Silicon dioxide-coated fluorinated lithium cobalt phosphate and preparation method thereof

A technology of fluorinated cobalt lithium phosphate and silicon dioxide, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as poor cycle performance, achieve improved electrochemical performance, good reaction reversibility and structural stability, excellent The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

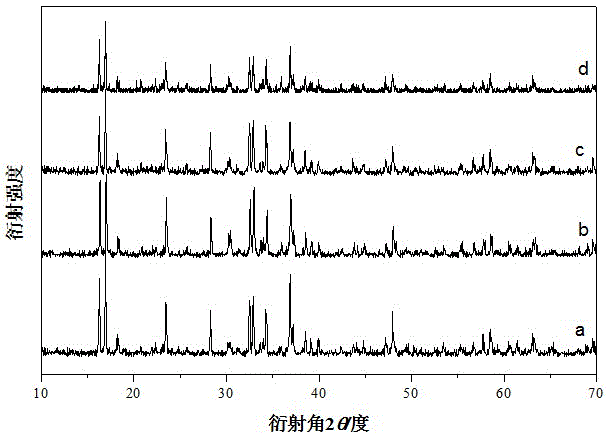

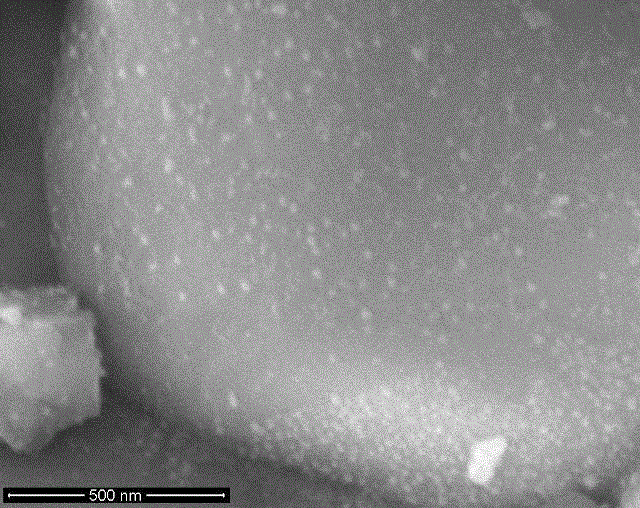

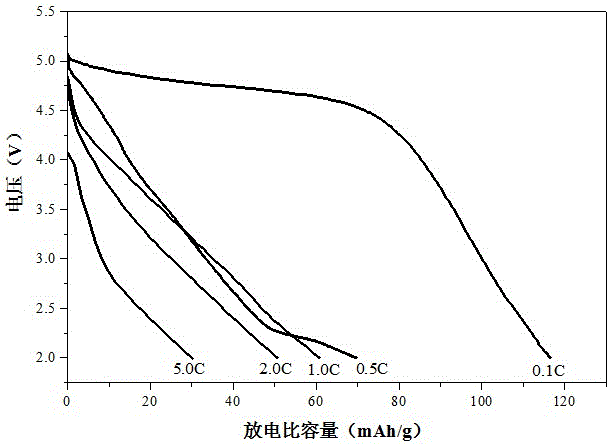

[0023] Add 0.02mol lithium fluoride, 0.02mol cobalt acetate, 0.02mol phosphoric acid, and 0.02mol lithium hydroxide into 35ml deionized water respectively, stir for 2h to make it evenly mixed, then transfer the mixed solution to the reaction kettle, and water at 210℃ Heat for 10h, then cool the reaction kettle to room temperature naturally, take out the product and dry it at 80℃ overnight, take out the tablet, and finally calcinate in a tube furnace at 350℃ for 6h and then 650℃ for 6h to obtain the product Li 2 CoPO 4 F. Then, weigh a certain amount of silica dispersion into a 50ml dry beaker, add 20ml of deionized water, magnetically stir until the mixture is uniform, and then add a certain amount of Li prepared by the above method 2 CoPO 4 F, continue to stir, then vacuum dry at 90°C overnight, take it out, and grind thoroughly in a quartz mortar to obtain silica-coated Li 2 CoPO 4 F material. For the X-ray powder diffraction pattern of the sample, see figure 1 , It shows tha...

Embodiment 2

[0025] Add 0.02mol of ammonium fluoride, 0.02mol of cobalt oxalate, 0.02mol of ammonium dihydrogen phosphate, and 0.02mol of lithium carbonate to 30ml of deionized water, stir for 2h to make them evenly mixed, and then transfer the mixed solution to the reaction kettle. Hydrothermally heated at ℃ for 14h, then the reaction kettle was naturally cooled to room temperature, the product was taken out and dried overnight at 80℃, taken out for grinding, tableting, and finally calcined at 300℃ for 6h in a tube furnace under a hydrogen / argon mixed gas atmosphere, and then Calcined at 640℃ for 6h to obtain the product Li 2 CoPO 4 F. Then, weigh a certain amount of silica particles into a 50ml dry beaker, add 20ml of hydrofluoric acid, manually stir and mix evenly, and then add a certain amount of Li prepared by the above method 2 CoPO 4 F, continue to stir, then dry at 90°C in a blast drying box, take it out, and grind it fully in an agate mortar to obtain silica-coated Li 2 CoPO 4 F mat...

Embodiment 3

[0027] 0.02mol lithium hydroxide, 0.02mol cobalt tetroxide, 0.02mol ammonium hydrogen phosphate were mixed and ball milled for 3h, and then calcined at 400℃ and 800℃ for 10h respectively to obtain LiCoPO 4 . Will get LiCoPO 4 Then mixed with LiF and ball milled and calcined at 700℃ for 1.5h under argon atmosphere to obtain the product Li 2 CoPO 4 F. Then, weigh a certain amount of silica powder and place it in a 100ml beaker, add 30ml of ethanol, mechanically stir and mix evenly, and then add a certain amount of Li prepared by the above method 2 CoPO 4 F, continue to stir, dry in a vacuum drying oven at 60°C, take it out, and grind it in an alumina mortar to obtain silica-coated Li 2 CoPO 4 F material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com