Nano composite coating and deposition method thereof

A nano-composite coating and coating technology, which is applied in the coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of coating shedding, affecting the service life of the coating, and difficult control of metal stress. Extended service life, high hardness, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

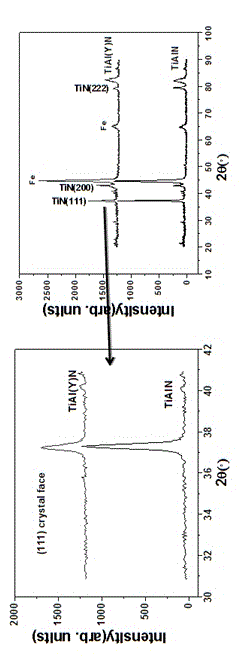

Image

Examples

Embodiment 1

[0025] A kind of preparation of composite coating, according to the following steps:

[0026] Prepare metal-ceramic tools (TiCN) for sandblasting, then ultrasonically clean them in demineralized water, acetone, and absolute ethanol for 5 minutes, and put them into a vacuum chamber after drying. Evacuate the air pressure of the vacuum chamber of the equipment to 3.0×10 -3 After Pa, argon gas was introduced for scrubbing. After 30 minutes, the gas pressure in the vacuum chamber was adjusted to 4Pa, and the target baffle was kept closed; a pulse voltage of 800V (40KHz) was applied to the workpiece for plasma etching and cleaning for 30 minutes. After completion, adjust the gas pressure to 3×10 -1 Pa, open the target baffle, and perform pre-sputtering on the Ti target, TiAlY target and Si target respectively to remove the pollutants on the target surface. After cleaning, keep the gas pressure 3×10 -1 Pa, use a DC sputtering power supply, adjust the power supply current to 0.4A...

Embodiment 2

[0028] A kind of preparation of composite coating, according to the following steps:

[0029] Prepare the high-speed steel tool for sandblasting, then ultrasonically clean it in demineralized water, acetone, and absolute ethanol for 10 minutes, and put it into a vacuum chamber after drying. Evacuate the air pressure of the vacuum chamber of the equipment to 3.0×10 -3 Below Pa, argon gas is passed through for scrubbing. After 30 minutes, the gas pressure in the vacuum chamber was adjusted to 4Pa, and the target baffle was kept closed; a pulse voltage of 800V (40KHz) was applied to the workpiece, and plasma etching was performed for 30 minutes. After completion, adjust the gas pressure to 3×10 -1 Pa, open the target baffle, and perform pre-sputtering on the Cr target, TiAlY target and Si target respectively to remove the pollutants on the target surface. After cleaning, keep the gas pressure 3×10 -1 Pa, using a DC sputtering power supply, adjusting the power supply current t...

Embodiment 3

[0031] A kind of preparation of composite coating is carried out as follows:

[0032] (1) Pretreatment: Sandblast the finely ground hard alloy tool, then ultrasonically clean it in absolute ethanol and demineralized water, and put it into the vacuum chamber of the coating equipment after drying.

[0033] (2) Gas washing: pump the vacuum chamber pressure of the coating equipment to 5.0×10 -3 After Pa, nitrogen and argon are passed into the vacuum chamber to perform gas washing; the flow of the nitrogen is 30 sccm (standard milliliters / minute), and the flow of the argon is 60 sccm; while the vacuum chamber temperature is heated to 400 ℃ Coating operating temperature.

[0034] (3) Etching and cleaning: After heating, adjust the argon pressure in the vacuum chamber of the coating equipment to about 4.0Pa, apply a pulse bias voltage of 800V on the sample stage for 30 minutes; perform plasma etching and cleaning on the cutting tool to be plated.

[0035] (4) film layer preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com