Method for producing protein feed raw materials by carrying out enzymolysis and fermentation on soybean meal

A protein feed and raw material technology, applied in animal feed, animal feed, application, etc., can solve the problems of incomplete decomposition of anti-nutritional factors, mechanization, low scale, high production cost, etc., to shorten the fermentation cycle and improve immunity , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

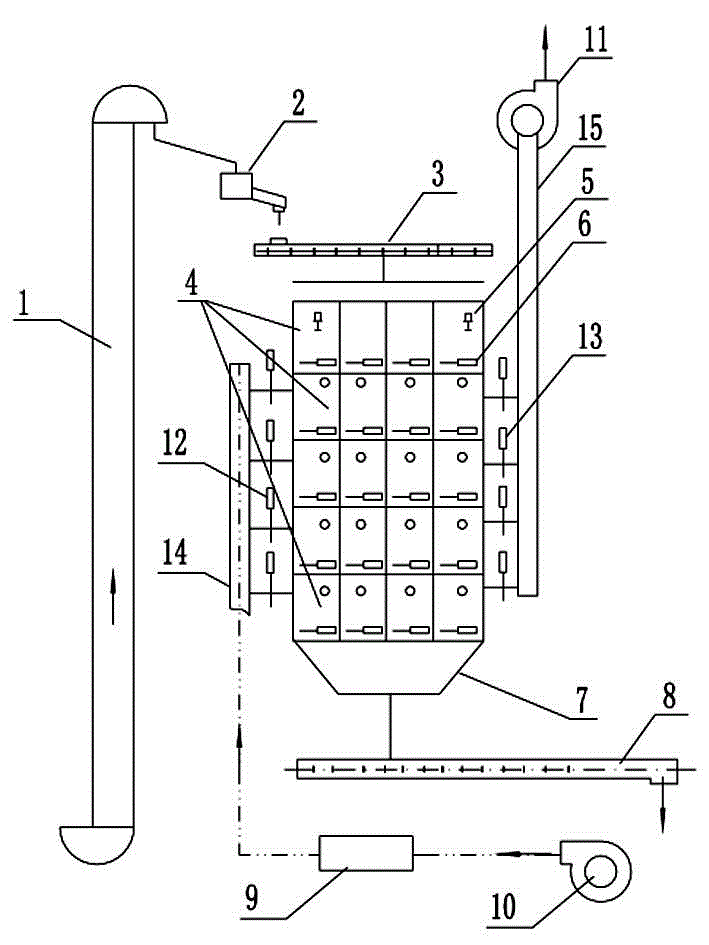

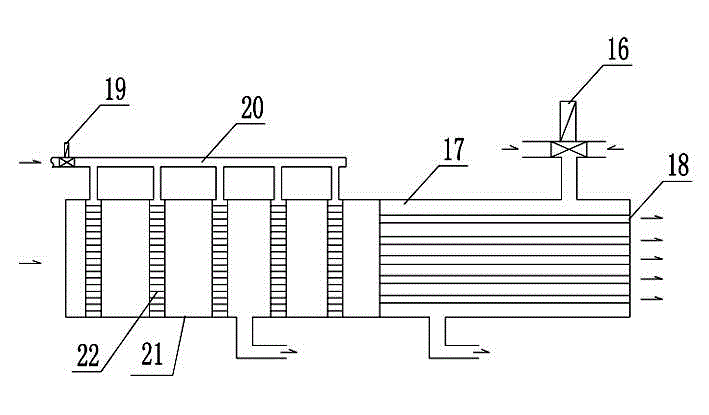

Image

Examples

Embodiment 1

[0052] The method for producing protein feed material by enzymolysis and fermentation of soybean meal according to the present invention comprises the following steps:

[0053] The first step, liquid fermentation

[0054] The specific preparation method of Candida utilis fermented liquid, Bacillus subtilis fermented liquid, Lactobacillus acidophilus fermented liquid is the same as described in the specific embodiment, and it is standby to make mixed bacterial liquid by the ratio of 1:1:1;

[0055] The second step, solid enzymatic hydrolysis and fermentation

[0056] a. Put the soybean meal raw material into the explosion cylinder, the filling coefficient is 60~80%, the explosion cylinder tank is sealed and then filled with 200 ℃ saturated steam, when the pressure of the explosion cylinder reaches 1.0 MPa, keep it for 5 minutes, and open it within 0.00875s Pneumatic valves for steam explosion;

[0057] b. Mix the material after gas explosion, the mixed bacterial liquid pre...

Embodiment 2

[0064] The method for producing protein feed material by enzymolysis and fermentation of soybean meal according to the present invention comprises the following steps:

[0065] The first step, liquid fermentation

[0066] The specific preparation method of Candida utilis fermented liquid, Bacillus subtilis fermented liquid, Lactobacillus acidophilus fermented liquid is the same as described in the specific embodiment, and it is standby to make mixed bacterial liquid by the ratio of 2:1:1;

[0067] The second step, solid enzymatic hydrolysis and fermentation

[0068] a. Put the raw material of soybean meal into the explosion cylinder, the filling coefficient is 60~80%, and the explosion cylinder tank is sealed and then filled with saturated steam at 215°C. When the pressure of the explosion cylinder reaches 1.5Mpa, keep it for 2 minutes, and immediately open the pneumatic valve for steam blasting;

[0069] b. Mix the gas-exploded material, the mixed bacterial solution prep...

Embodiment 3

[0076] The method for producing protein feed material by enzymolysis and fermentation of soybean meal according to the present invention comprises the following steps:

[0077] The first step, liquid fermentation

[0078] The specific preparation method of Candida utilis fermented liquid, Bacillus subtilis fermented liquid, Lactobacillus acidophilus fermented liquid is the same as described in the specific embodiment, and it is standby to make mixed bacterial liquid by the ratio of 2:2:1;

[0079] The second step, solid enzymatic hydrolysis and fermentation

[0080] a. Put the soybean meal raw material into the detonation tank, the filling coefficient is 60~80%, and the tank body of the detonation cylinder is sealed and filled with saturated steam at 250°C. When the pressure of the detonation cylinder reaches 2.0 Mpa, keep it for 0.5 min, and immediately open the pneumatic valve to carry out steam explosion;

[0081] b. Mix the gas-exploded material, the mixed bacterial sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com