Flexible graphene current collector and active material integrated electrode pole piece and preparation method thereof

An electrode pole piece, flexible graphite technology, applied in battery electrodes, electrode carriers/current collectors, non-aqueous electrolyte battery electrodes, etc., can solve battery performance rate performance limitations, increase active material adhesion, limit battery energy density, etc. problems, to achieve great application value, improve cycle life and safety, and enhance the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

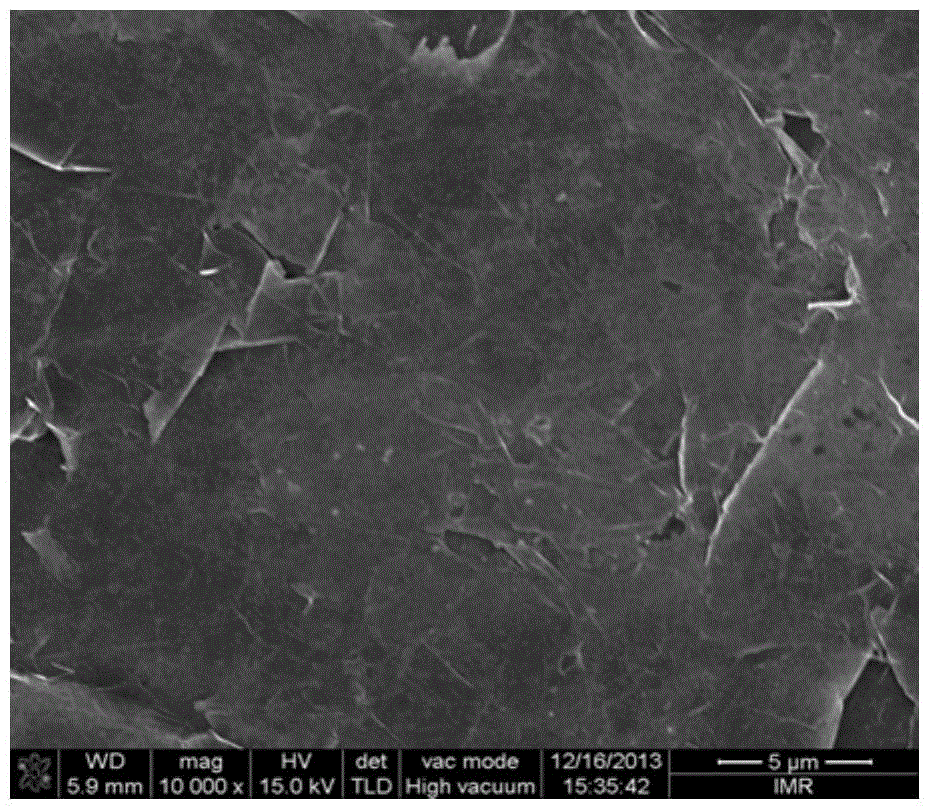

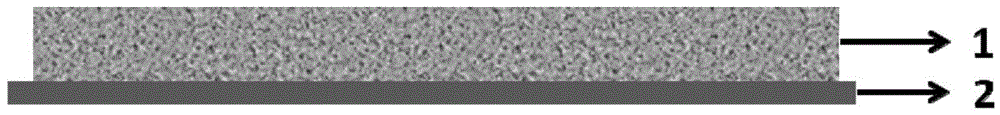

[0035] The embodiment of the present invention also provides a method for preparing an electrode sheet integrated with a flexible graphene current collector and an active material for a lithium battery, which also includes a method for preparing a graphene current collector layer. The preparation method of the graphene current collector layer comprises: mixing graphene with a solvent, and dispersing to form a uniform and stable solution. The solvent is preferably one or more of water, ethanol, acetone or N-methylpyrrolidone. The amount of solvent added will affect the dispersion effect of graphene in it, so it should not be too small, so the mass ratio of graphene:solvent=1:(1-20) is preferred. In order to obtain a more fine and uniform graphene solution, the dispersion strength can be properly enhanced and the dispersion time can be prolonged. Since the graphene current collector layer in the present invention is prepared by vacuum filtration, all solvents can be recovered a...

