Abamectin microcapsule powder prepared from lignin-based wall material and method for preparing abamectin microcapsule powder by use of lignin-based wall material

A technology of abamectin and microcapsule powder, which is applied in the field of abamectin microcapsule powder, can solve the problems of low-efficiency embedding methods, no innovation, and low loading rate of the original drug, so as to prevent ultraviolet light solution, easy to control, and solve the effect of not being resistant to sunlight photolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Dissolve 100g of sodium lignosulfonate in 400g of water, adjust the pH to 12, activate in a water bath at 50°C for 0.5h, add 50g of diethylenetriamine, slowly add 50g of formaldehyde dropwise, complete the dropwise addition within 0.5h, and raise the temperature to 70°C °C, the reaction was continued for 4 h to obtain a sodium amino lignosulfonate solution. The obtained sodium amino lignosulfonate solution is extracted with ethanol, and the residual solid after extraction is washed with petroleum ether and then freeze-dried to obtain purified powdery sodium amino lignosulfonate.

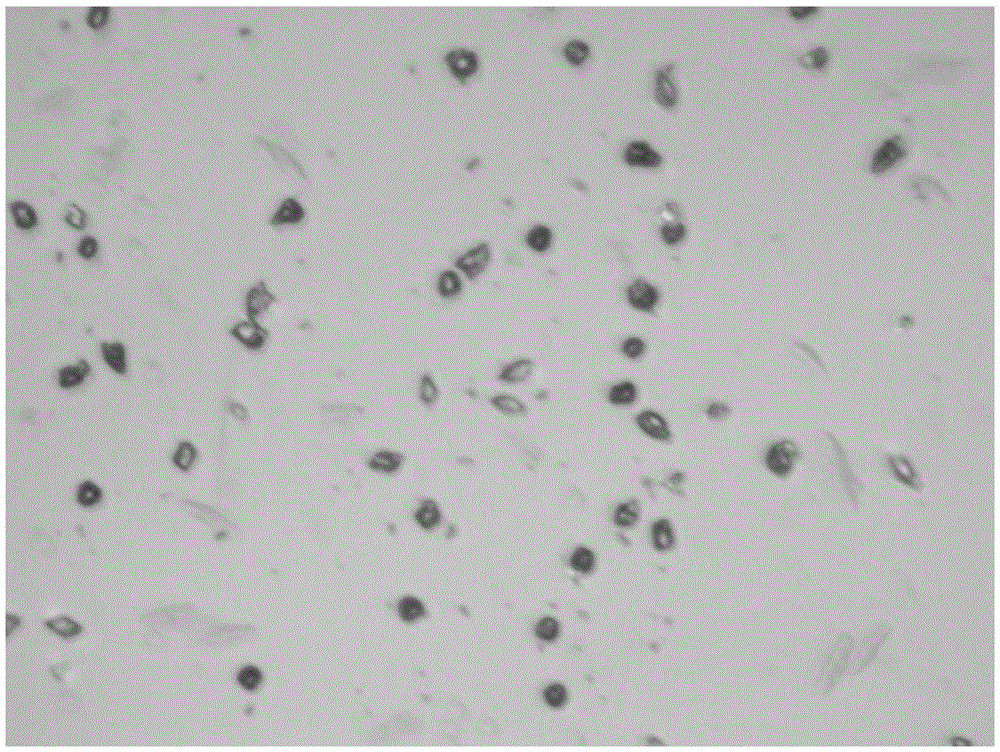

[0045] Dissolve 100g of purified amino lignosulfonate sodium wall material, 8g of sodium lauryl sulfate and 5g of polyethylene glycol 1000 in 200g of water to prepare an aqueous solution to obtain the aqueous phase; dissolve 100g of abamectin in 500g of dichloromethane to obtain the organic phase. Add the organic phase to the water phase evenly within 30 minutes at 1000rpm, and then shear for...

Embodiment 2

[0047] Dissolve 100g of sodium lignosulfonate in 150g of water, adjust the pH to 10, activate in a water bath at 60°C for 1.0h, add 20g of triethylamine, slowly add 20g of acetaldehyde dropwise, complete the dropwise addition within 1h, and raise the temperature to 80°C , Continue to react for 2h to obtain sodium amino lignosulfonate solution. The obtained sodium amino lignosulfonate solution is extracted with ethanol, and the residual solid after extraction is washed with petroleum ether and then freeze-dried to obtain purified powdery sodium amino lignosulfonate.

[0048] 100g of purified amino lignosulfonate wall material and 5g of Tween-80 were dissolved in 350g of water to prepare an aqueous solution to obtain an aqueous phase; 20g of abamectin was dissolved in 200g of dimethyl sulfoxide to obtain an organic phase . Add the organic phase to the water phase evenly within 30 minutes at 800rpm, and then shear for 10 minutes; then adjust the pH of the dispersion to 6.5 with ...

Embodiment 3

[0050] Dissolve 100g of sodium lignosulfonate in 200g of water, adjust the pH to 11, activate in a 70°C water bath for 1.0h, add 200g of diethylamine, slowly add 200g of propionaldehyde dropwise, complete the dropwise addition within 1h, and raise the temperature to 90°C , Continue to react for 3h to obtain sodium amino lignosulfonate solution. The obtained sodium amino lignosulfonate solution is extracted with ethanol, and the residual solid after extraction is washed with petroleum ether and then freeze-dried to obtain purified powdery sodium amino lignosulfonate.

[0051] 100g of purified amino lignosulfonate wall material and 12g of sodium dodecylbenzenesulfonate are dissolved in 400g of water to prepare an aqueous solution to obtain an aqueous phase; 80g of abamectin are dissolved in 100g of pyrrolidone and 200g of ethanol mixed solvent , an organic phase was obtained. Add the organic phase to the water phase evenly within 30 minutes at 1000rpm, and then shear for 20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com