Engineering bacteria and method for producing beta-alanine

A technology of engineering bacteria and aspartic acid, which is applied in the construction and application field of genetically engineered bacteria, can solve the problems of low yield and low activity of β-alanine, and the inability to achieve industrial production, so as to ensure the stability of enzyme activity, The effect of improving activity, saving cultivation cost and subsequent sewage treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1. Engineering bacteria expressing L-aspartate alpha carboxylase on the construction plasmid

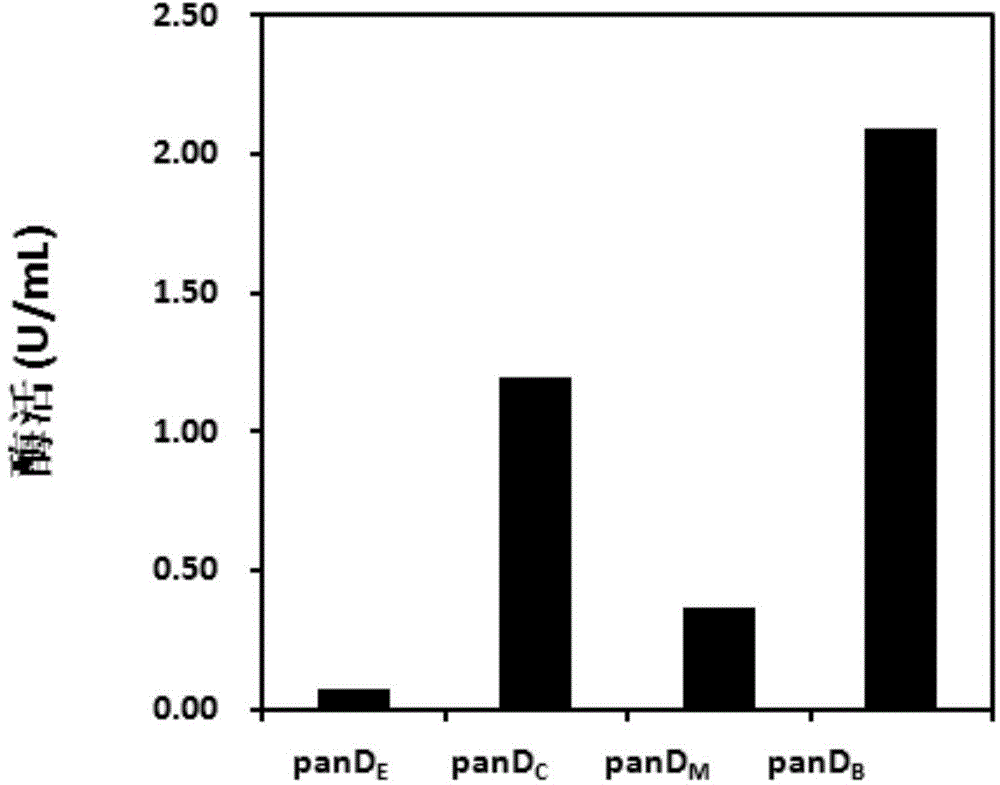

[0048] We selected L-aspartate α-carboxylase from four hosts, Escherichia coli, Corynebacterium glutamicum, Mycobacterium tuberculosis and Bacillus subtilis, respectively. The coding genes of 4 kinds of engineering bacteria were constructed. Wherein, the DNA sequence shown in Sequence 1 of the sequence listing is panD, the encoding gene of L-aspartate α-carboxylase in Escherichia coli BL21(DE)3 E . The DNA sequence shown in SEQ ID NO: 2 of the Sequence Listing is the gene panD encoding L-aspartate α-carboxylase in Corynebacterium glutamicum ATCC13032 C . The DNA sequence shown in Sequence 3 of the sequence listing is panD, the encoding gene of L-aspartate α-carboxylase in Mycobacterium tuberculosis H37Rv M . The DNA sequence shown in SEQ ID NO: 4 of the sequence listing is the gene panD encoding L-aspartate α-carboxylase in Bacillus subtilis 168 B .

[0049] 1. ...

Embodiment 2

[0101] Example 2. Detection of L-aspartate alpha carboxylase activity of engineered bacteria expressing L-aspartate alpha carboxylase on plasmids

[0102] The engineering bacteria A, engineering bacteria B, engineering bacteria C and engineering bacteria D constructed in Example 1 are respectively carried out as follows:

[0103] 1. Pick a single colony of the engineered bacteria, inoculate it in 10 mL of LB liquid medium containing 50 μg / ml kanamycin, and culture with shaking at 37°C and 200 rpm for 12 h.

[0104] 2. Take the entire culture system obtained in step 1, inoculate it into 100 mL of LB liquid medium containing 50 μg / ml kanamycin and 0.2 mM IPTG, and culture with shaking at 30° C. and 200 rpm for 12 h.

[0105] 3. The termination time of step 2 (ie OD 600nm = 3 bacterial solution), take 2 mL of culture solution, add 1 mL of pH 8.0, 0.01 mol / L phosphate buffer, mix well, and then ultrasonically disrupt (power 200W, work for 3 seconds and stop for 3 seconds, total t...

