Method for preparing surface-enhanced Raman spectrum substrate and substrate prepared by using method

A surface-enhanced Raman and spectroscopy technology, applied in the process of producing decorative surface effects, Raman scattering, manufacturing microstructure devices, etc., can solve the problem of not being able to provide sensitivity and stability at the same time, and achieve good sensitivity and stability. High stability, stable performance and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

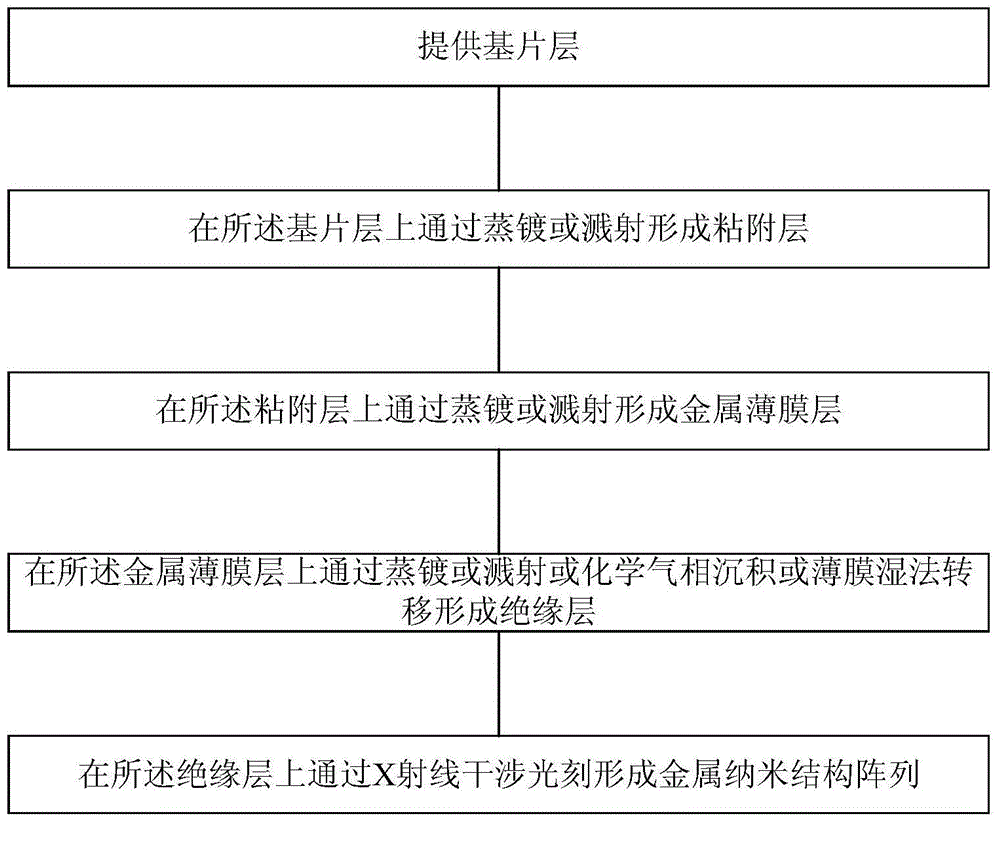

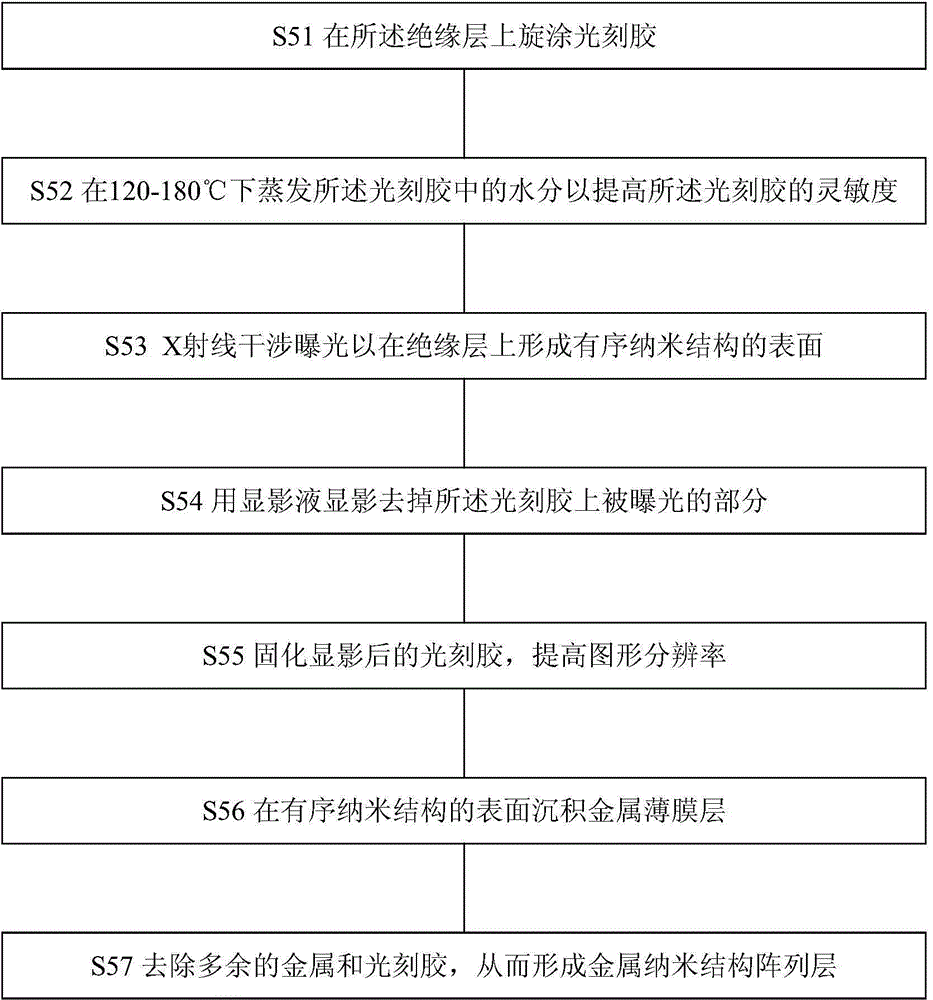

Method used

Image

Examples

Embodiment 1

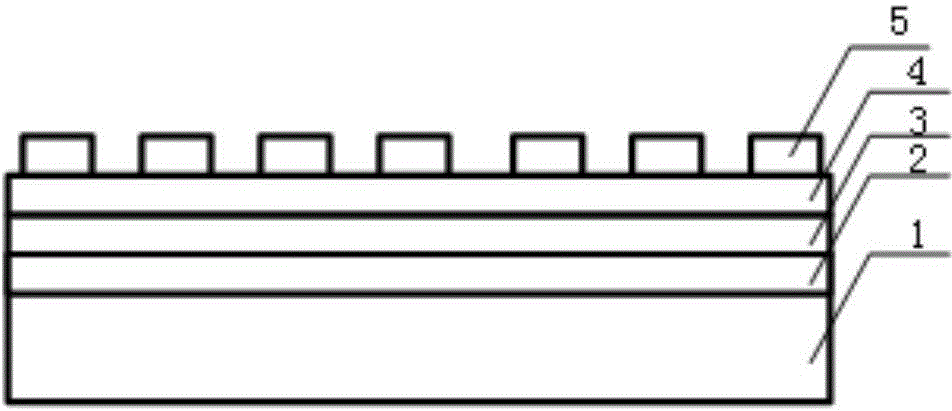

[0031] Put the 2-inch silicon substrate into acetone and anhydrous alcohol successively, and carry out surface cleaning with ultrasonic wave (ultrasonic frequency is 50Hz), after drying, use oxygen plasma bombardment (oxygen flow rate is 15sccm), plasma power is 100W , remove the organic matter on the surface of the substrate as the substrate layer 1;

[0032]Chromium was deposited on the substrate layer 1 with a thickness of 2 nm as the adhesion layer 2 by electron beam evaporation, and the pressure was 1×10 -7 Torr, power is 145W, deposition rate is 0.04nm / s;

[0033] A gold film with a thickness of 50 nm was deposited on the adhesion layer 2 by electron beam evaporation as the metal film layer 3, and the pressure was 1×10 -7 Torr, power is 115W, deposition rate is 0.12nm / s;

[0034] Deposition of SiO with a thickness of 10 nm on the metal thin film layer 3 by magnetron sputtering 2 As insulating layer 4, the pressure is 5×10 -3 Torr, power is 150W, deposition rate is 0....

Embodiment 2

[0039] Put the 2-inch silicon substrate into acetone and anhydrous alcohol successively, and carry out surface cleaning with ultrasonic wave (ultrasonic frequency is 50Hz), after drying, use oxygen plasma bombardment (oxygen flow rate is 10sccm), plasma power is 30W , remove the organic matter on the surface of the substrate as the substrate layer 1;

