Electrical Contact Materials And Method For Preparing The Same

An electrical contact material and metal technology, applied in conductive materials, conductive materials, circuits, etc., can solve the problems of complex preparation process and high preparation cost, and achieve the effect of reducing content, reducing preparation cost, excellent hardness and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

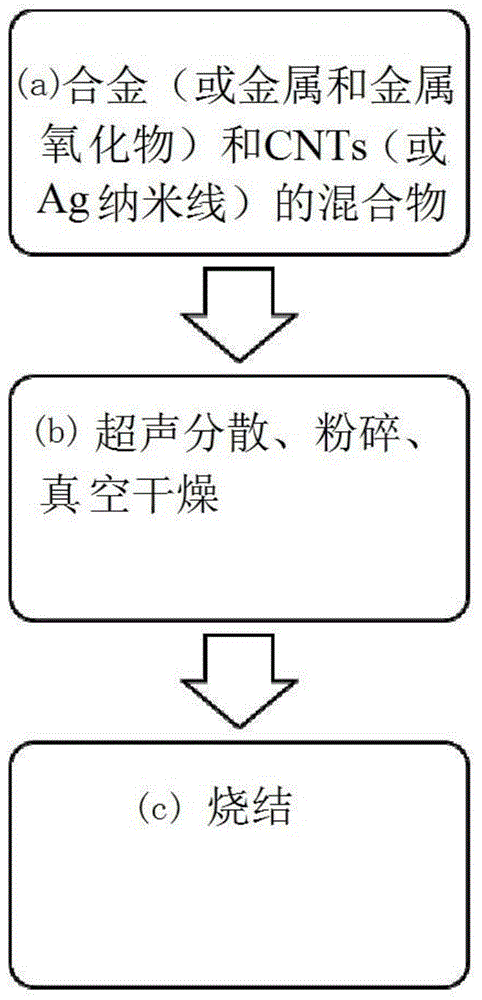

[0052] (5) Preparation of electrical contact materials

[0053] A method for preparing an electrical contact material according to the present invention includes: (a) by mixing (i) nickel (Ni) with one or more metals selected from silver (Ag), copper (Cu) and gold (Au) alloys, and (ii) Ag nanoparticles-coated CNTs, Ag-plated CNTs, or Ag nanowires to prepare a powder mixture, or by mixing (i) one or more metals selected from Ag, Cu, Ni, and Au , (ii) metal oxides, which are cadmium oxide, indium oxide, tin oxide, zinc oxide or mixtures thereof, and (iii) Ag nanoparticle-coated CNTs, Ag-plated CNTs or Ag nanowires to prepare a powdery mixture; (b) dispersing the powder mixture using sonication, and vacuum drying the dispersed powder mixture; and (c) sintering the vacuum dried powder mixture. figure 2 A method of making the electrical contact material is shown.

[0054] Hereinafter, a method of preparing the electrical contact material will be described in detail.

[0055] (5...

Embodiment approach 1

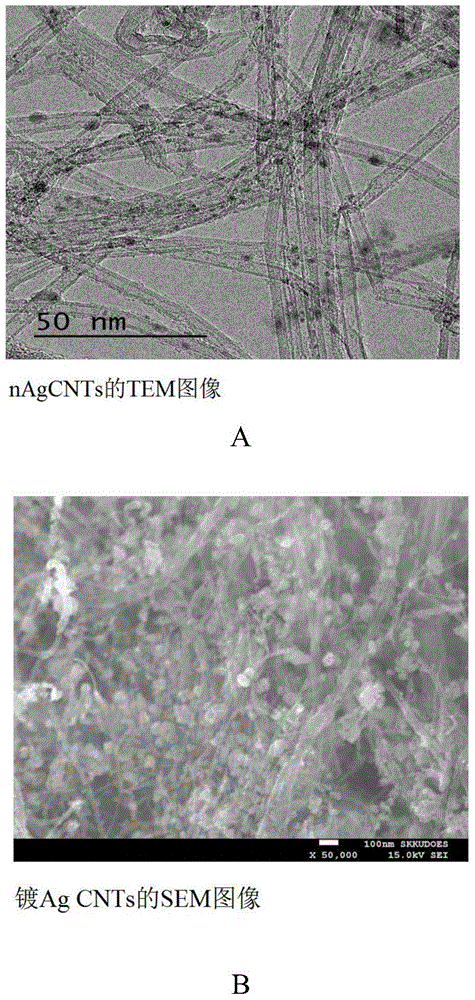

[0073] 1-1. Preparation of nAgCNTs

[0074] AgNO 3 Ag nanoparticles were formed by dissolving in ethanol for 1 hour with a stirrer using a magnetic bar and then stirring for 3 days with a small amount of benzyl mercaptan added to the ethanol. Ag nanoparticles bound to benzyl groups donated by the benzylthiol were bound to CNTs within hours when water-bath-type sonication was performed.

