Method for preparing vasopressin tannate

A technology of vasopressin and tannic acid, applied in the direction of oxytocin/vasopressin, chemical instruments and methods, specific peptides, etc., can solve the problems of complex preparation process and low yield, and achieve the effect of optimizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 (HPLC method to detect the purity of crude vasopressin raw material and purified intermediate solution)

[0032] Instrument: Waters2695 / 2489 high performance liquid chromatography

[0033] Separation column: Agilent XDB-C184.6×250mm, 5μm

[0034] Mobile phase: A is 0.1% TFA aqueous solution in volume percentage, B is 0.1% TFA-50% acetonitrile aqueous solution in volume percentage

[0035] Flow rate is 1.0mL / min, detection wavelength is 214nm, room temperature detection,

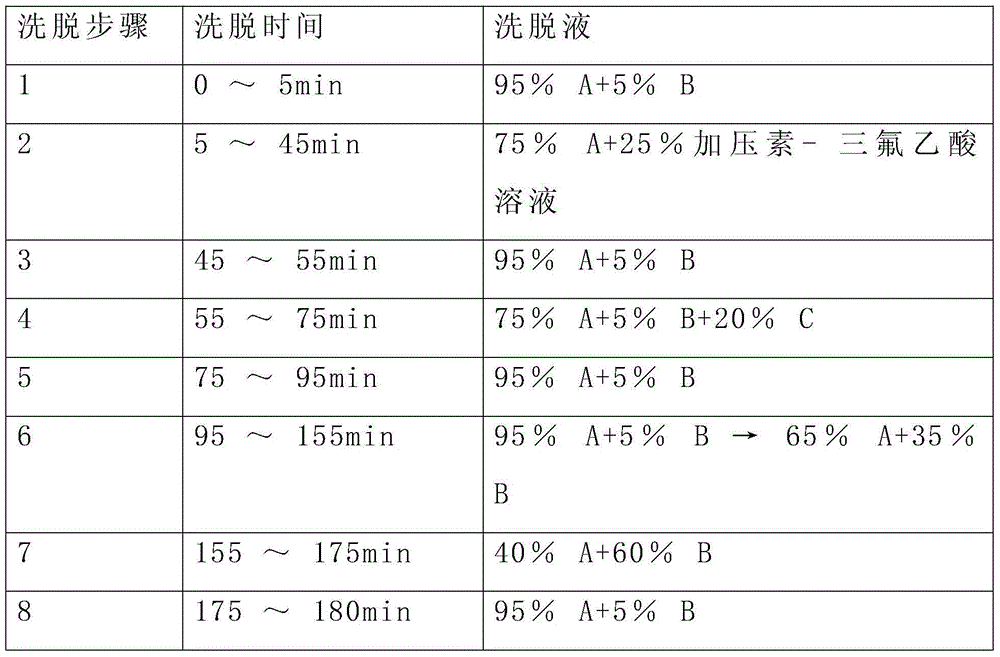

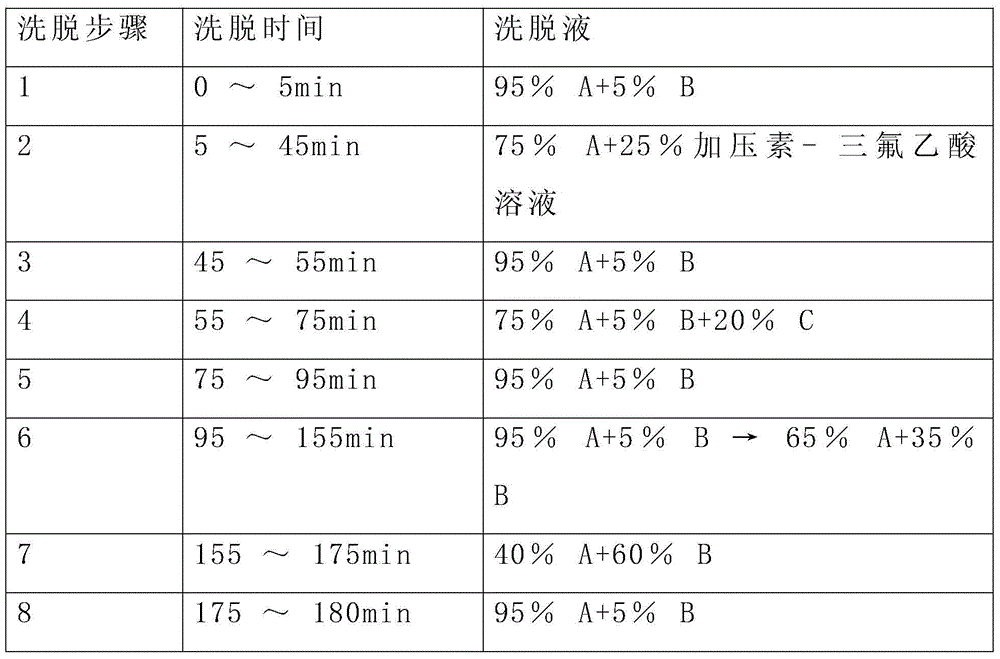

[0036] The elution gradient is shown in Table 1 below, and the percentages are volume percentages.

[0037] Table 1 Mobile phase elution ladder

[0038] Elution step Elution time eluent 1 0~5min 95%A+5%B 2 5~25min 95%A+5%B→50%A+50%B 3 25~30min 100%B 4 30~35min 95%A+5%B

Embodiment 2

[0039] Embodiment 2 (75mm inner diameter L&L4003 preparative column packing)

[0040] Using Load&Lock dynamic axial compression and static locking technology, the filler is styrene-divinylbenzene copolymer (reversed phase packing Agilent PLRP-S), the pore size is 10nm, the particle size is 10μm, and the column packing density is 0.33g / mL. The bed pressure is 650psi, Varian