[0040] Using magnetron sputtering, 2nm thickness of titanium was evaporated on the substrate layer 1 as the adhesion layer 2, and the pressure was 5×10 -2 Torr, power is 100W, deposition rate is 0.24nm / s;

[0041] A silver thin film with a thickness of 50 nm was deposited on the adhesion layer 2 by magnetron sputtering as the metal thin film layer 3, and the pressure was 2.5×10 -3 Torr, power is 100W, deposition rate is 0.42nm / s;

[0042] 1.8 nm thick TiO deposited on metal thin film layer 3 by chemical vapor deposition 2 As the insulating layer 4, the temperature is 150°C, the flow rate is 20sccm, the time is 30 minutes, and...

Embodiment 3

[0046] Put the 2-inch silicon substrate into acetone and anhydrous alcohol successively, and carry out surface cleaning with ultrasonic wave (ultrasonic frequency is 50Hz), after drying, use oxygen plasma bombardment (oxygen flow rate is 10sccm), plasma power is 50W , remove the organic matter on the surface of the substrate as the substrate layer 1;

[0047] Chromium was deposited on the substrate layer 1 with a thickness of 2 nm as the adhesion layer 2 by electron beam evaporation, and the pressure was 1×10 -7 Torr, power is 145W, deposition rate is 0.14nm / s;

[0048] A gold film with a thickness of 100 nm was deposited on the adhesion layer 2 by electron beam evaporation as the metal film layer 3, and the pressure was 1×10 -7 Torr, power is 115W, deposition rate is 0.14nm / s;

[0049] Using thin film wet transfer method to deposit graphene as insulating layer 4 on metal thin film layer 3, including (1) spin-coating a layer of 200nm PMMA on graphene surface as protective la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com