Method for improving electrochemical properties of lithium iron phosphate with copper/graphene

A lithium iron phosphate battery, lithium iron phosphate technology, applied in electrochemical generators, circuits, electrical components, etc., can solve the problems of difficult control of the operation process, complicated steps, long time, etc., to improve the rate discharge performance and cycle stability. performance, simplicity of operation and process, high degree of binding and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment comprises the following steps: preparing 200mL of a mixed aqueous solution containing 0.01g of graphene oxide and 0.08g of copper sulfate; adding 2g of commercial carbon-coated lithium iron phosphate powder to the above mixed solution, and stirring at a speed of 180 rpm Stir for 2 minutes; wash the lithium iron phosphate powder after the above reaction with water, filter it with suction, and vacuum-dry it in a vacuum drying oven at -0.08MPa.

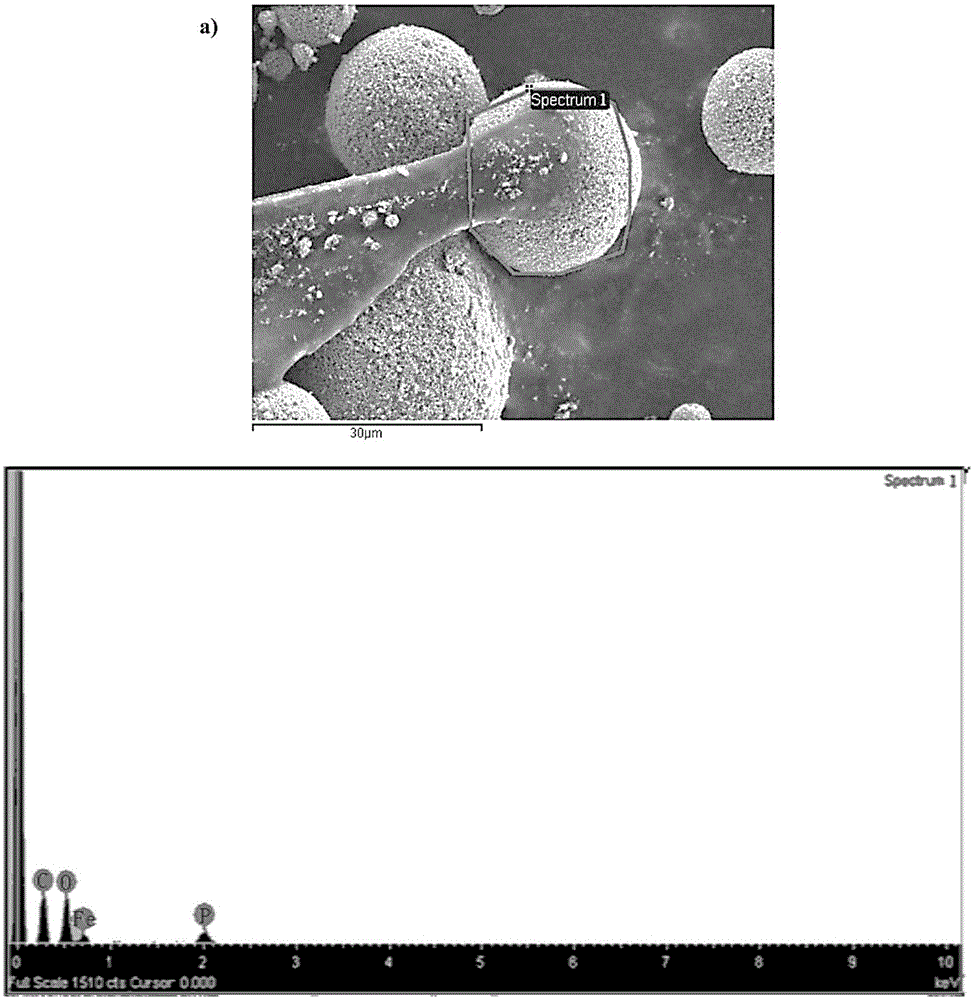

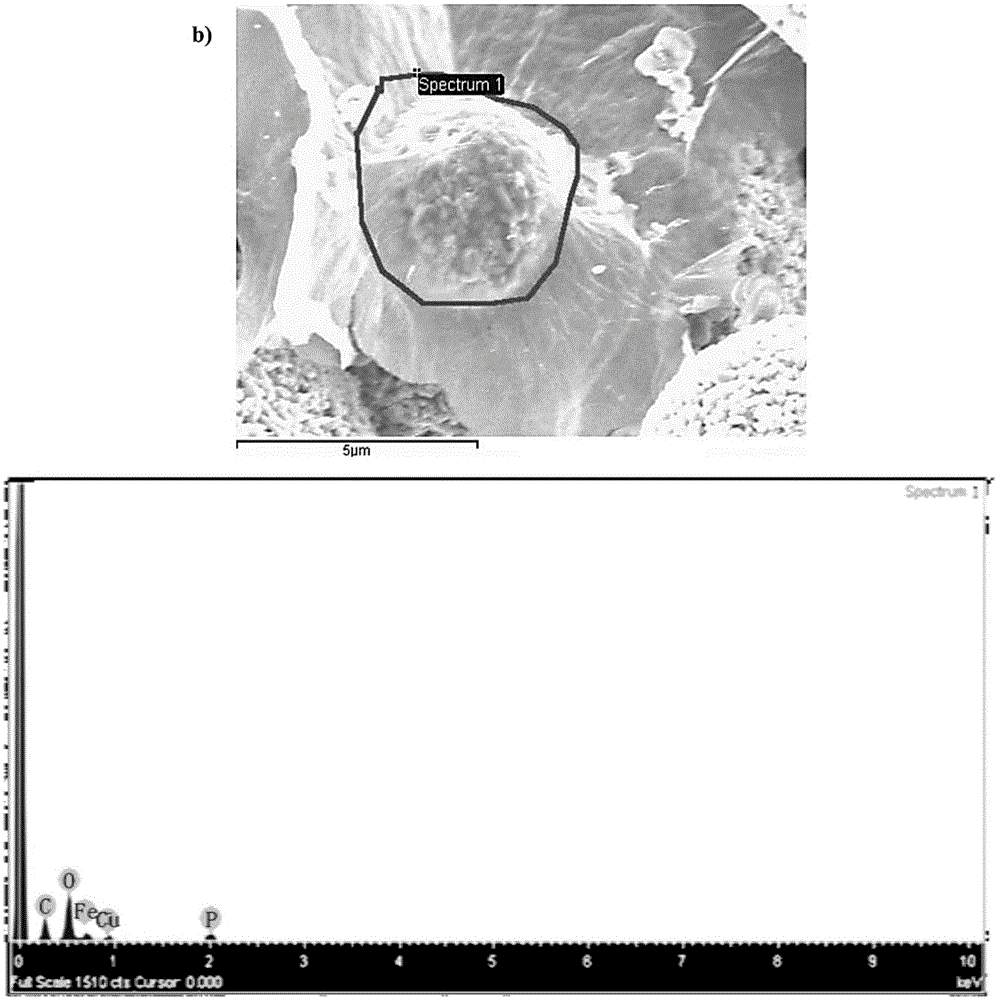

[0032] Such as figure 1 As shown, compared with the untreated lithium iron phosphate powder (a), the copper / graphene composite surface-treated lithium iron phosphate powder (b) has an obvious graphene layer on the surface, and the existence of copper element is detected by electron spectroscopy. That is, (b) has the dual morphology characteristics of chemically reduced graphene and copper.

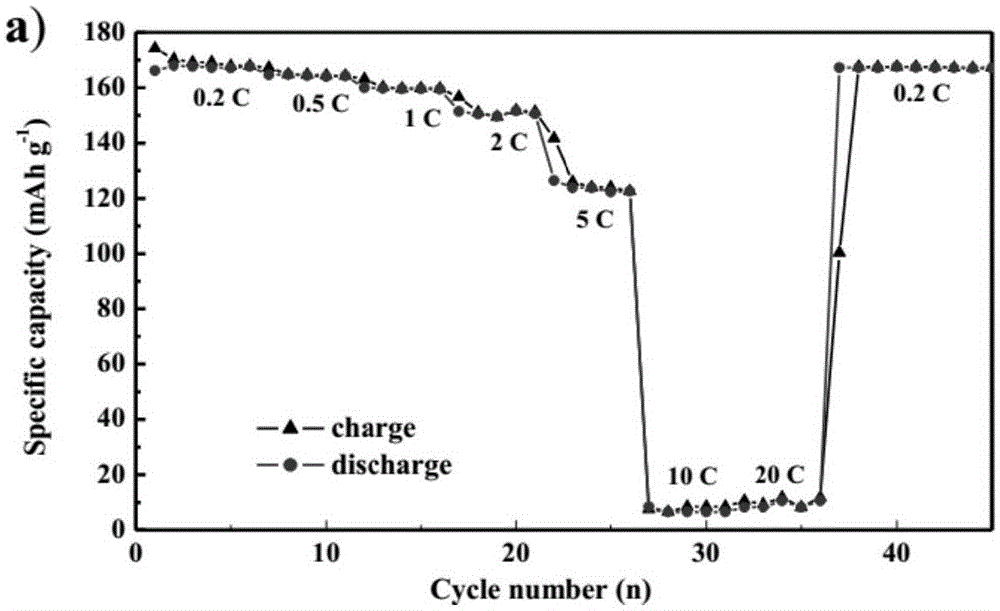

[0033] Such as figure 2 with image 3 As shown, using N-methylpyrrolidone (NMP) as solvent, according to the mass ...

