Pesticide composition for preventing and treating striped flea beetles

A technology of pesticide composition and flea flea beetle, applied in animal repellents, plant growth regulators, botanical equipment and methods, etc., can solve the problems of pesticide residues, environmental pollution, pest resistance, etc., and achieve prevention and control Long effective time, good environmental compatibility, and improved efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

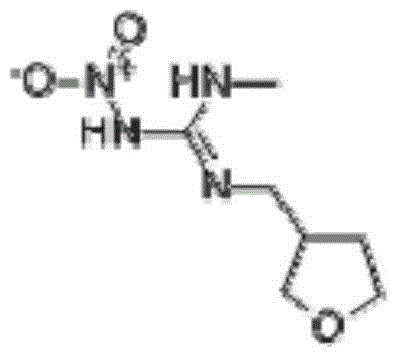

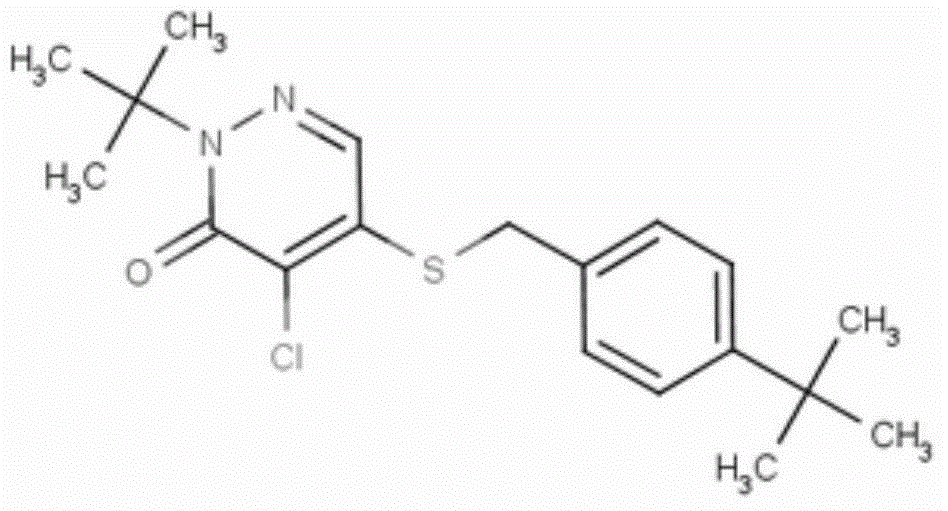

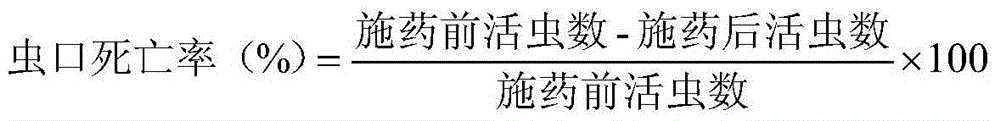

Method used

Image

Examples

Embodiment 1

[0093] Embodiment 1: (40% dinotefuran · pyridaben aqueous suspension concentrate)

[0094] Components and content: dinotefuran, 10%; pyridaben, 30%; emulsifier Nongru NP-10, 1%; dispersant polycarboxylate, 3%; thickeners choose xanthan gum and silicic acid Magnesium aluminum, the dosage is 0.05% and 1% respectively; antifreeze agent ethylene glycol, 3%; antifoaming agent silicone compound, 0.2%; water, balance.

[0095] The preparation method of the above example 1 is as follows: according to the components and weight percentages provided in the examples, dinotefuran, pyridaben, surfactants and other functional additives are placed in the reaction kettle in sequence, and water is added to mix evenly. After high-speed shearing, wet sanding, and finally homogeneous filtration, the water-suspending agent can be obtained. The main equipment is batching kettle, colloid mill or homogeneous mixer, sand mill.

Embodiment 2

[0096] Embodiment 2: (35% dinotefuran · pyridaben water dispersible granule)

[0097] Components and content: dinotefuran, 10%; pyridaben, 25%; wetting agent sodium lauryl sulfate, 4%; dispersant, alkylnaphthalene sulfonate formaldehyde condensate, 7%; disintegrant Ammonium sulfate, 20%; filler attapulgite, balance.

[0098] The preparation method of the above-mentioned Example 2 is: according to the components and their weight percentages provided in the examples, dinotefuran, pyridaben, dispersant, wetting agent and filler are mixed evenly, and after being pulverized by a jet mill, add 10- 25% water, then kneading, extrusion granulation, and drying to obtain water-dispersible granules. Or spray the pulverized powder with water in a boiling granulator, granulate, dry, and then sieve to obtain water-dispersible granules. The main equipments are mixer, jet mill, kneader, extrusion granulator, drying room or fluidized bed drying, or boiling granulator, screening machine.

Embodiment 3

[0099] Embodiment 3: (18% dinotefuran · pyridaben aqueous emulsion)

[0100] Components and content: dinotefuran, 4%; pyridaben, 14%; emulsifier Nongru BY-125, 3%; emulsifier nonylphenol polyoxyethylene ether phosphate 3%; solvent selection cyclohexanone and Xylene, consumption is 8% and 20% respectively, antifreeze is selected propylene glycol, consumption 4%, water, balance.

[0101] The preparation method of the above-mentioned Example 3 is: according to the components and weight percentages provided in the examples, add dinotefuran, pyridaben, emulsifier, and solvent into the mixing tank, stir until completely dissolved, and set aside; add propylene glycol and Add water into the shearing kettle, turn on the shearing equipment, slowly add the dissolved dinotefuran pyridaben solution into the shearing kettle dropwise, and continue shearing for half an hour after the dropping to obtain the aqueous emulsion. The main equipment is mixing kettle and shearing kettle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com