Preparation of supported sliver catalyst fibrous membrane and preparation method thereof

A silver catalyst, fiber membrane technology, applied in fiber treatment, spinning solution preparation, textile and papermaking, etc., can solve the problems of uneven size, irregular shape, difficult to obtain the improvement of activity and selectivity, etc. The effect of good performance, regular morphology and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

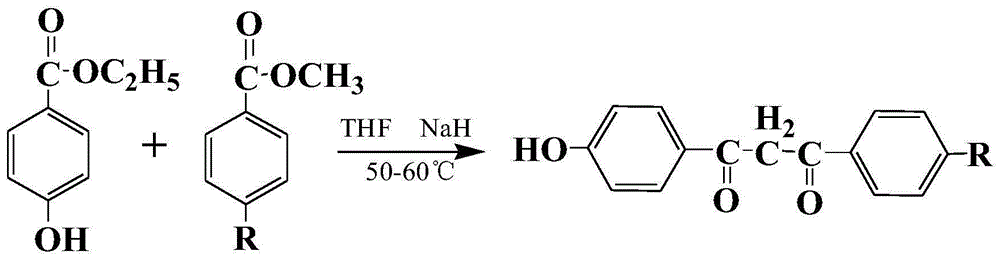

[0021] (1) Get 5mol of p-hydroxyacetophenone, R-substituted ethyl benzoate (R is selected from H, CH 3 or OCH 3 ) 6mol, be dissolved in the refining tetrahydrofuran of 200ml, add weight and be, the NaH of p-hydroxyacetophenone and ethyl benzoate gross mass 1% is as catalyst, NaH is dissolved in 80ml mixed solvent (petroleum ether: tetrahydrofuran=1:9 ), and control the drop rate into the reaction solution, after 1h dropwise, the temperature is controlled at 50-60°C for 36h. After the reaction is completed, first dissolve the filter residue in water, and adjust the pH=6-7, and use 2×400ml of acetic acid Ethyl extraction, and then at 35 ° C, after rotary evaporation of ethyl acetate, ethanol recrystallization to obtain monohydroxy β-diketone compounds.

[0022] Formula 1: R is selected from H, CH 3 or OCH 3

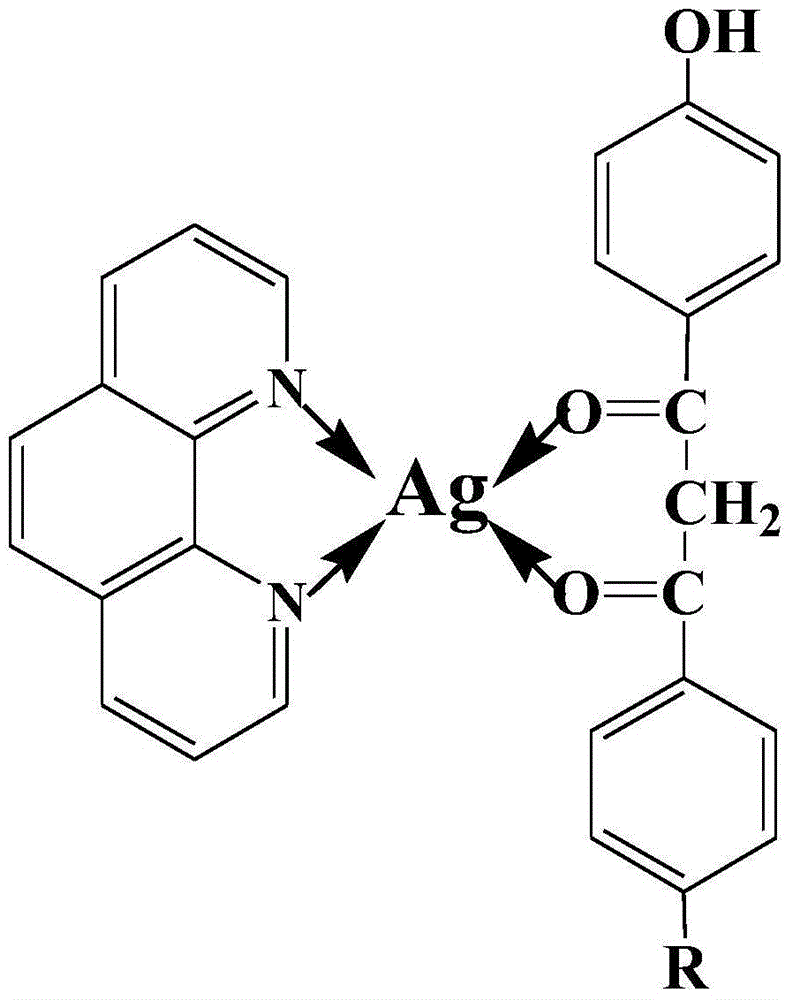

[0023] (2) Dissolve 1mol of silver nitrate inorganic salt, β-diketone compound obtained in step (1) containing 2mol of diketone groups, and 1mol of o-phenanthroline i...