Embodiment 3

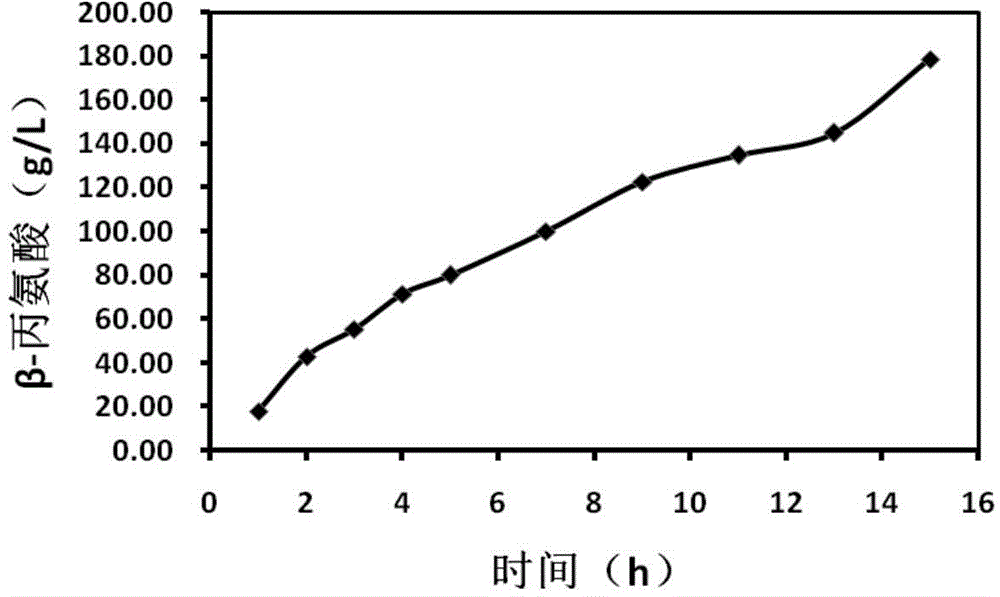

[0116] Embodiment 3, utilize engineering bacteria Ding to transform L-aspartic acid to produce β-alanine

[0117] 1. Pick a single colony of the engineered bacterial cells prepared in Example 1, inoculate it in 100 mL of LB liquid medium, and culture with shaking at 37° C. and 200 rpm for 12 h.

[0118] 2. Take the entire culture system obtained in step 1, inoculate it into 1000 mL of LB liquid medium containing 50 μg / ml kanamycin and 0.2 mM IPTG, and culture with shaking at 30° C. and 200 rpm for 12 h.

[0119] 3. Take the culture solution obtained in step 2, centrifuge at 9000 rpm for 10 min, and collect the bacterial cells.

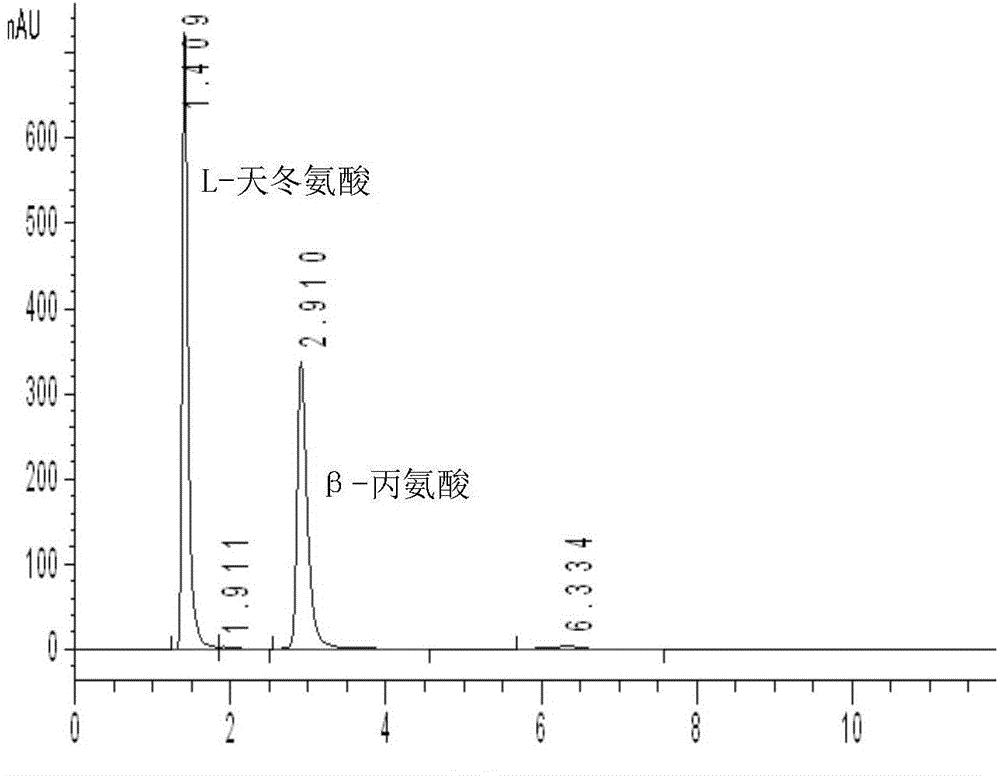

[0120] 4. Take all the cells obtained in step 3, suspend with 300 mL of distilled water, add L-aspartic acid (90 g), biotransform at 37° C., 450 rpm for 15 h, during the transformation process, sample once every hour, using the method in Example 2. Methods The concentration of β-alanine was detected by HPLC.

[0121] For test results see image 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com