Building and application of engineered strains capable of producing xylitol and ethanol at high temperature simultaneously with high yield

A technology of xylitol and xylose, applied in the biological field, can solve problems such as low efficiency, difficulty in removing the inhibitory effect of glucose, and insufficient efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

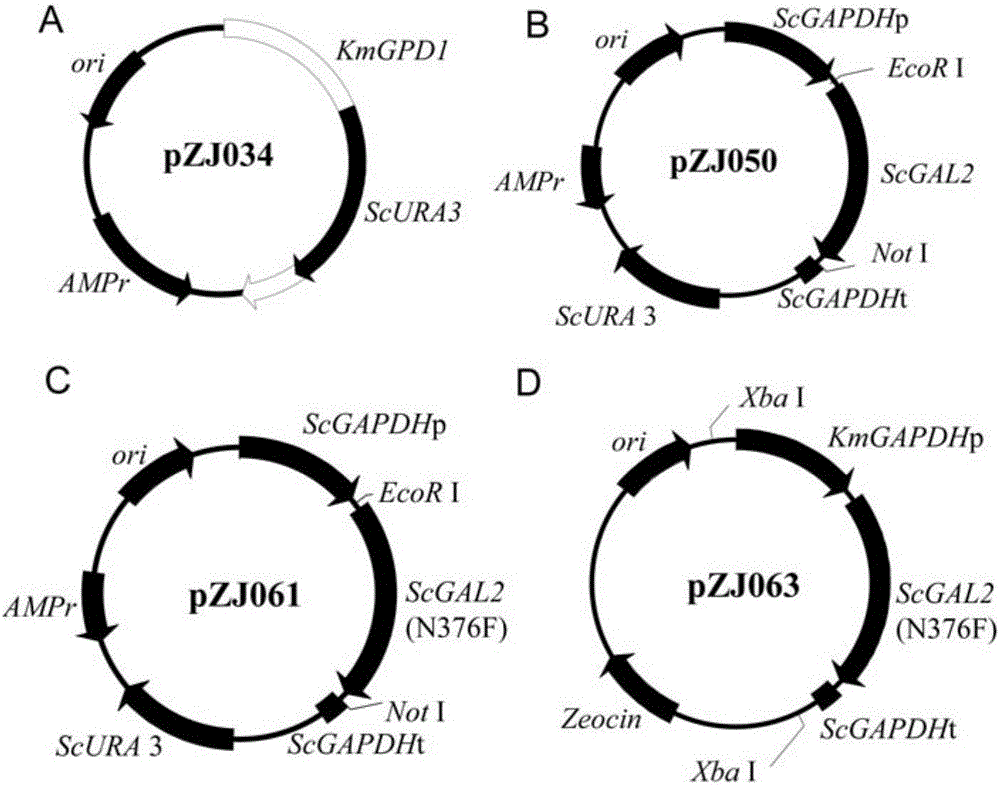

Method used

Image

Examples

Embodiment 1

[0042] The preparation of embodiment 1 bacterial strain:

[0043] 1. The specific operation steps for extracting the yeast genome are as follows:

[0044] ①. Kluyveromyces marxii NBRC177 strain was streaked on a YPD plate, a single clone was picked, inserted into 5ml liquid YPD, cultured at 37°C, 250rpm for 24h.

[0045] ②. Collect the bacteria by centrifugation at 12000rpm at room temperature for 5sec, and discard the supernatant.

[0046] ③. Resuspend the bacteria in 500μl distilled water, centrifuge at 12000rpm for 5sec to collect the bacteria, and discard the supernatant.

[0047] ④. Take 200μl laboratory self-made 1xbreaking buffer (TritonX-100 (2% (w / v)), SDS (1% (w / v)), NaCl (100mM), Tris-Cl (10mM, pH8.0 ), EDTA (1mM)) to resuspend the bacteria, and transfer the bacteria solution into an EP tube containing 0.3g glass beads (425-600um, sigma, USA).

[0048] ⑤. After adding 200 μl of phenol-chloroform solution, shake at high speed for 3 minutes, and then add 200 μl o...

