Stain resistant environment-friendly color-coated sheet

An anti-staining and color-coated board technology, applied in the field of materials, can solve the problems of reducing the weather resistance and stain resistance of polyvinylidene fluoride, affecting the anti-corrosion period, and the effect is not significant, so as to ensure the anti-staining and anti-staining properties. Weather resistance, excellent performance, and the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

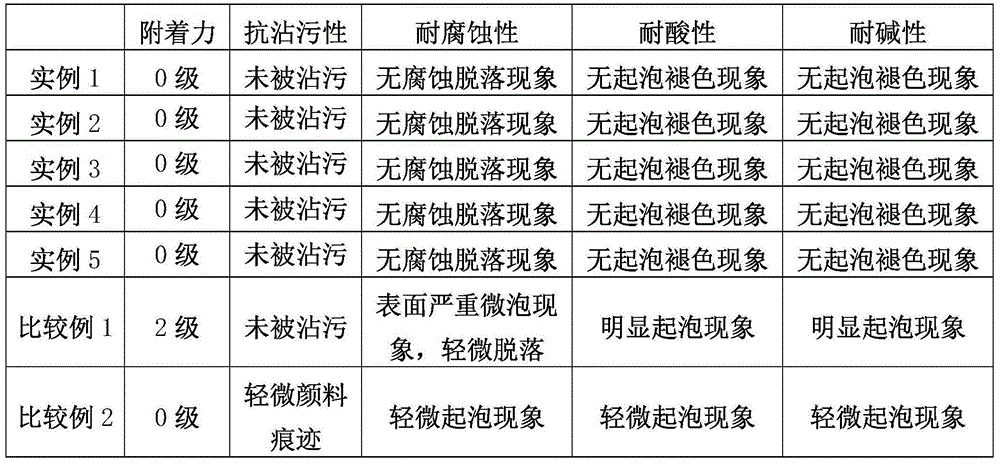

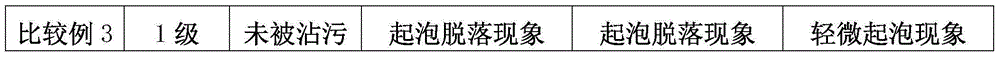

Examples

example 1

[0027] A color-coated board with high stain resistance and high weather resistance and environmental protection, which includes: a substrate, the upper surface of the substrate is sequentially provided with a first chemical passivation layer, a low-fluorine undercoat, and a high-fluorine topcoat. The lower surface of the substrate is sequentially provided with a second chemical passivation layer and a back coating layer from top to bottom;

[0028] Wherein, the substrate is a galvanized steel sheet, and the galvanized layer of the steel sheet also includes 2wt% aluminum;

[0029] The high fluorine top coat includes 3wt% 1,4-butanediol, 1wt% silicon dioxide, 1wt% aluminum oxide, and 95wt% polyvinylidene fluoride, wherein the high fluorine top coat The thickness is 20μm;

[0030] The low-fluorine primer layer includes 15wt% 4-hydroxybutyl vinyl ether, 10% polyvinyl alcohol, and 75wt% polyvinylidene fluoride, wherein the low-fluorine primer layer has a thickness of 10 μm;

[00...

example 2

[0034] A color-coated board with high stain resistance and high weather resistance and environmental protection, which includes: a substrate, the upper surface of the substrate is sequentially provided with a first chemical passivation layer, a low-fluorine undercoat, and a high-fluorine topcoat. The lower surface of the substrate is sequentially provided with a second chemical passivation layer and a back coating layer from top to bottom;

[0035] Wherein, the substrate is a galvanized steel sheet, and the galvanized layer of the steel sheet also includes 5wt% aluminum;

[0036] The high fluorine top coat includes 5wt% 1,4-butanediol, 2wt% silicon dioxide, 3wt% aluminum oxide, and 90wt% polyvinylidene fluoride, wherein the high fluorine top coat The thickness is 25 μm;

[0037] The low-fluorine primer layer includes 25wt% 4-hydroxybutyl vinyl ether, 20% polyvinyl alcohol, and 55wt% polyvinylidene fluoride, wherein the low-fluorine primer layer has a thickness of 15 μm;

[0...

example 3

[0041] A color-coated board with high stain resistance and high weather resistance and environmental protection, which includes: a substrate, the upper surface of the substrate is sequentially provided with a first chemical passivation layer, a low-fluorine undercoat, and a high-fluorine topcoat. The lower surface of the substrate is sequentially provided with a second chemical passivation layer and a back coating layer from top to bottom;

[0042] Wherein, the substrate is a galvanized steel sheet, and the galvanized layer of the steel sheet also includes 3wt% aluminum;

[0043] The high fluorine top coat includes 4wt% 1,4-butanediol, 2wt% silicon dioxide, 2wt% aluminum oxide, and 92wt% polyvinylidene fluoride, wherein the high fluorine top coat The thickness is 22μm;

[0044] The low-fluorine primer layer includes 20 wt% 4-hydroxybutyl vinyl ether, 15% polyvinyl alcohol, and 65 wt% polyvinylidene fluoride, wherein the low-fluorine primer layer has a thickness of 12 μm;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com