High purity alumina powder preparing device and method

A technology of high-purity alumina and powder, applied in the direction of anodic oxidation, etc., can solve the problems of short process flow, large consumption of production investment funds, complicated process, etc., and achieve the effects of reducing mutual wrapping, complete hydrolysis reaction, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

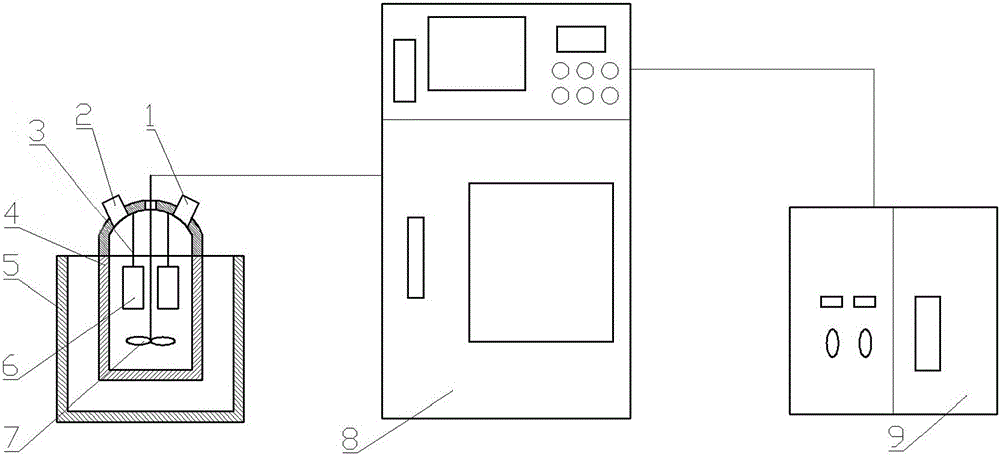

[0028] A device for preparing high -pure aluminum oxide powder, see figure 1 , Including reactors, mixers, aluminum plates, water -cooled sleeves, and micro -arc oxidation power supply, the mixer is set inside the reactor, and the water -cold sleeve (FRP) is set outside the reactor.The negative connection of the inner orchid (316L stainless steel) and the micro -arc oxidation power supply, the aluminum plate (1000 grams, 99.99%of the purity) is suspended inside the reactor through the aluminum line (purity ≥99.95%), and the positive electrode of the micro -arc oxidation power supplyconnect.The top of the reaction kettle is provided with an observation port and exhaust port, which is also connected to the regulator.

[0029] The preparation steps are as follows:

[0030] (1) Add high pure water with a resistance of 10mΩ to 2 / 3 of the volume of the resistance in the reaction kettle, and completely immerse in aluminum plates;

[0031] (2) Start the micro -arc oxidation power supply, ...

Embodiment 2

[0034] A device for preparing high -pure aluminum oxide powder is the same as Example 1.

[0035] The preparation steps are as follows:

[0036] (1) Add high pure water with a resistance of 10mΩ to 2 / 3 of the volume of the resistance in the reaction kettle, and completely immerse in aluminum plates;

[0037] (2) Start the micro -arc oxidation power supply, gradually increase the power supply voltage to 400V, the frequency is 1500Hz, and start the mixer to control the mixing rate of 200 rpm.℃, the response time is 60 minutes, 754 grams of remaining metal aluminum slices;

[0038](3) Disgle the power supply (the aluminum plate will continue to react for a period of time). After the temperature in the reaction kettle cools to the room temperature and stops the reaction, the generated aluminum hydroxide gel is filtered and dried.Burning at 1200 ° C for 1 hour, 615 grams of aluminum oxide powder was obtained, with an output rate of 98.9%and a purity of 99.995%.

Embodiment 3

[0040] A device for preparing high -pure aluminum oxide powder is the same as Example 1.

[0041] The preparation steps are as follows:

[0042] (1) Add high pure water with a resistance of 18MΩ to 2 / 3 of the volume of the resistance in the reaction kettle, and completely immerse in aluminum plates;

[0043] (2) Start the micro -arc oxidation power supply, gradually increase the power supply voltage to 475V, the frequency is 1200Hz, and start the mixer to control the mixing rate of 100 rpm.℃, the response time is 30 minutes, 671 grams of the remaining metal aluminum tablets;

[0044] (3) Disgle the power supply (the aluminum plate will continue to react for a period of time). After the temperature in the reaction kettle is cooled to the room temperature and stops the reaction, the generated aluminum hydroxide gel is filtered and dried.Burning for 1 hour at 1200 ° C, 449 grams of aluminum oxide powder was obtained, with an output rate of 96.6%and a purity of 99.999%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com