Salt tolerant corrosion and scale inhibitor for underground oil-gas wells and preparation method thereof

A corrosion and scale inhibitor, technology for oil and gas wells, applied in wellbore/well components, chemical instruments and methods, earth-moving drilling, etc. It can achieve the effect of remarkable scale inhibition effect, firm adsorption film layer and strong salt resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] For oil well salt-resistant corrosion and scale inhibitors, the weight ratio of each component is:

[0036] Imidazoline derivatives: 40%;

[0037] Thiourea: 2%;

[0038] Hexamethylenetetramine: 2%;

[0039] Cetylpyridinium chloride: 3.5%;

[0040] Aminotrimethylenephosphonic acid (ATMP): 1.5%;

[0041] Hydroxyethylenediphosphonic acid (HEDPA): 1.5%;

[0042] Dodecyl dimethyl benzyl ammonium chloride (1227): 20%;

[0043] Methanol: 5%;

[0044] Water: 24.5%.

[0045]Preparation of imidazoline derivatives: first add 1440Kg of raw material oleic acid and 560Kg of polyethylene polyamine into the enamel reaction kettle, control the temperature at 100-110°C, stir well to make the mixture even, then slowly raise the temperature to 150°C, and react under vacuum for 1h . Add water-carrying agent xylene 100Kg to carry out acylation reaction for 2 hours, then slowly raise the temperature to 220°C to carry out cyclization reaction, and obtain an imidazoline intermediate aft...

Embodiment 2

[0054] For oil well salt-resistant corrosion and scale inhibitors, the weight ratio of each component is:

[0055] Imidazoline derivatives: 30%;

[0056] Thiourea: 2%;

[0057] Hexamethylenetetramine: 1.5%;

[0058] Cetylpyridinium chloride: 3.5%;

[0059] Aminotrimethylenephosphonic acid (ATMP): 5%;

[0060] Hydroxyethylenediphosphonic acid (HEDPA): 5%;

[0061] Dodecyl dimethyl benzyl ammonium chloride (1227): 25%;

[0062] Methanol: 5%;

[0063] Water: 23%.

[0064] The preparation process of imidazoline derivatives, the production method and evaluation reference standard of salt-tolerant corrosion and scale inhibitor for oil wells are the same as Example 1, and the code name is HZ-1B.

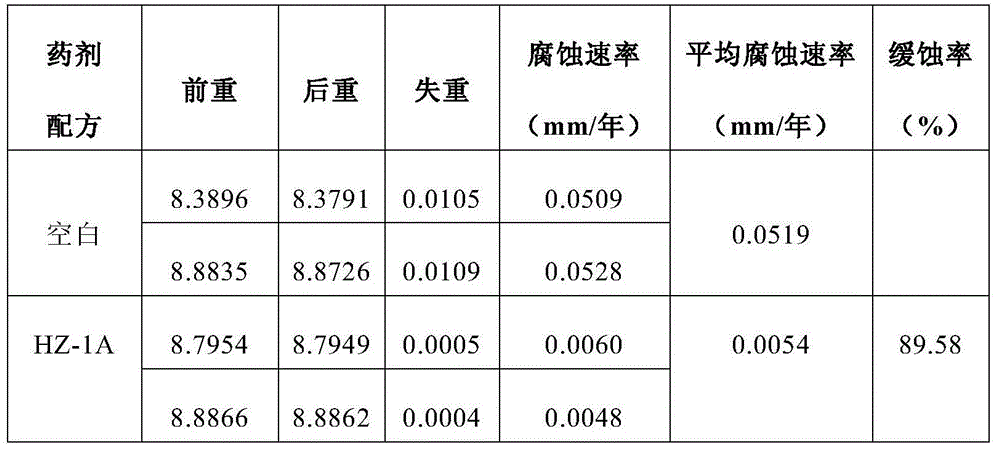

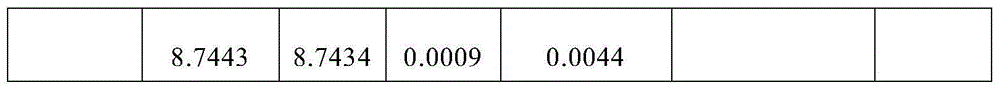

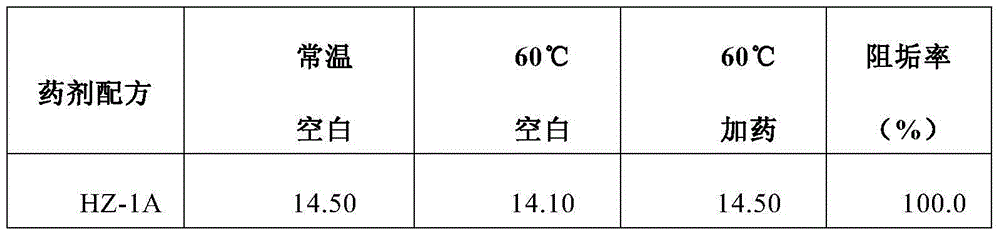

[0065] Effect of use: Performance evaluation is carried out by using oil well production fluid with a salinity of 125700mg / L, the water type is calcium chloride type, free CO 2 Concentration 26mg / L, H 2 The concentration of S is 0.36mg / L, and the pH value is 7.84. When the dosage ...

Embodiment 3

[0072] For oil well salt-resistant corrosion and scale inhibitors, the weight ratio of each component is:

[0073] Imidazoline derivatives: 35%;

[0074] Thiourea: 3%;

[0075] Hexamethylenetetramine: 1.5%;

[0076] Cetylpyridinium chloride: 4%;

[0077] Aminotrimethylenephosphonic acid (ATMP): 5%;

[0078] Hydroxyethylenediphosphonic acid (HEDPA): 5%;

[0079] Dodecyl dimethyl benzyl ammonium chloride (1227): 23%;

[0080] Methanol: 3%;

[0081] Water: 20.5%.

[0082] The preparation process of imidazoline derivatives, the production method and evaluation reference standard of salt-tolerant corrosion and scale inhibitor for oil wells are the same as those in Example 1, and the code name is HZ-1C.

[0083] Effect of use: The performance evaluation is carried out by using the oil well production fluid with a salinity of 153700mg / L. Water type is sodium bicarbonate type, free CO 2 Concentration 13mg / L, H 2 The concentration of S is 0.56mg / L, and the pH value is 6.51. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com