Nanometer anti-freezing solution and preparation method thereof

An antifreeze and nanotechnology, applied in the field of antifreeze, can solve the problems of damage, tremor, and toxicity, and achieve the effects of low operating cost, easy degradation, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

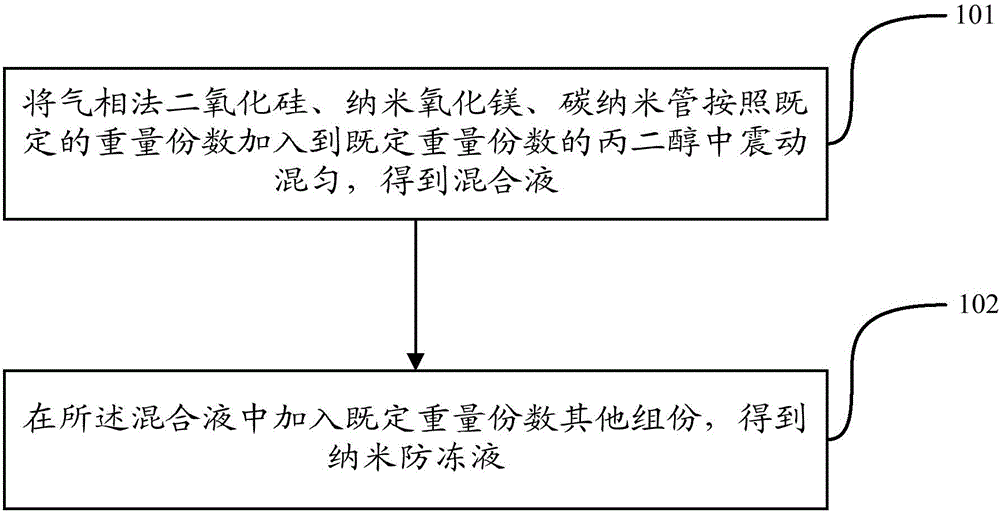

[0034] Please refer to figure 1 , the preparation method of the above-mentioned nano antifreeze that the present invention also provides, comprises the following steps:

[0035] Step 101: adding fumed silicon dioxide, nano-magnesia, and carbon nanotubes into propylene glycol in predetermined parts by weight and vibrating to obtain a mixed solution;

[0036] In step 101, the vibration mixing is specifically ultrasonic vibration.

[0037] Step 102: Add predetermined weight parts of other components into the mixed solution to obtain nanometer antifreeze solution.

[0038] The nanometer antifreeze provided by the present invention adopts propylene glycol as an antifreeze agent. The propylene glycol has a higher boiling point and its freezing point is much lower than ethylene glycol; the boiling point of the antifreeze can reach 140°C, so the antifreeze effect is better. More importantly, the toxicity and irritation of propylene glycol are very small, and it is easy to biodegrade...

Embodiment 1

[0041] The nano antifreeze solution provided by the embodiment of the present invention, in parts by weight, its raw material components include: 50 parts of propylene glycol, 5 parts of fumed silicon dioxide, 5 parts of nano-magnesia, 5 parts of carbon nanotubes, sodium hexametaphosphate 5 parts, 5 parts of borax, 5 parts of glycine, 5 parts of triethanolamine, 5 parts of epoxy resin, 10 parts of deionized water.

[0042] Among them, the particle size range of fumed silicon dioxide is 0.1 nm; the particle size of nano-magnesia is 0.1 nm; the radial size of carbon nanotubes is 1 nm, and the axial size is 1 micron.

[0043] Preparation

[0044] S11: adding fumed silicon dioxide, nano-magnesia, and carbon nanotubes into propylene glycol in predetermined parts by weight and ultrasonically vibrating to obtain a mixed solution;

[0045] S12: Adding predetermined weight parts of other components into the mixed solution to obtain a nano antifreeze solution.

Embodiment 2

[0047] The nano-antifreeze solution provided by the embodiment of the present invention, in parts by weight, its raw material components include: 92 parts of propylene glycol, 0.2 part of fumed silicon dioxide, 0.2 part of nano-magnesium oxide, 0.1 part of carbon nanotube, sodium hexametaphosphate 0.1 part, 0.1 part of borax, 0.1 part of glycine, 0.1 part of triethanolamine, 0.1 part of epoxy resin, 7 parts of deionized water.

[0048] Among them, the particle size range of fumed silicon dioxide is 100 nanometers; the particle size of nano-magnesia is 100 nanometers; the radial dimension of carbon nanotubes is 100 nanometers, and the axial dimension is 100 microns.

[0049] Preparation

[0050] S21: adding fumed silicon dioxide, nano-magnesia, and carbon nanotubes into propylene glycol in predetermined parts by weight and ultrasonically vibrating to obtain a mixed solution;

[0051] S22: Adding predetermined weight parts of other components into the mixed solution to obtain n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com