Method for preparing supercapacitor-dedicated active carbon by using mixed molten salts as activator

A technology of supercapacitor and mixed molten salt, which is applied in the field of preparing activated carbon for supercapacitors, can solve the problems of increasing the corrosion of activation equipment, which is not conducive to wide application, and affects the application of activated carbon, and achieves low cost, good high-current charge and discharge performance, The effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Using pitch as carbon source, KCl and ZnCl 2 The mixture is mixed molten salt, and activated carbon is prepared by one-step carbonization activation method. First, 35 wt% KCl and 65 wt% ZnCl 2 Mix well, then add asphalt, the ratio of mixing salt and asphalt is 3:1. The homogeneously mixed block material was placed in a tube furnace and heated to 1000 °C for 1 h at a heating rate of 5 °C / min under the protection of Ar gas to obtain a sample. The carbonized sample was pulverized, washed and dried to obtain black activated carbon.

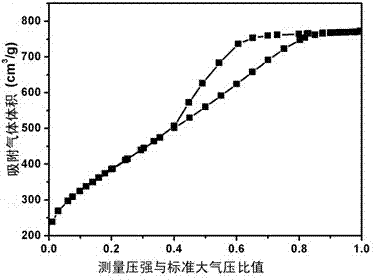

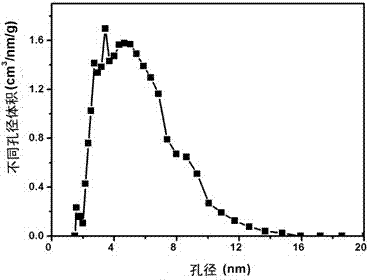

[0028] N 2 Adsorption-desorption curves and pore size distribution curves ( figure 1 and figure 2 ) results show that its specific surface area reaches 1500 m 2 / g, the pore volume reaches 1.19 cm 3 / g, the pore size distribution is in the range of 2.5 nm~16 nm.

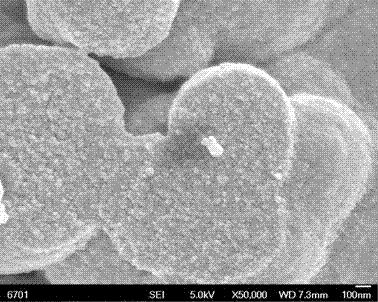

[0029] The results observed under the electron microscope ( image 3 ) shows that the activated carbon prepared under this condition is spherical, and the diameter of the s...

Embodiment 2

[0032] Using pitch as carbon source, KCl and ZnCl 2 The mixture is mixed molten salt, and activated carbon is prepared by one-step carbonization activation method. First, 15 wt% KCl and 85 wt% ZnCl 2 Mix well, then add asphalt, the ratio of mixing salt and asphalt is 6:1. The homogeneously mixed bulk material was placed in a tube furnace and heated to 800 °C for 2 h at a heating rate of 2 °C / min under the protection of Ar gas to obtain a sample. The carbonized sample was pulverized, washed and dried to obtain black activated carbon.

[0033] N 2 The adsorption-desorption curve results show that the specific surface area of activated carbon obtained under this condition is 2000 m 2 / g, with a pore volume of 1.4 cm 3 / g. The pore size of activated carbon materials still remains in the range of 2.5 nm to 16 nm.

[0034] In this example, the specific capacitance of the activated carbon material in the aqueous electrolyte is 240 F / g, and it has good high-current charge-dis...

Embodiment 3

[0036] Using pitch as carbon source, KCl and ZnCl 2 The mixture is mixed molten salt, and activated carbon is prepared by one-step carbonization activation method. First, 25 wt% KCl and 75 wt% ZnCl 2 Mix well, then add asphalt, the ratio of mixing salt and asphalt is 1:1. Put the homogeneously mixed block material in the tube furnace, under N 2 Under gas protection, the sample was obtained by heating to 900 °C for 1.5 h at a heating rate of 10 °C / min. The carbonized sample was pulverized, washed and dried to obtain black activated carbon.

[0037] N 2 The adsorption-desorption curve results show that the specific surface area of activated carbon obtained under this condition is 1000 m 2 / g, with a pore volume of 1.0 cm 3 / g. The pore size of activated carbon materials still remains in the range of 2.5 nm to 16 nm.

[0038]In this example, the specific capacitance of the activated carbon material in the aqueous electrolyte is 160 F / g, and it has good high-current char...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com