[0075] 1-2. Preparation of Ag-Ni-nAgCNTs

[0076] After immersing nAgCNTs (0.1 wt%) with micro-sized Ag powder (59.9 wt%) and Ni powder (40 wt%) in ethanol, ultrasonic treatment was used to uniformly disperse each of the nAgCNTs, Ag powder, and Ni powder. One. After combining the dispersed solutions, the combined solutions were dispersed again using sonication. The dispersed mixture powder was separated from the solvent using vacuum filtration and dried under vacuum. The dried powder is pulverized to finally obtain a mixture powder.

[0077] Using the SPS, the mixture powder was filled i...

Embodiment approach 2

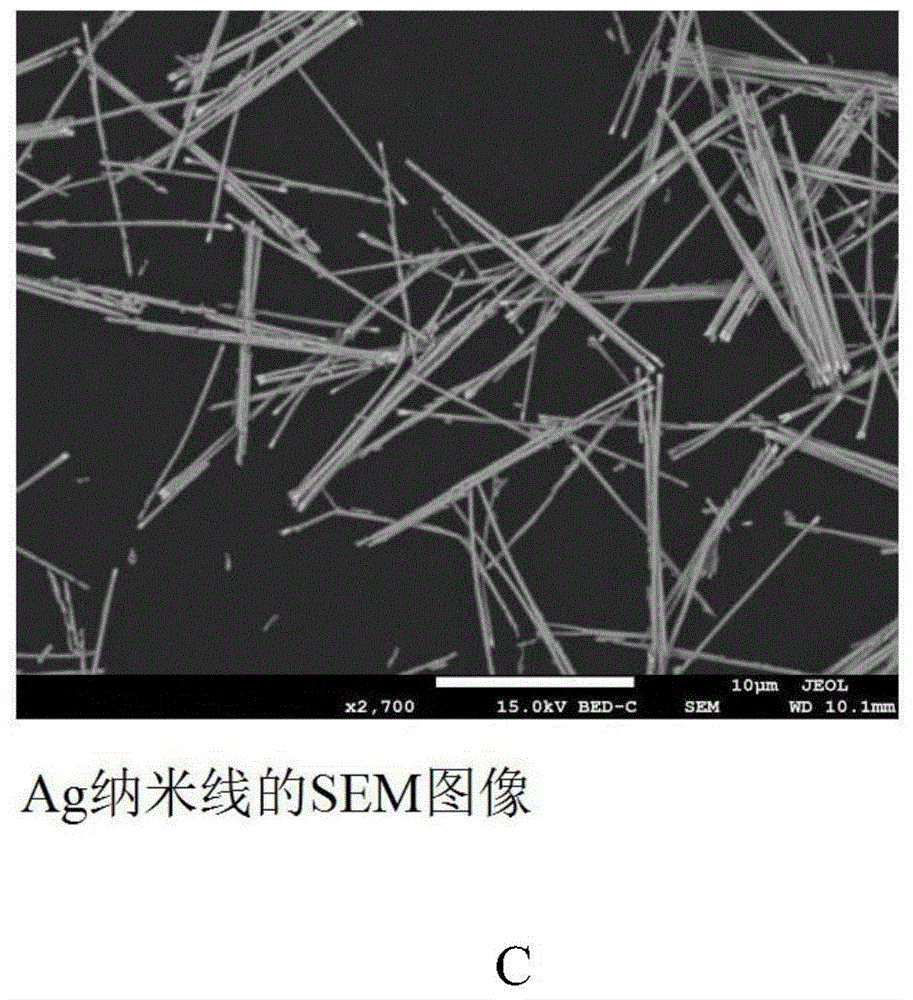

[0079] 1 wt% Ag-coated CNTs and 59 wt% micro-sized Ag powder were used. A sintered body was prepared in the same manner as Embodiment Mode 1 except that the sintering temperature was 750°C. The Ag-plated CNTs have a diameter of 20 to 80 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com