Coupling processing technology for steadily improving biodegradability of coking wastewater

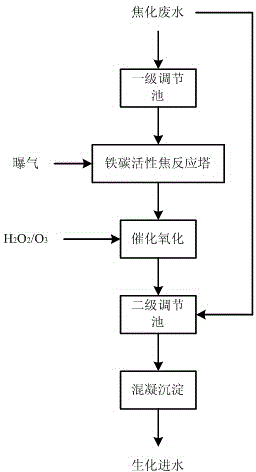

A technology for coking wastewater and treatment process, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of low ammonia nitrogen removal efficiency, difficult filler replacement, and heavy biochemical process load, etc. problems, to achieve good adsorption and flocculation effects, reduce operating costs, and improve biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

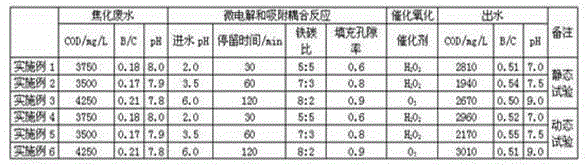

[0028] Take 50L of coking waste water from a coking plant for static test. The measured COD, biodegradability B / C and initial pH value are 3750mg / L, 0.18, and 8.0 respectively. 30L of it is adjusted for water quality, and the pH value is adjusted to 2.0 with sulfuric acid. Entering the iron-carbon activated coke reaction tower, the iron-carbon ratio of the iron-carbon activated coke is 5:5, the filling porosity is 0.6, blowing and aerating, the residence time is 30min, and 30% concentration of oxidant H is added dropwise to the effluent 2 o 2 20mL / L for catalytic oxidation for 10min, mixed 20L of untreated coking wastewater with it, stirred homogeneously, adjusted the pH value to 7.0, added dropwise 0.1wt% coagulant PAM, the addition amount was 0.6mg / L, and stood Precipitate, take the supernatant to measure COD, biodegradability B / C are 2810mg / L, 0.51 respectively, COD removal rate is 25.1%.

Embodiment 2

[0030] Take 50L of coking waste water from a coking plant for static test, measure COD, biodegradability B / C and initial pH value are 3500mg / L, 0.17, 7.9 respectively, 40L of which are adjusted for water quality, pH value is adjusted to 3.5 with phosphoric acid, Entering the iron-carbon activated coke reaction tower, the iron-carbon ratio of the iron-carbon activated coke is 7:3, the filling porosity is 0.8, blowing and aerating, the residence time is 60min, and 30% concentration of oxidant H is added dropwise to the effluent 2 o 2 10mL / L for catalytic oxidation for 45min, mixed 10L of untreated coking wastewater with it, stirred homogeneously, adjusted the pH value to 7.5, added dropwise 0.3wt% coagulant PAM, the addition amount was 0.1mg / L, let stand Precipitation, the supernatant was taken to measure COD and biodegradability B / C were 1940mg / L and 0.54 respectively, and the COD removal rate was 44.6%.

Embodiment 3

[0032] Take 50L of coking waste water from a coking plant for static test. The measured COD, biodegradable B / C and initial pH value are 4250mg / L, 0.21, and 7.8 respectively. 40L of it is adjusted for water quality, and the pH value is adjusted to 6.0 with tartaric acid. Enter the iron-carbon activated coke reaction tower, the iron-carbon ratio of the iron-carbon activated coke is 8:2, the filling porosity is 0.9, the blast aeration, the residence time is 60min, the effluent is passed into the ozone 3mg / L prepared by the ozone generator, and the Catalytic oxidation for 10 minutes, mixed with 10L of untreated coking wastewater, stirred homogeneously, and adjusted the pH value to 9.0, added dropwise 0.2wt% coagulant PAM, the addition amount was 0.3mg / L, stood for precipitation, took the The COD and biochemical B / C of the serum were determined to be 2670mg / L and 0.50 respectively, and the COD removal rate was 37.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com