Organic silicon waste contact body borne nickel-based methanation catalyst and preparation method therefor

A technology of organosilicon waste contact body and methanation catalyst is applied in the field of nickel-based methanation catalyst supported by organosilicon waste contact body and its preparation field, which can solve the problems of added value of secondary pollution products, complicated treatment process, etc. The effect of resisting carbon deposition, inhibiting agglomeration and sintering, and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Pretreatment of silicone waste contacts:

[0078] 1) Place the organic silicon waste body in a muffle furnace, calcinate at 300°C for 5 hours, then crush and sieve the samples with a particle size of 0.5-100 μm for use;

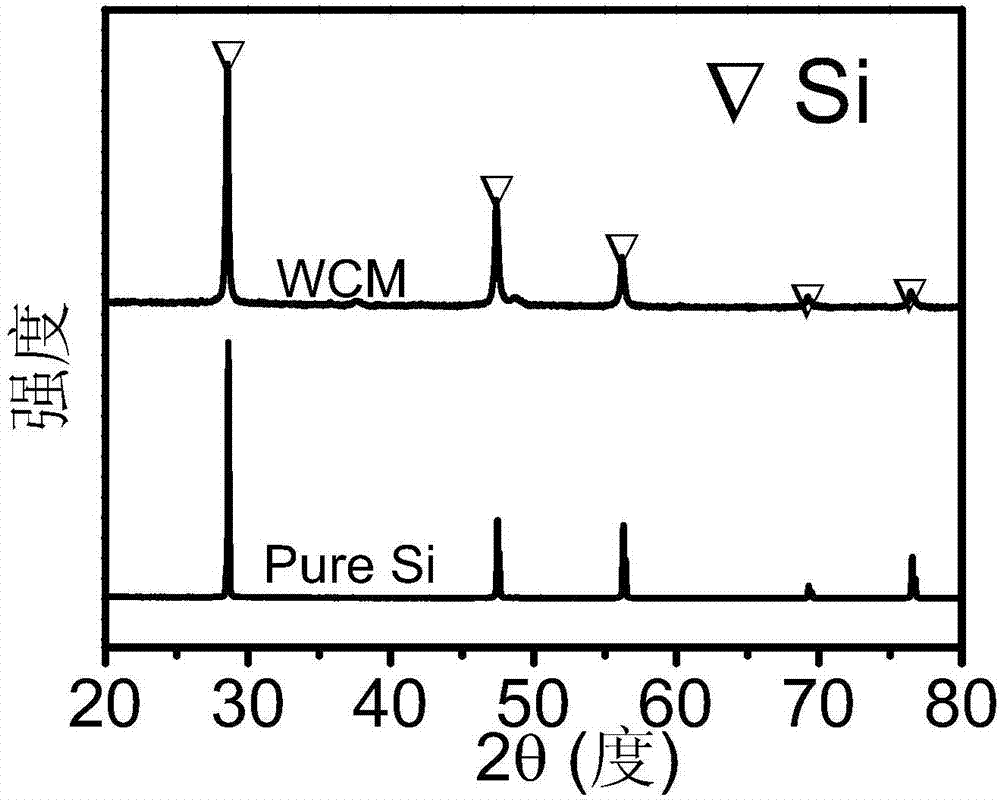

[0079] 2) Put 10 g of the sieved organic silicon waste contact body in a beaker, add 30 mL of 2mol / L nitric acid, put it on a magnetic stirrer, stir at 20°C for 12 hours, pour the supernatant into a waste liquid bottle, After that, wash repeatedly with water until the washing solution is neutral, then filter, and dry the obtained sample in an oven at 100°C for 24 hours; put the dried sample on a ball mill for 12 hours, and the obtained silicon waste contact body is named WCM, and stored for future use.

