Trifluralin micro-capsule granule and preparation method thereof

A technology of microencapsulated granules and trifluralin, which is applied in the fields of botanical equipment and methods, biocides, biocides, etc., can solve the problems that affect the promotion and application of preparations, easily cause phytotoxicity, and have a short duration of effect, etc. To avoid the problem of pesticide damage, reduce the number of spraying, and reduce the effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

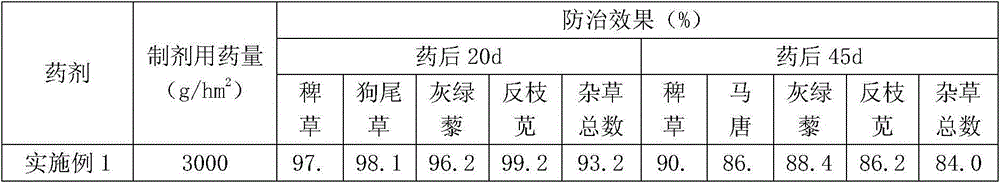

Examples

Embodiment 1

[0021] Embodiment 1: Preparation of Trifluralin Microcapsules

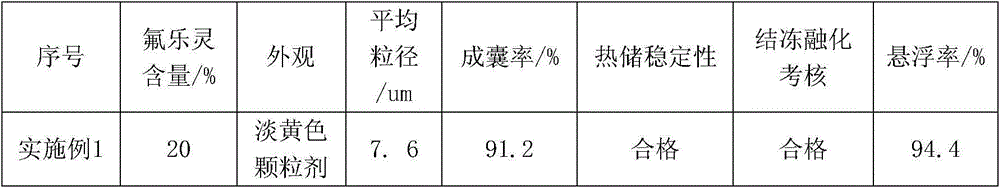

[0022] Table 1 - Raw material formula of trifluralin microcapsules

[0023] components

[0024] Xylene

[0025] Dissolve 12g of trifluralin and 1g of 2-hydroxy-4-methoxybenzophenone in 15g of xylene at room temperature, add 3g of styrene-maleic anhydride copolymer sodium salt, 2g of triphenylethyl Base phenol polyoxyethylene polyoxypropylene ether, 3g sodium dodecylbenzenesulfonate, 1g xanthan gum and 20g urea-formaldehyde resin prepolymer, make up to 100g with deionized water, and react with high-speed stirring at 1500 rpm for 1h. After the oil-in-water emulsion is formed, reduce the rotation speed to 800 rpm, and add ammonium chloride solution in 6 batches within 1 hour to adjust the pH of the system to 3.0. After 1 hour of polymerization, gradually raise the temperature to 60°C to solidify the capsule wall for 2 hours. Add sodium hydroxide to adjust the pH to 7.0, add 3.0g sodium lignosulfo...

Embodiment 2

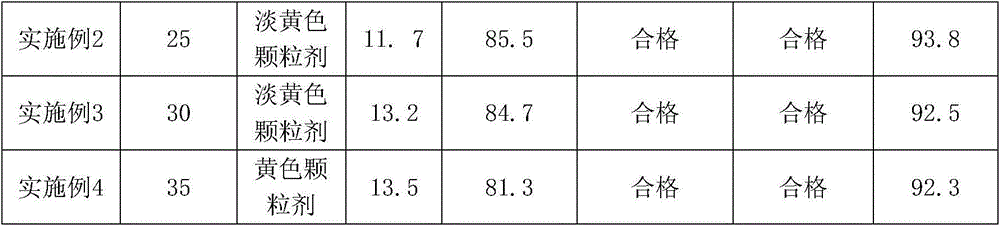

[0026] Embodiment 2: the preparation of trifluralin microcapsules

[0027] Table 2- Raw material formula of trifluralin microcapsule granules

[0028] components

[0029] Dissolve 18g of trifluralin and 1g of 2,4-dihydroxybenzophenone in 20g of xylene at room temperature, add 2.5g of styrene-maleic anhydride copolymer sodium salt, 2g of alkylphenol polyoxygen Ethylene polyether and its sulfate, 1.5g sodium dodecylbenzenesulfonate, 0.3g polyvinyl alcohol and 24g urea-formaldehyde resin prepolymer aqueous solution, supplemented with deionized water to 100g, stirred and reacted at a high speed of 1500 rpm for 1h, and waited After the oil-in-water emulsion is formed, reduce the rotation speed to 800 rpm, and add ammonium chloride solution in 6 batches within 1 hour to adjust the pH of the system to 3.0. After 1 hour of polymerization, gradually raise the temperature to 60°C to solidify the capsule wall for 2 hours. Add sodium hydroxide to adjust the pH to 7.0, add 3.0g ...

Embodiment 3

[0030] Embodiment 3: Preparation of trifluralin microcapsules

[0031] Table 3- Raw material formula of trifluralin microcapsules

[0032] components

[0033] Deionized water

[0034] Dissolve 24g of trifluralin, 0.8g of 2-hydroxy-4-methoxybenzophenone, and 0.2g of phenyl o-hydroxybenzoate in 25g of xylene at room temperature, and add 4g of styrene- Maleic anhydride copolymerized sodium salt, 2g triphenylethylphenol polyoxyethylene polyoxyethylene ether, 3g sodium dodecylbenzenesulfonate, 0.2g gum arabic and 28g urea-formaldehyde resin prepolymer, deionized water added to 100g, Stir and react at a high speed of 1500 rpm for 1 hour. After the oil-in-water emulsion is formed, reduce the speed to 800 rpm. Add ammonium chloride solution in 6 batches within 1 hour to adjust the pH of the system to 3.0. After 1 hour of polymerization, Gradually raise the temperature to 60°C to solidify the capsule wall for 2 hours, then add sodium hydroxide to adjust the pH to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com