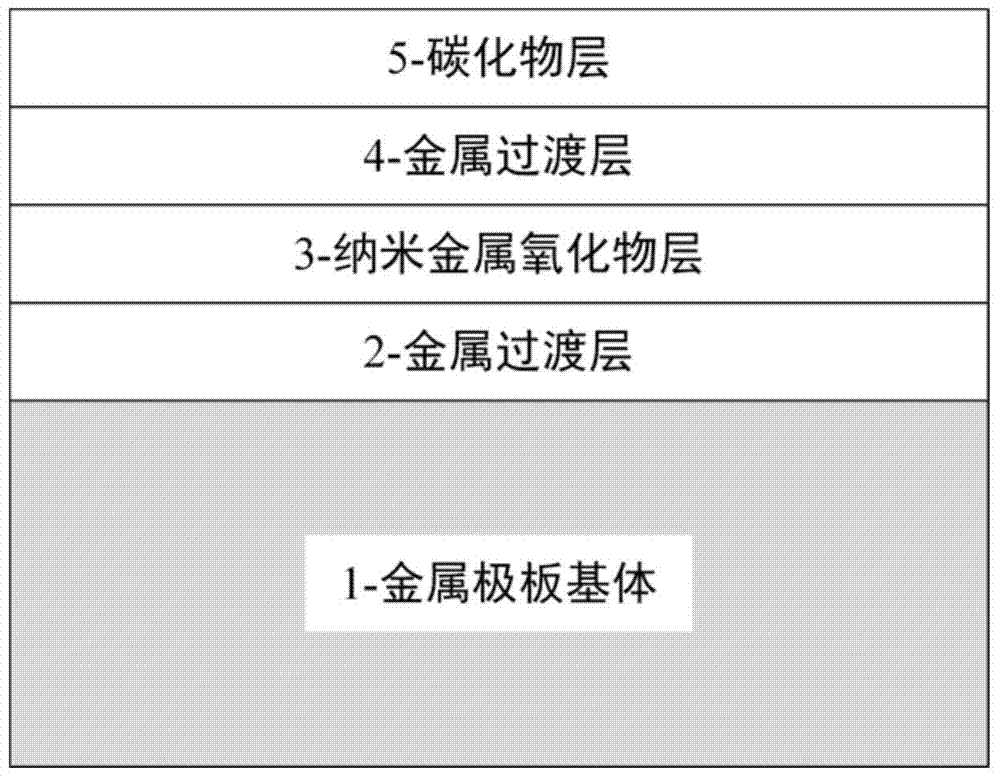

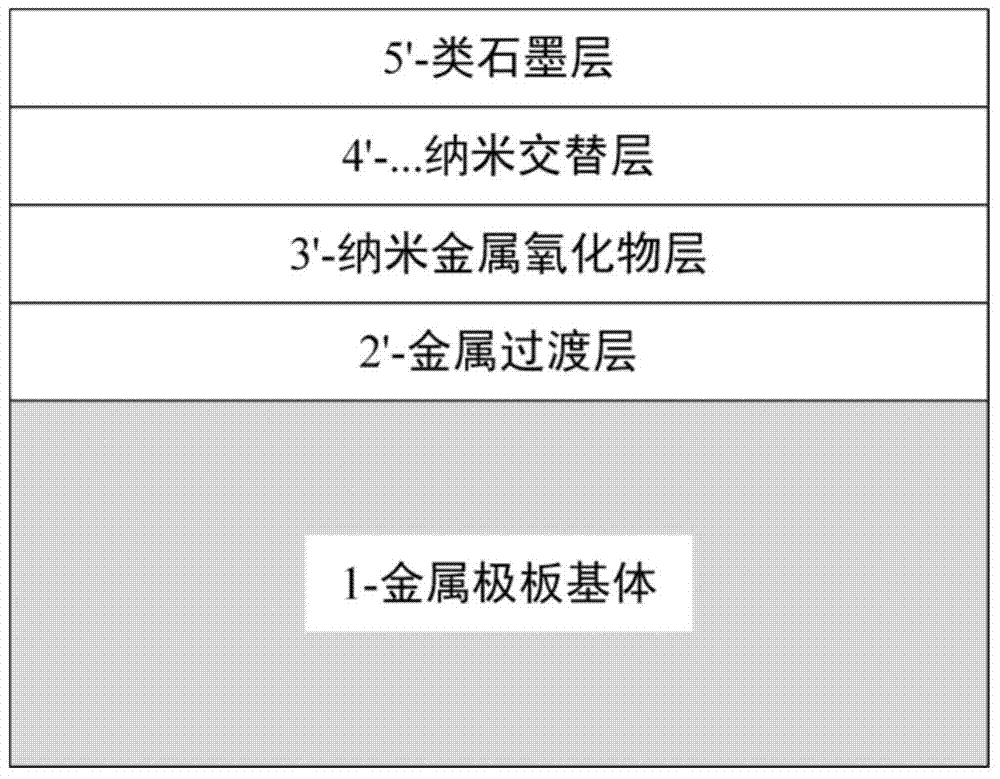

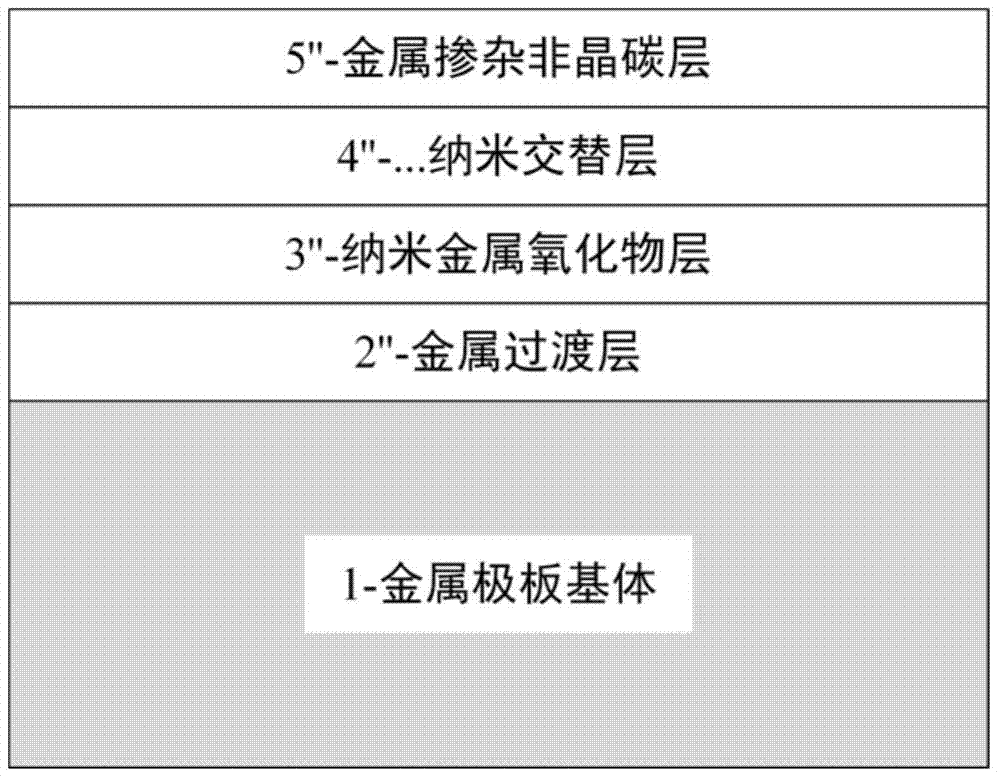

Carbide and metal oxide composite coat for fuel cell metal pole plate, and production method thereof

A technology of metal plates and oxide layers, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of increased physical property differences, flat and low density of the film surface, and reduced corrosion resistance, and achieve enhanced compatibility , Accelerate the development of industrialization and improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of SnO by Unbalanced Magnetron Sputtering Ion Plating Technology 2 :F+GIC:Sn film system

[0031] (1) ultrasonically cleaning the surface of the metal plate substrate 1 with acetone and absolute ethanol in sequence;

[0032] (2) Put the metal plate after ultrasonic cleaning into the unbalanced magnetron sputtering ion plating furnace cavity, and the vacuum is better than 3×10 -5 torr, filled with argon, the working pressure is kept at 4×10 -4 torr, the bias voltage of the substrate is -500V, the passivation layer of the substrate is removed by ion bombardment, the cleaning process time of ion plating and sputtering is 30min, the sample is hung on the rotating bracket, and the rotation speed of the bracket is 4r / min;

[0033] (3) The substrate bias is maintained at -60V, the Sn target current is turned on, the current is gradually increased from 0 to 6A, and the metal transition layer 2 is deposited on the surface of the metal plate substrate 1, and the dep...

Embodiment 2

[0038] Preparation of TiO by Pulse Arc Ion Plating Technology 2 +GIC:Ag film system

[0039] (1) Use acetone and absolute ethanol to ultrasonically clean the surface of the metal plate substrate successively;

