Preparation method of resin composition and prepreg, composite base material and pcb base material

A technology of resin composition and prepreg, which is applied in chemical instruments and methods, circuit substrate materials, synthetic resin layered products, etc., can solve the problems of increased substrate brittleness, reduced dielectric and heat resistance, and achieve high crosslinking density , High heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

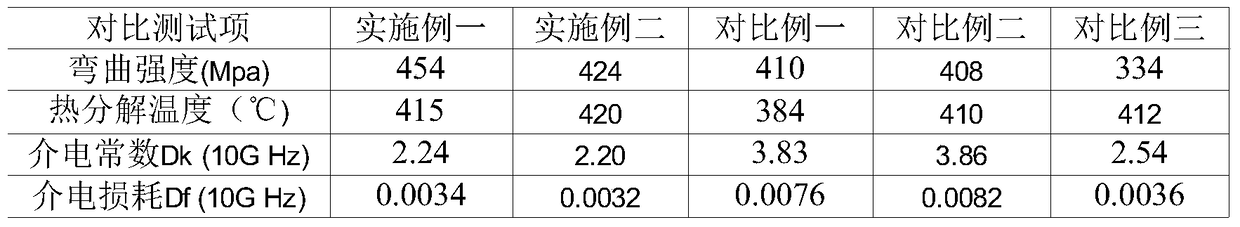

Examples

Embodiment 1

[0025] Take by weighing the bisphenol A type cyanate ester prepolymer of 90 weight parts, the polytetrafluoroethylene powder of 10 weight parts and the 2-methylimidazole (2-MI) of 0.02 weight part, add in the butanone of 66 weight parts Prepare a resin solution with a solid content of 60% (mass fraction), that is, in the resin solution, the mass ratio of each component is: bisphenol A cyanate prepolymer: polytetrafluoroethylene: 2-methylimidazole: Butanone=90:10:0.02:66. Dip 6 pieces (250mm*250mm) of 7628 quartz cloth into the above resin solution for impregnation, bake in an oven at 130°C for 2 minutes and then at 160°C for 5 minutes to make a semi-cured adhesive sheet. The gel time (G-T) of the splice is 105±15 seconds (171°C), and the fluidity is 25±5%. Superimpose and align the above 6 adhesive sheets, each with a 35μm copper foil on the top and bottom, in a vacuum press, at a temperature of 200°C and a pressure of 25kgf / cm 2 Conditions, pressed for 120 minutes to make a...

Embodiment 2

[0027] Take by weighing 70 parts by weight of dicyclopentadiene phenol type cyanate resin, 30 parts by weight of PFA (tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer) powder and 2-ethyl-4- Methylimidazole (2E4MI), join in the acetone of 66 weight parts and be made into the resin solution that solid content is 60%, i.e. in the resin solution, the mass ratio of each component is: dicyclopentadienol type cyanate resin: PFA:2E4MI:acetone=70:30:0.01:66. Dip 6 pieces (250mm*250mm) of 7628 quartz cloth into the above resin solution for impregnation, bake in an oven at 130°C for 2 minutes and then at 160°C for 5 minutes to make a semi-cured adhesive sheet. The gel time (G-T) of the splice is 105±15 seconds (171°C), and the fluidity is 25±5%. Superimpose and align the above 6 adhesive sheets, each with a 35μm copper foil on the top and bottom, in a vacuum press, at a temperature of 200°C and a pressure of 25kgf / cm 2 Conditions, pressed for 120 minutes to make a double-sided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com