Preparation method of nitrogen-doped carbon quantum dot and titanium dioxide composite material

A technology of carbon quantum dots and titanium dioxide, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of low photon quantum efficiency, hydrogen gas has not been reported, etc., achieve broad application prospects, excellent photocatalytic methanol The performance of decomposing hydrogen production and the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

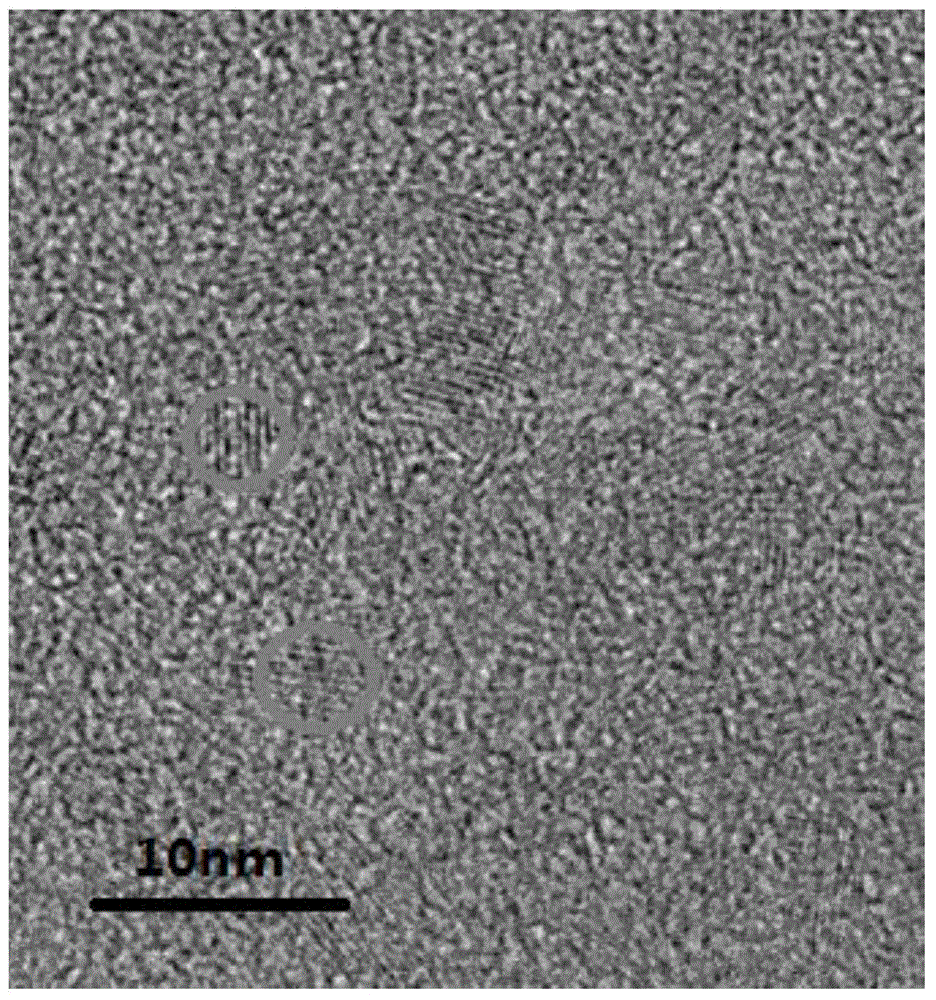

[0037] At room temperature, put 2g of glucose and 80ml of acetonitrile into the inner tank of a polytetrafluoroethylene hydrothermal kettle for a hydrothermal reaction (reaction condition is 180°C, 10h); after the reaction kettle is cooled to room temperature, the product is suction filtered, and the filtrate is collected. Wash the filtrate repeatedly with dichloromethane; use a rotary evaporator to evaporate the filtrate at 65°C, and after concentration, use a dialysis bag with a molecular weight cut-off of 100 to dialyze for two weeks; use the rotary evaporator again to concentrate the product at 80°C , And then freeze-drying (-45℃, 48h) to obtain brown powder as nitrogen-doped carbon quantum dots; the obtained nitrogen-doped carbon quantum dots and titanium dioxide are respectively 5:95, 10:90, 15:85 and 20:80 The mass ratio is mixed, and then placed in an oven at 80°C for aging. The material is then dried and put into a methanol solution with a mass fraction of 5% to cataly...

Embodiment 2

[0039] At room temperature, 10g glucose and 80ml acetonitrile are put into the inner tank of a polytetrafluoroethylene hydrothermal kettle for hydrothermal reaction (reaction conditions are 160°C, 14h); after the reaction kettle is cooled to room temperature, the product is suction filtered, and the filtrate is collected. Wash the filtrate repeatedly with dichloromethane; use a rotary evaporator to evaporate the filtrate at 80°C, and after concentration, use a dialysis bag with a cut-off molecular weight of 1,000 to dialyze the product for two weeks; use the rotary evaporator again to concentrate the product at 80°C , Then freeze-drying (-45℃, 48h) to obtain brown powder as nitrogen-doped carbon quantum dots; the obtained nitrogen-doped carbon quantum dots and titanium dioxide are mixed in a mass ratio of 5:95, and then placed in an oven at 80℃ Aging. Subsequently, the material is dried and put into a 5% methanol solution to catalyze hydrogen production under sunlight.

Embodiment 3

[0041] At room temperature, put 5g of glucose and 80ml of acetonitrile into the inner tank of a polytetrafluoroethylene hydrothermal kettle for a hydrothermal reaction (reaction condition is 200°C, 14h); after the reaction kettle is cooled to room temperature, the product is suction filtered, and the filtrate is collected. Wash the filtrate repeatedly with dichloromethane; use a rotary evaporator to evaporate the filtrate at 60°C, and after concentration, use a dialysis bag with a cutoff molecular weight of 300 to dialyze for two weeks; use the rotary evaporator again to concentrate the product at 60°C , Then freeze-drying (-45℃, 48h) to obtain brown powder as nitrogen-doped carbon quantum dots; the obtained nitrogen-doped carbon quantum dots and titanium dioxide are mixed in a mass ratio of 10:90, and then placed in an oven at 80℃ Aging. Subsequently, the material is dried and put into a 5% methanol solution to catalyze hydrogen production under sunlight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com