[0040] (2) Dry the metal plate substrate after ultrasonic cleaning with a blower and put it on the bracket in the cavity of the multi-family ion plating furnace, and vacuumize it to 8×10 -3 Pa, enter Ar gas, apply negative bias voltage of -700V to trigger glow discharge, and perform Ar ion glow cleaning for 10 minutes;

[0041] (3) Reduce the bias voltage of the metal plate base to -500V, turn on the Ti target current of 70A, and turn on the O 2 , depositing TiO on the surface of the plate 2 To obtain a metal oxide layer, the deposition time is 10 minutes;

[0042] (4) Maintain the substrate bias, close the oxygen flow, maintain the Ti target current, deposit the metal Ti transition layer, and the deposition time is 5 minutes;

[0043] (5) Maintain the substrate bi...

Embodiment 3

[0045] Preparation of ZrO by Chemical Vapor Deposition Technology 2 +ZrC film system

[0046] (1) Use acetone and absolute ethanol to ultrasonically clean the surface of the metal plate substrate successively;

[0047] (2) Dry the metal plate substrate after ultrasonic cleaning and put it into the furnace cavity with a blower, and select Ar as the carrier gas and dilution gas, H 2 As a reducing gas, CO 2 As a carbon source gas, ZnCl 4 As a Zr source, deposit ZrO on the surface of the metal plate substrate 2 layer, the deposition time is 5 minutes. The overall chemical reaction equation is as follows:

[0048] h 2 +CO 2 =CO+H 2 o

[0049] ZrCl 4 +2H 2 O=ZrO 2 +4HCl

[0050] (3) Close the CO 2 Gas source, into CH 4 As a carbon source, Ar was introduced as a carrier gas and a diluent gas at the same time, H 2 As a reducing gas, ZnCl 4 As a Zr source, a ZrC layer is deposited on the surface of the metal plate. The overall chemical reaction equation is as follows:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com