroxyl value of 112mgKOH / g, and 5.71g organophosphorus polyol were placed in a flask, and prepolymerized at 60°C for 0.5h .

[0047] The structural formula of the organophosphorus polyol is:

[0048]

[0049] Add 3.54 g of the cationic chain extender N-methyldiethanolamine into the flask, and extend the chain at 60° C. for 2.5 h. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com