Cu2+-EDTA-Fe3O4 magnetic grain, preparation method and application

A technology of -edta-fe3o4 and edta-fe3o4, applied in the field of superparamagnetic functional materials, can solve the problem that chromatography is not suitable for direct processing of biological samples, and achieve the effects of excellent specificity, uniform particle size distribution, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

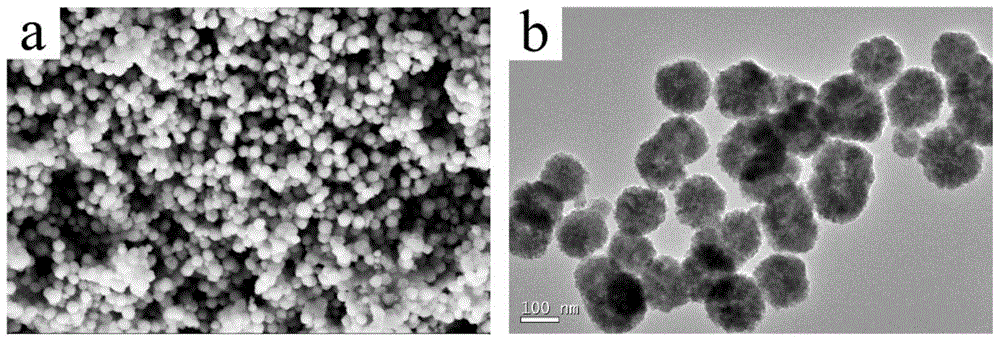

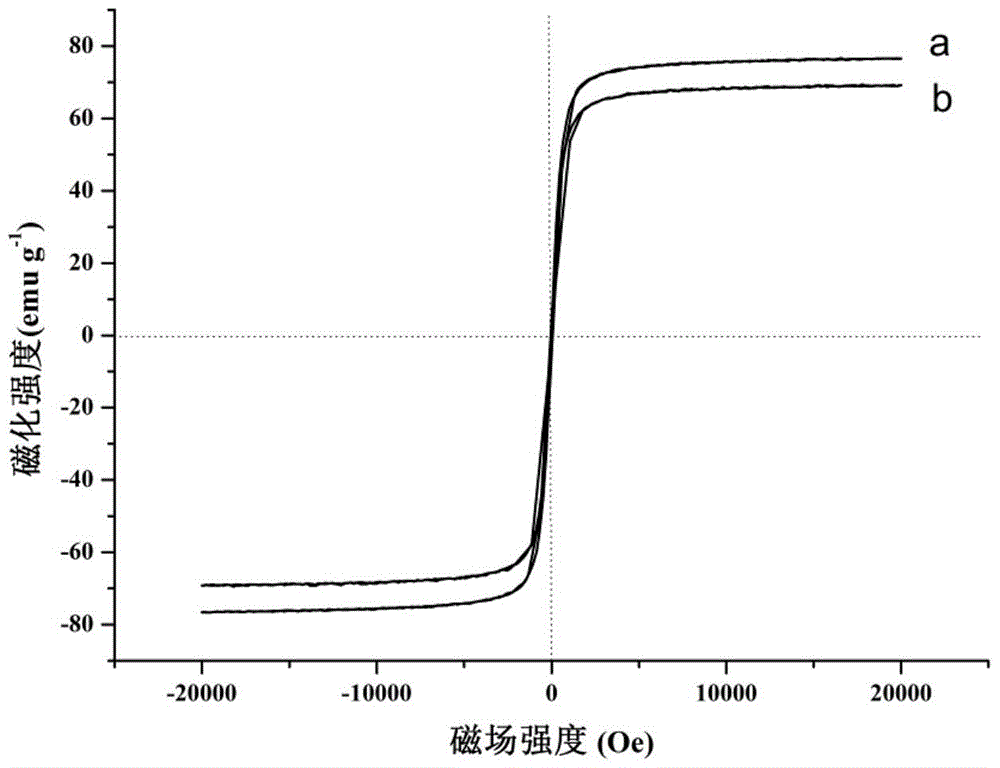

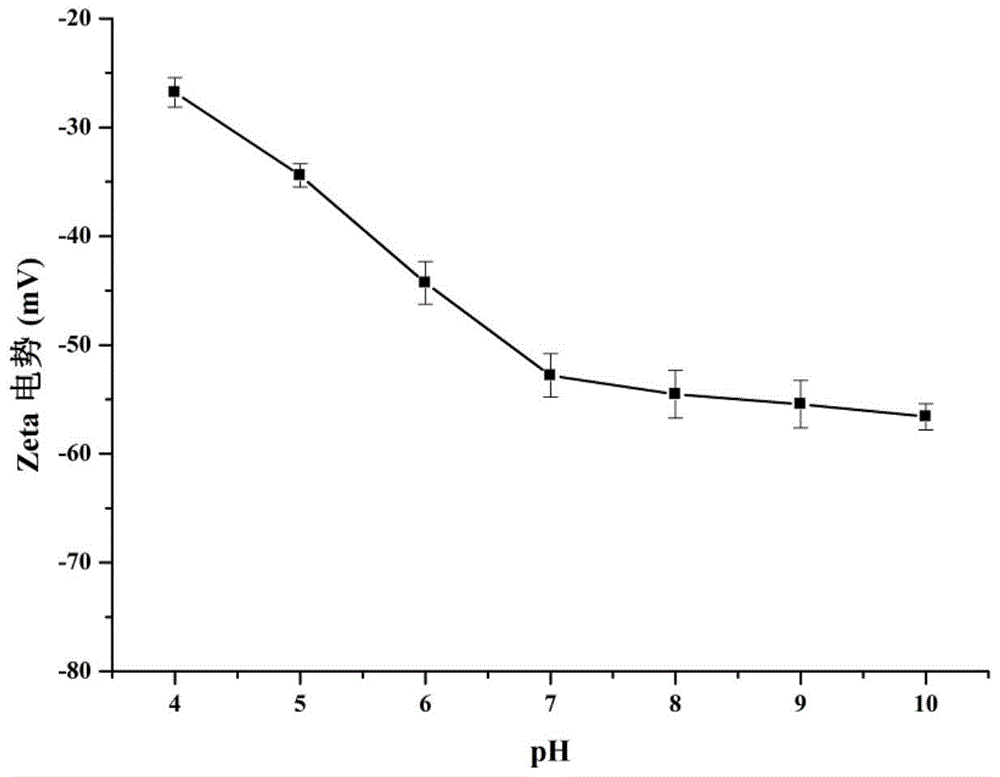

[0038] Example 1: Cu 2+ -EDTA-Fe 3 o 4 Preparation of magnetic particles

[0039] (1) Preparation of EDTA-Fe by hydrothermal method 3 o 4 Magnetic particles, accurately weigh 0.5g FeCl 3 ·6H 2 O (1.85mmol), add 15mL ethylene glycol and 15mL diethylene glycol to assist in ultrasonic dissolution, then add 1.8g urea (30mmol) and 0.35g disodium edetate (1.04mmol) while stirring, and stir at 70°C for 30min A uniform solution was formed, and the solution was poured into a 50 mL Teflon autoclave, placed in an oven, and then heated to 200°C for 10 hours of reaction. After the reaction, cool to room temperature, separate the product under an external magnetic field and wash thoroughly with ethanol and deionized water for 3 times, and finally dry to obtain the product EDTA-Fe 3 o 4 magnetic particles.

[0040] (2) EDTA-Fe 3 o 4 The magnetic particles were added to 0.2mmol / L copper sulfate solution, ultrasonicated for 5min at room temperature, the product was separated under a...

Embodiment 2

[0044] Example 2: Cu 2+ -EDTA-Fe 3 o 4 Preparation of magnetic particles