Embodiment 1

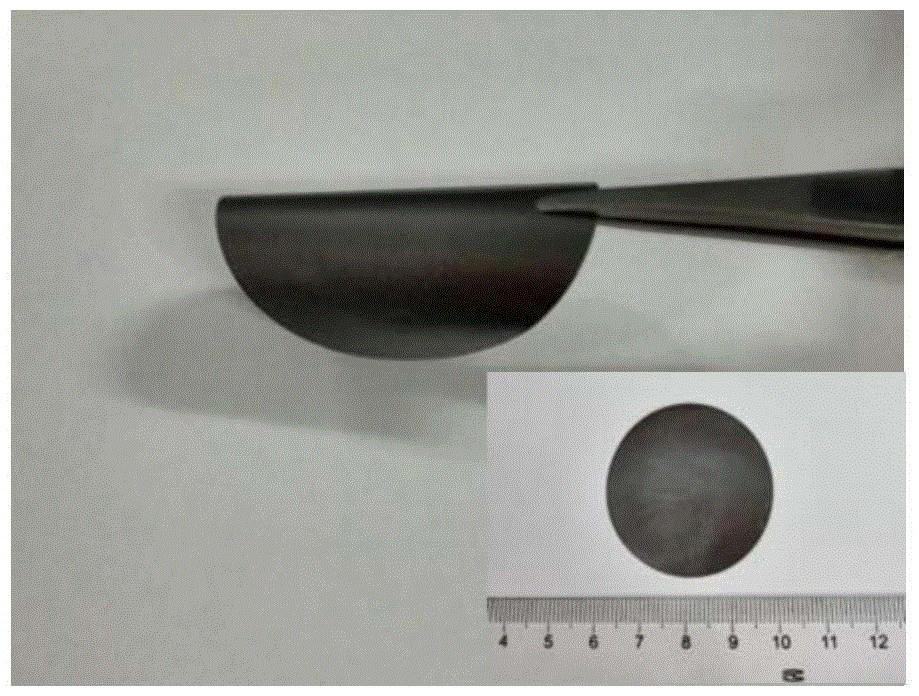

[0044] Weigh 20 mg of graphene powder and add it to 50 mL of N-methylpyrrolidone, ultrasonically disperse for 0.5 h to obtain a uniform graphene solution, and suction filter the graphene solution into a polyvinylidene fluoride filter membrane with a pore size of 0.45 μm and a diameter of 50 mm Above, the graphene current collector layer is obtained; the commercialized lithium titanate powder, conductive carbon black, and binder PVDF are stirred and mixed in the solvent NMP according to the mass ratio of 8:1:1 to make a uniform active electrode slurry Pour the slurry on the graphene current collector layer and continue suction filtration. After the solvent is exhausted, put it together with the filter membrane in a 60°C oven for drying. After drying, it is peeled off from the filter membrane and rolled. Obtain the graphene current collector-lithium titanate negative pole sheet, such as Figure 4 shown.

[0045] The electrode pole pieces prepared above were cut and assembled in...

Embodiment 2

[0052] Weigh 20 mg of graphene powder and add it to 80 mL of N-methylpyrrolidone, ultrasonically disperse for 0.5 h to obtain a uniform graphene solution, and suction filter the graphene solution into a polyvinylidene fluoride filter membrane with a pore size of 0.22 μm and a diameter of 50 mm Above, the graphene current collector layer is obtained; the commercialized lithium iron phosphate powder, conductive carbon black, and binder PVDF are stirred and mixed in the solvent NMP according to the mass ratio of 8:1:1 to make a uniform active electrode slurry Pour the slurry on the graphene current collector layer and continue suction filtration. After the solvent is exhausted, put it together with the filter membrane in a 60°C oven for drying. After drying, it is peeled off from the filter membrane and rolled. A graphene current collector-lithium iron phosphate positive electrode sheet is obtained.

[0053] The electrode pole pieces prepared above were cut and assembled into but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com