Embodiment 2

[0027] The preparation method of β-diketone silver complex is as shown in Example 1, steps (1), (2),

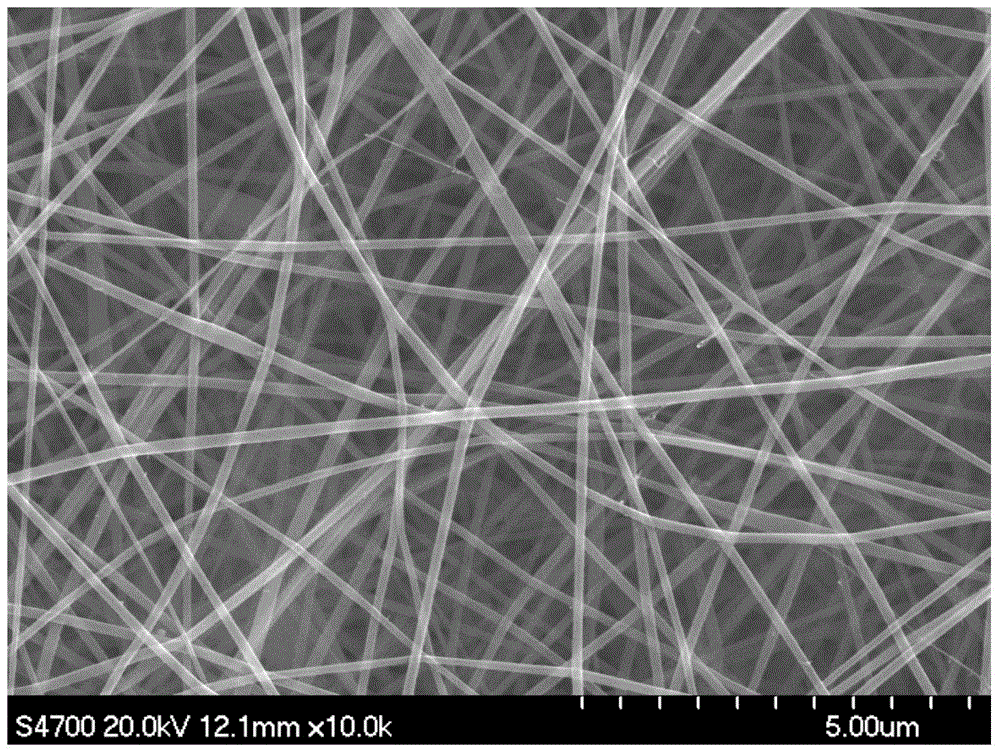

[0028] (3) Preparation of electrospinning solution: the N,N-dimethylformamide (DMF) solution of polyacrylonitrile (PAN) with a concentration of 10wt% is prepared, and after it is completely dissolved, the polymer content will be 30wt%. Add the β-diketone silver complex solution into the polymer solution, and obtain the electrospinning solution after it is completely dissolved;

[0029] (4) The electrospinning solution prepared in step (3) is electrospun, the spinning voltage is set to 15kV, the distance from the spinning port to the receiver is 20cm, the advancing speed of the syringe pump is 0.5mL / h, and the spinning Using a 9# needle, the silver-loaded silver catalyst fiber membrane was prepared by electrospinning.

Embodiment 3

[0031] The preparation method of β-diketone silver complex is as shown in Example 1, steps (1), (2),

[0032] (3) Preparation of electrospinning solution: the N,N-dimethylformamide (DMF) solution of polyacrylonitrile (PAN) with a concentration of 10wt% is prepared, and after it is completely dissolved, the polymer content will be 50wt%. Add the β-diketone silver complex solution into the polymer solution, and obtain the electrospinning solution after it is completely dissolved;

[0033] (4) The electrospinning solution prepared in step (3) is electrospun, the spinning voltage is set to 15kV, the distance from the spinning port to the receiver is 20cm, and the advancing speed of the syringe pump is 1mL / h. 9# needle, the silver-loaded silver catalyst fiber membrane was prepared by electrospinning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com