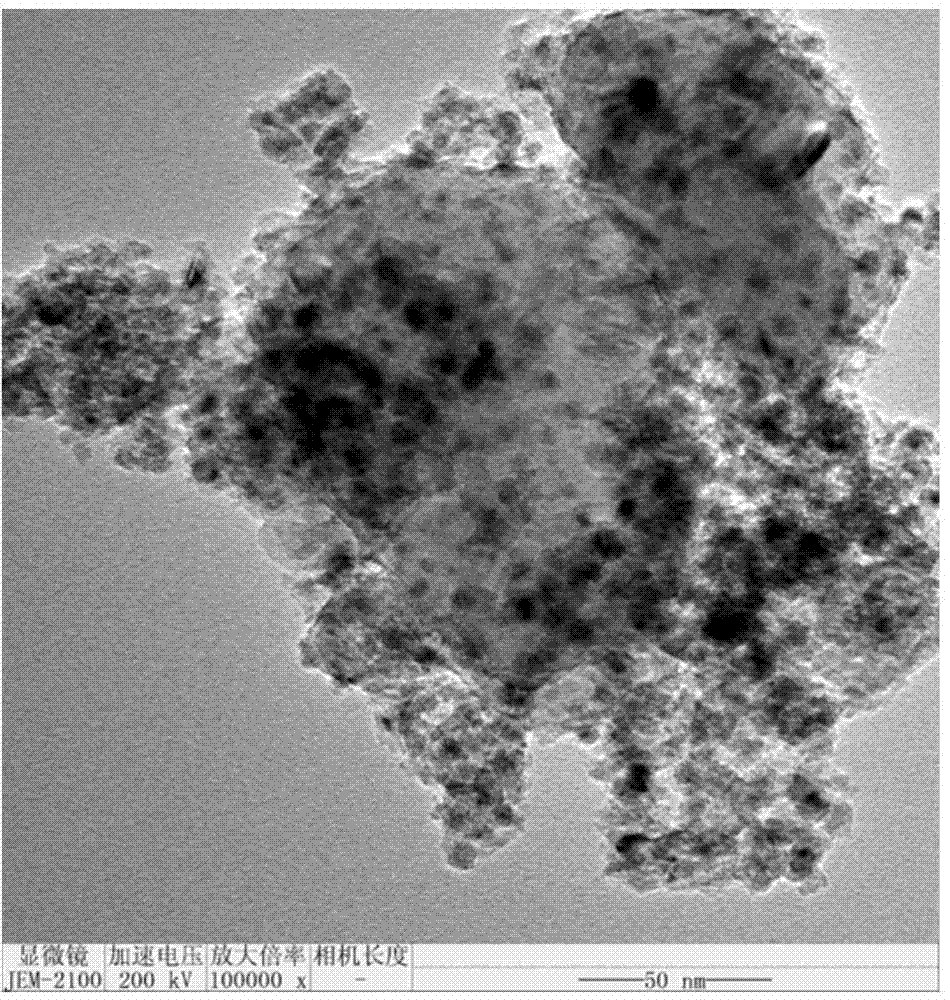

[0080] Catalyst preparation: 3.20g WCM was placed in a round-bottomed flask of 50mL deionized water, stirred rapidly in a water bath at 60°C for 0.5h, and 3.10g Ni(NO 3 ) 2·6H 2 O, 0.21g La(NO 3 ) 3 ·6H 2 O was dissolved in 50mL water respectivel...

Embodiment 2

[0090] Pretreatment of the waste organosilicon contact body: the same treatment steps as in Example 1, except that the calcination temperature of the pretreated silicon waste contact body was changed to 400° C., and the acid used was replaced by HCl.