[0045] (1) Preparation of EDTA-Fe by hydrothermal method 3 o 4 Magnetic particles, accurately weigh 0.39gFeCl 3 ·6H 2 O (1.44mmol), add 13.4mL ethylene glycol and 16.6mL diethylene glycol to assist in ultrasonic dissolution, then add 1.44g urea (24mmol) and 0.28g disodium edetate (0.83mmol) while stirring, at 50°C Stir for 30 minutes to form a homogeneous solution, pour the solution into a 50 mL Teflon autoclave, put it in an oven, then raise the temperature to 190°C, and react for 12 hours. After the reaction, cool to room temperature, separate the product under an external magnetic field and wash thoroughly with ethanol and deionized water for 3 times, and finally dry to obtain the product EDTA-Fe 3 o 4 magnetic particles.

[0046] (2) EDTA-Fe 3 o 4 Add the magnetic particles into 0.1mmol / L copper chloride solution, ultrasonicate for 3min at room temperature, separate the product under an e...

Embodiment 3

[0047] Example 3: Cu 2+ -EDTA-Fe 3 o 4 Preparation of magnetic particles

[0048] (1) Preparation of EDTA-Fe by hydrothermal method 3 o 4 Magnetic particles, accurately weigh 0.61gFeCl 3 ·6H 2 O (2.26mmol), add 16.4mL of ethylene glycol and 13.6mL of diethylene glycol to assist in ultrasonic dissolution, then add 2.16g of urea (36mmol) and 0.42g of disodium edetate (1.24mmol) while stirring, at 60°C Stir for 30 minutes to form a homogeneous solution, pour the solution into a 50 mL Teflon autoclave, put it in an oven, then raise the temperature to 210° C., and react for 8 hours. After the reaction, cool to room temperature, separate the product under an external magnetic field and wash thoroughly with ethanol and deionized water for 3 times, and finally dry to obtain the product EDTA-Fe 3 o 4 magnetic particles.

[0049] (2) EDTA-Fe 3 o 4 Add the magnetic particles into 0.3mmol / L copper nitrate solution, ultrasonicate for 10min at room temperature, separate the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com