Embodiment 2

[0036] The present embodiment comprises the following steps: preparing 150mL of a mixed aqueous solution containing 0.2g of graphene oxide and 0.02g of copper chloride; adding 10g of commercial carbon-coated lithium iron phosphate powder to the above mixed solution, and stirring at a speed of 120 rpm Stir for 40 minutes; wash the lithium iron phosphate powder after the above reaction with water, filter it with suction, and vacuum-dry it in a vacuum drying oven at -0.08MPa.

[0037] The charge and discharge performance test was carried out on the lithium iron phosphate samples before and after treatment. The results of charge-discharge cycle test show that the specific capacity at 0.2C and 20C is about 147 and 75mAh / g, respectively.

Embodiment 3

[0039] The present embodiment comprises the following steps: preparing 100mL of a mixed aqueous solution containing 0.003g of graphene oxide and 0.04g of copper nitrate; adding 1g of commercial carbon-coated lithium iron phosphate powder to the above mixed solution, stirring at a stirring speed of 300 rpm 10min; the lithium iron phosphate powder after the above reaction was washed with water, filtered with suction, and placed in a -0.08MPa vacuum drying oven for vacuum drying.

[0040] The charge and discharge performance test was carried out on the lithium iron phosphate samples before and after treatment. The test results of charge-discharge cycles show that the specific capacities at 0.2C and 20C are about 155 and 69mAh / g, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com