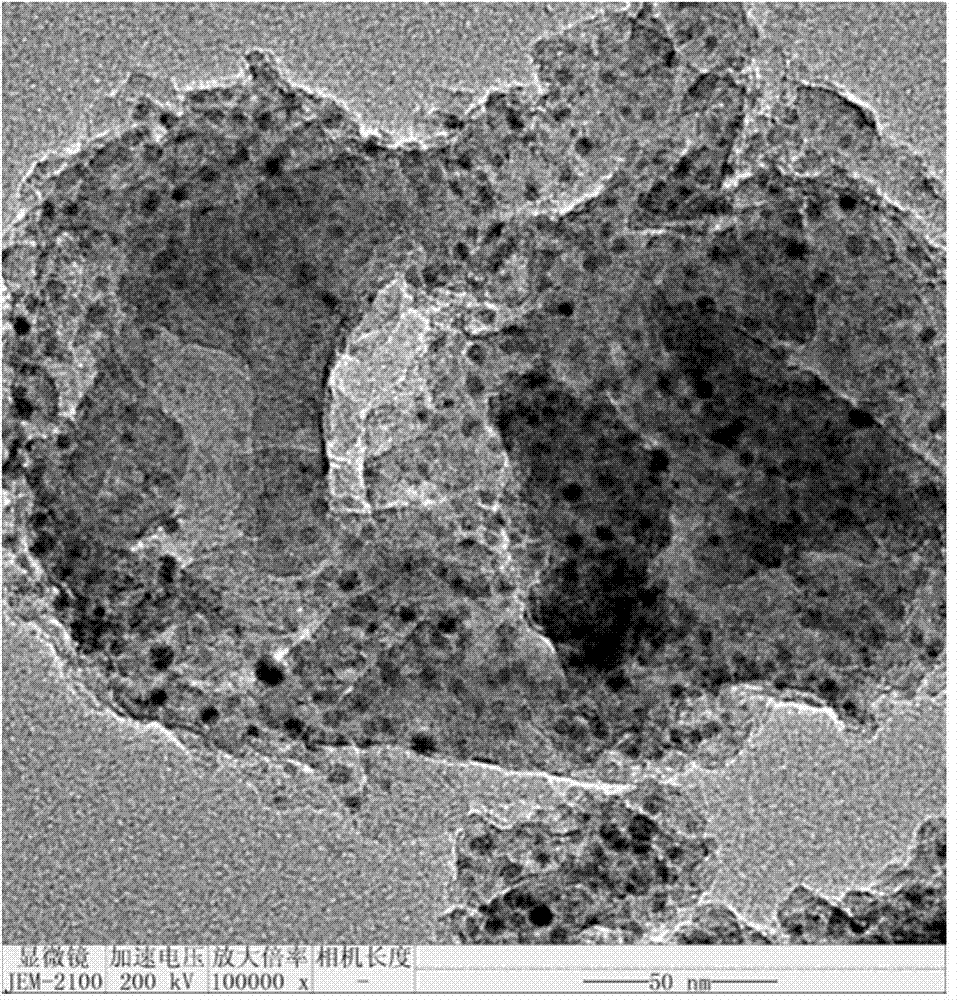

[0091] Catalyst preparation: 2.72g WCM was placed in a round-bottomed flask of 50mL deionized water, stirred rapidly in a water bath at 40°C for 0.5h, and 3.10g Ni(NO 3 ) 2 ·6H 2 O, 2.94g Al(NO 3 ) 3 9H 2 O, 0.33g 50wt% Mn(NO 3 ) 2 Dissolve in 50g of water respectively, and prepare 0.2mol / L NaOH solution, then add the above 4 kinds of solutions into the round bottom flask in parallel, use a pH meter to detect the pH value during the dropping process, and control the pH at about 9 After stirring in a water bath at 40°C for 8h, the sample was filtered and washed until the pH was about 7, and the obtained sample was dried at 100°C for 12h. The obtained samples were calcined at 500 °C for 4 h in an air atmosphere with a heati...

Embodiment 3

[0094] Pretreatment of the waste organosilicon contact body: the same treatment steps as in Example 1, except that the calcination temperature of the pretreated organosilicon waste contact body was changed to 700° C., and the acid used was replaced by sulfuric acid.

[0095] Catalyst preparation: 2.72g WCM was placed in a round bottom flask with 50mL deionized water, stirred rapidly in a water bath at 90°C for 0.5h, and 3.10g Ni(NO 3 ) 2 ·6H 2 O, 2.55g Mg(NO 3 ) 2 ·6H 2 O, 0.2gCe(NO 3 ) 3 ·6H 2 Dissolve O in 50g of water respectively, and configure 0.2mol / L KOH solution, then add the above four kinds of solutions into the round-bottomed flask in parallel, use a pH meter to detect the pH value during the dropping process, and control the pH at about 8 After stirring in a water bath at 90° C. for 8 hours, it was filtered and washed until the pH was about 7, and the obtained sample was dried at 100° C. for 12 hours. The obtained sample was calcined at 700°C for 2 hours in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com