Embodiment 2

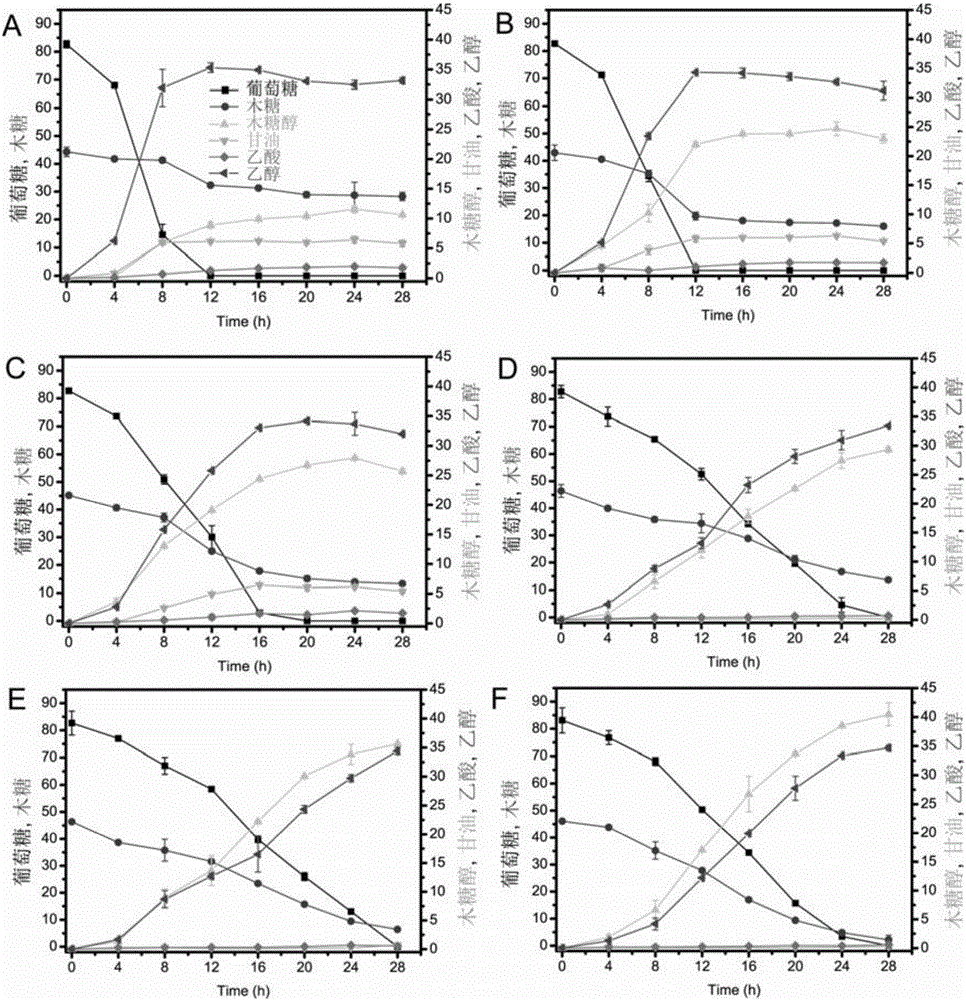

[0189] Fermentation situation of various process bacterial strains constructed in embodiment 2

[0190] Comparison of fermentation results of various process strains constructed

[0191] This example is used to compare the effects of co-fermentation of xylose and glucose to produce xylitol and ethanol by various process strains constructed. The results showed that the co-fermentation ability of the strain constructed by overexpressing the ScGAL2-N376F gene was gradually improved, and the final strain could convert almost all xylose into xylitol and all glucose into ethanol. In addition, knockdown of KmGPD1 almost completely disappeared the by-product glycerol.

[0192] 1. Recover strains on YPD medium plates. Control strain: YZJ015. Experimental strains: YZJ103, YZJ109, YZJ115, YZJ118, YZJ119. Cultured at 37°C for 1 day.

[0193] 2. Pick out single clones respectively, and connect them to 5ml liquid YPD medium. 37°C, 250rpm, overnight.

[0194] 3. Prepare 18 bottles of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com