A method and device for removing siloxane in landfill gas/biogas

A technology of gas siloxane and landfill gas, applied in separation methods, chemical instruments and methods, gas fuels, etc., can solve the problems of high cost and high energy consumption, achieve large processing load, simple operating conditions, and optimize energy structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

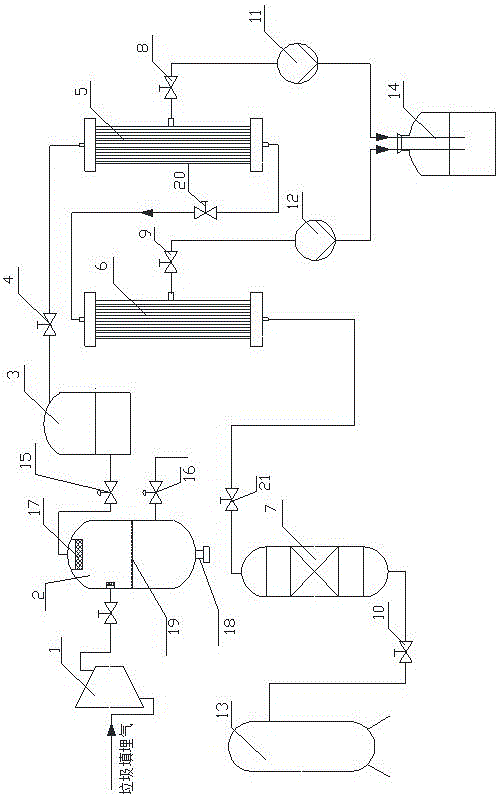

[0030] The siloxane concentration is 120mg / Nm 3 After the landfill gas temperature is controlled at 20°C, it is pressurized by the gas compressor 1 and then passed into the gas-liquid separator 2 to remove water, foam and solid particles; the liquid settles in the lower part of the separator and is controlled by the liquid level. The valve 16 discharges; the solid dirt settles at the bottom of the gas-liquid separator 2, and is discharged through the sewage outlet 18; the middle part of the separator is provided with a defoaming plate 19, which is used to eliminate the air bubbles on the gas-liquid interface, so as to facilitate the overflow of gas from the liquid; After the gas passes through the mist catcher 17 to remove small mist droplets, it passes through the pressure control valve 15 into the sodium carbonate solution tank 3 to remove hydrogen sulfide in the landfill gas.

[0031] The landfill gas from which water, foam, solid impurities and hydrogen sulfide have been r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com