Engine tail gas cleanup device

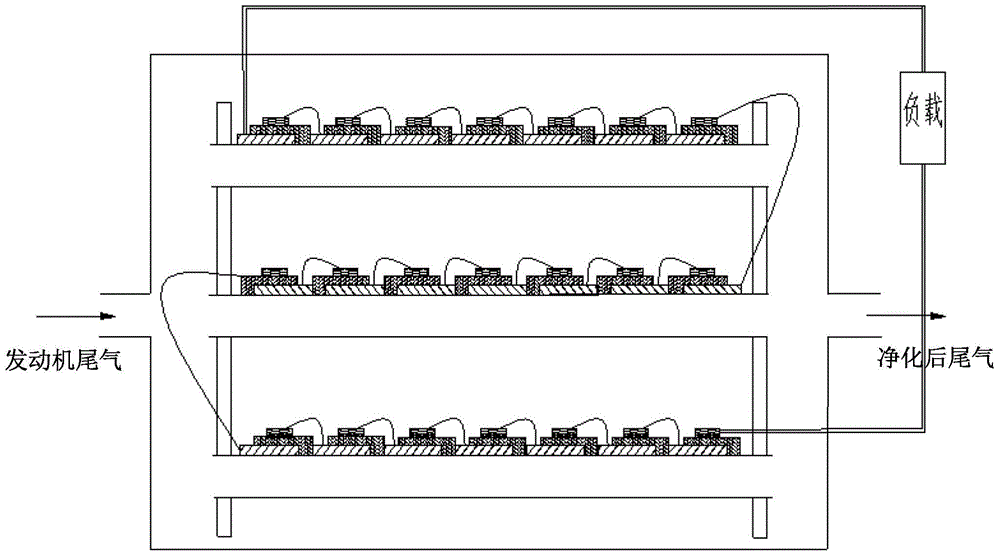

A technology for exhaust gas purification devices and engines, which is applied to exhaust devices, engine components, machines/engines, etc., can solve the problems of easy volatilization of materials, slow start-up, and difficult preparation, and achieve the requirements of reducing materials and manufacturing processes, reducing Costs and Procedures, Effects of Improving Catalytic Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

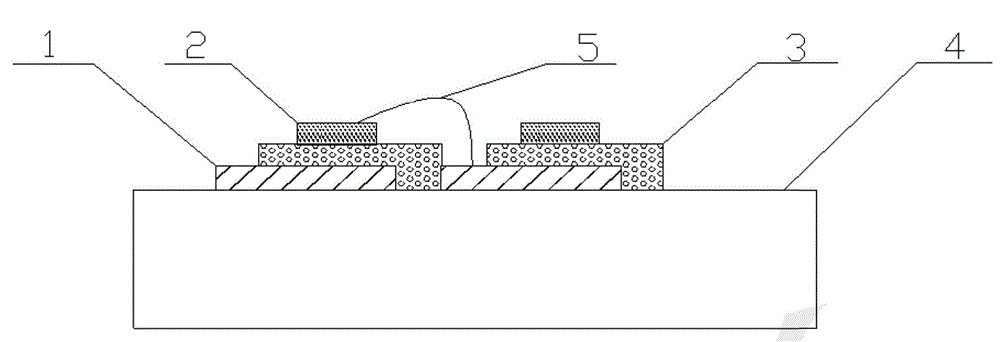

[0039] Correspondingly, a method for preparing a single solid oxide fuel cell with a support, the steps are:

[0040]1) According to the chemical composition of the perovskite-type catalyst, take the nitrate of the corresponding metal ion, make it into a gel, dry it, and grind it to obtain the catalyst powder;

[0041] 2) Mix the catalyst powder, PSZ powder, and organic solvent prepared in the previous step to make a spinning solution, and obtain a hollow fiber green body through a spinning machine, cut into sections, and then calcined to make a porous hollow fiber support;

[0042] 3) Dissolving the cermet powder in an organic solvent, coating it on the support, and calcining it to obtain the anode layer;

[0043] 4) The electrolyte material is dissolved in an organic solvent, coated on one end of the surface of the anode layer, and one end is set aside, and calcined to obtain the electrolyte layer; the electrolyte material is ZrO 2 Base electrolyte material, CeO 2 Base ele...

Embodiment 1

[0053] In this embodiment, the battery anode material is Ni-YSZ powder, and the battery cathode material uses perovskite catalyst powder La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ , with La (NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 , Co(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O is prepared by the sol-gel method. Specifically, weigh the nitrate with a molar ratio of lanthanum, strontium, cobalt, and iron of 3:2:1:4, dissolve it in deionized water, and stir it in a constant temperature water bath at 80°C to form a nitrate solution. , adding citric acid monohydrate with a molar ratio of 2:1 to the metal ion, and then adding polyethylene glycol with a molar ratio of 6:1 to the metal ion to the solution, stirring in a constant temperature water bath at 80°C for 2 hours to form a metal ion chelating solution, Then put the chelating solution into a constant temperature drying oven at 200°C for high temperature drying for 12 hours to form a gel. Then the gel was put into a muffle furnace, ca...

Embodiment 2

[0058] The difference between this embodiment and the first embodiment is that the cathode powder La in the first embodiment 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ Change to La 0.6 Sr 0.4 co 0.2 Fe 0.4 Cu 0.4 o 3-δ , other conditions are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com