Bactericidal composition

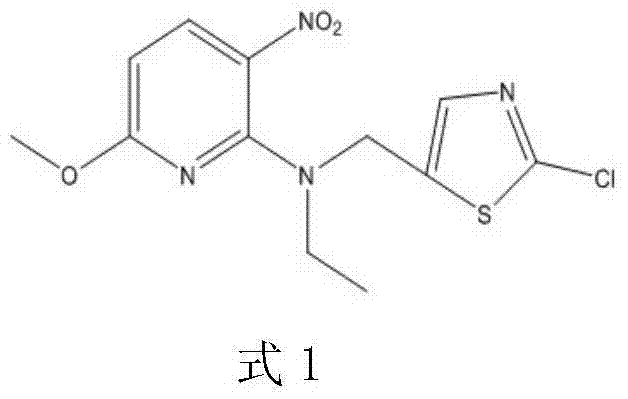

A composition, chlorothalonil technology, applied in the directions of fungicides, biocides, biocides, etc., can solve the problems of unfavorable agricultural sustainable development, pathogen resistance, increased drug dosage, etc., and avoid the occurrence of disease resistance. , the effect of improving drug efficacy and reducing production and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

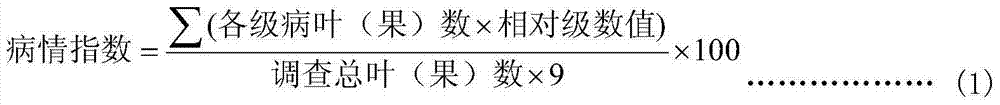

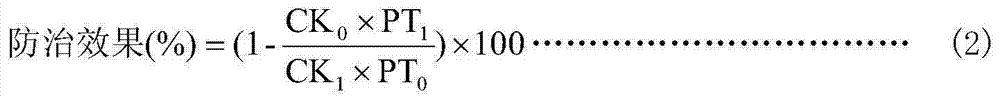

Method used

Image

Examples

Embodiment 1

[0027] Example 1: 50% HNPC-A10073 Chlorothalonil water dispersible granules

[0028] When the present invention is a water-dispersible granule, the weight percentage of each component is: HNPC-A10073 15%; chlorothalonil 35%; dispersant: calcium dodecylbenzenesulfonate 12%; wetting agent: wetting agent Wet penetration agent F 8%; disintegrant: sodium chloride 2%; filler talc 5%; kaolin added to 100%. The specific production steps of the water-dispersible granules are as follows: mix the active ingredient HNPC-Aa10073 with chlorothalonil, dispersant, wetting agent, disintegrating agent and filler uniformly according to the above formula, pulverize with an ultrafine jet mill, knead, Then put it into a fluidized bed granulation dryer for granulation, drying, sieving, and after sampling and analysis, the water-dispersible granule formulation of the composition of the present invention can be prepared.

Embodiment 2

[0029] Example 2: 20% HNPC-A10073 Chlorothalonil Suspension Concentrate

[0030] When the present invention is processed into a suspension, the weight percentage of each component is: HNPC-A10073 7%; chlorothalonil 13%; emulsifier: BY-140 7%, nonylphenol polyoxyethylene ether 8%; solvent : cyclohexanone 6%, methanol 8%; wetting agent: sodium butylnaphthalene sulfonate: 3%; dispersing agent calcium alkylbenzene sulfonate: 3%; antifreeze agent: propylene glycol 1%; thickener: xanthan gum 0.1%; defoamer silicone: 0.1%; deionized water added to 100%. The specific production steps of the suspension are as follows: first mix the above-mentioned components except the active ingredients, and then mix them uniformly through high-speed shearing, then add the active ingredients HNPC-A10073 and chlorothalonil, and grind them in a ball mill for 2- After 3 hours, the particle size of the particles is all below 5 μm, that is, the suspension preparation of the composition of the present inve...

Embodiment 3

[0031] Example 3: 70% HNPC-A10073 Chlorothalonil wettable powder

[0032] When the present invention is a wettable powder, the weight percentage of each component is: HNPC-A10073 20%; chlorothalonil 50%; dispersant: lignosulfonate 8%; wetting agent: pull open powder BX 8% ; Filler: Talc 6%; Kaolin added to 100%. The specific production steps of the wettable powder are as follows: the active ingredient HNPC-A10073 is mixed with chlorothalonil, dispersant, wetting agent and filler, mechanically pulverized, then jet pulverized, and mixed uniformly to produce the composition of the present invention wettable powder formulations. The active ingredient HNPC-A10073 is mixed with chlorothalonil, dispersant, wetting agent and filler, mechanically pulverized and then jet pulverized, and mixed uniformly to prepare the wettable powder preparation of the composition of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com