Sludge dewatering performance improvement method of boron-doped diamond electrode coupled calcium chloride

A diamond electrode and sludge dehydration technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of not being able to satisfy a large amount of sludge removal, poor dehydration performance, and high capillary water absorption of sludge, and improve sludge treatment. Efficiency, improvement of dehydration performance, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

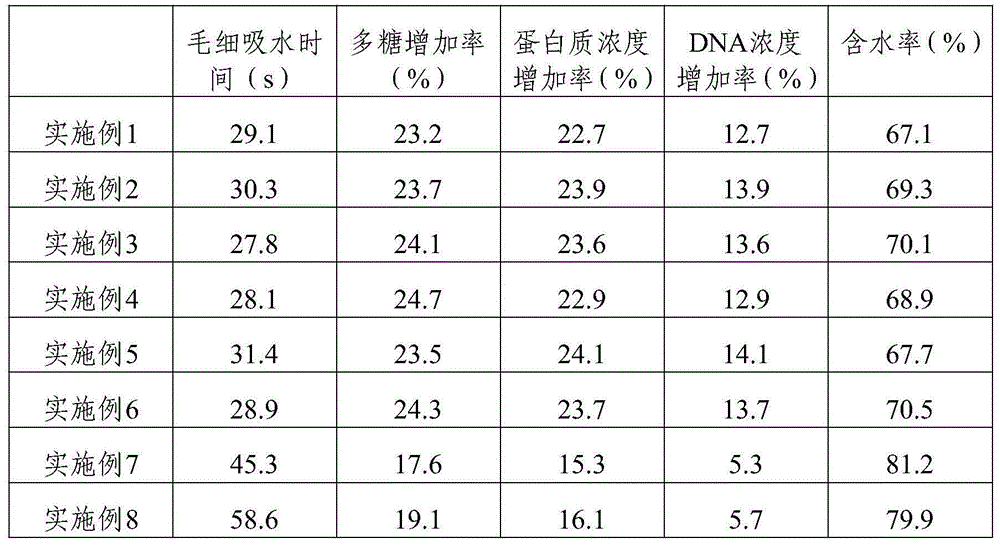

Embodiment 1

[0022] A method for improving sludge dewatering performance by coupling a boron-doped diamond electrode with calcium chloride, using a titanium-based boron-doped diamond electrode as the anode and a stainless steel plate as the cathode; placing it in a cylindrical vessel made of plexiglass, and setting the anode electrode and The distance between the cathode electrodes is 3m, and the voltage is 15V to form an electrolytic cell, coupled with calcium chloride treatment, and centrifugal dehydrator for dehydration.

[0023] Specifically: collect untreated sludge, check the pH, and when the sludge is alkaline, add a pH regulator with a molar concentration of 0.1mol / L to the sludge to adjust the pH to 5.5; then use titanium-based boron The doped diamond electrode is used as the anode, and the stainless steel plate is used as the cathode; and the distance between the anode electrode and the cathode electrode is set to 3cm, the voltage is 15V, and the stirring speed is 50r / min for 15mi...

Embodiment 2

[0026] A method for improving sludge dewatering performance by coupling a boron-doped diamond electrode with calcium chloride, using a titanium-based boron-doped diamond electrode as the anode and a stainless steel plate as the cathode; placing it in a cylindrical vessel made of plexiglass, and setting the anode electrode and The distance between the cathode electrodes is 5cm, and the voltage is 21V to form an electrolytic cell, coupled with calcium chloride treatment, and centrifugal dehydrator for dehydration.

[0027]Specifically: collect the sludge that has not been dehydrated, check the pH, and when the sludge is acidic, add a pH regulator with a molar concentration of 1mol / L to the sludge to adjust the pH to 7; then use titanium-based boron doping The diamond electrode is used as the anode, and the stainless steel plate is used as the cathode; and the distance between the anode electrode and the cathode electrode is set to 5cm, the voltage is 21V, and the stirring speed i...

Embodiment 3

[0030] A method for improving sludge dewatering performance by coupling a boron-doped diamond electrode with calcium chloride, using a titanium-based boron-doped diamond electrode as the anode and a stainless steel plate as the cathode; placing it in a cylindrical vessel made of plexiglass, and setting the anode electrode and The distance between the cathode electrodes is 4cm, and the voltage is 20V to form an electrolytic cell, coupled with calcium chloride treatment, and centrifugal dehydrator for dehydration.

[0031] Specifically: collect the sludge that has not been dehydrated, check the pH, and when the sludge is acidic, add a pH regulator with a molar concentration of 0.9mol / L to the sludge to adjust the pH to 6.7; then use titanium-based boron doping The mixed diamond electrode is used as the anode and the stainless steel plate is used as the cathode; and the distance between the anode electrode and the cathode electrode is set to 4cm, the voltage is 20V, and the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com