chromatographic packing system is used, 370g dry powder filler, 2L methanol is stirred and homogenized, poured into a 75mm inner diameter L&L4003 preparative column, the compression ratio is 3:1, the carrier gas is N2, and the carrier gas pressure is adjusted so that the oil pressure gauge pressure 2000psi, dynamic axial compression to a column bed height of 26cm, used as a preparative column for reverse-phase purification and reverse-phase desalting schemes.

Embodiment 3

[0041] Embodiment 3 (reverse phase purification of vasopressin crude product raw material)

[0042] Instrument: Varian SD-1 high pressure liquid phase preparation system

[0043] Chromatographic column: self-packed preparative column Load&Lock400375×260mm in Example 2, PLRP-S10μm10nm

[0044] Mobile phase: A is 0.1% trifluoroacetic acid aqueous solution by volume, B is 0.1% trifluoroacetic acid acetonitrile solution by volume, and the crude vasopressin is dissolved in 5% acetonitrile aqueous solution as solvent to prepare a 10g / L solution , after filtration and clarification, the sample liquid is mobile phase C, and its HPLC purity measured by the method of Example 1 is 88.13%, and the retention time is 14.40min.

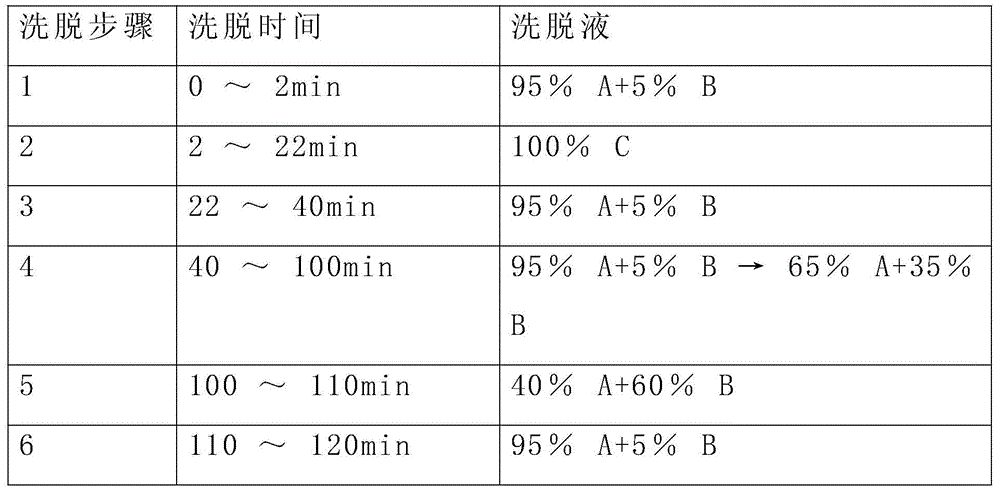

[0045] The reverse-phase purification conditions of this example are as follows: flow rate 200mL / min, detection at 220nm, purification and elution gradient as shown in the table below, and the main peak of the target with a retention time of 48-54min is collected a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com