Nano-composite material for catalytically decomposing formaldehyde at normal temperature and method for preparing nano-composite material

A nanocomposite material that catalyzes formaldehyde, applied in the field of air purification application materials, can solve problems such as difficult to use, small specific surface area, and limited catalytic activity of materials, and achieve the effect of huge specific surface area, high activity, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

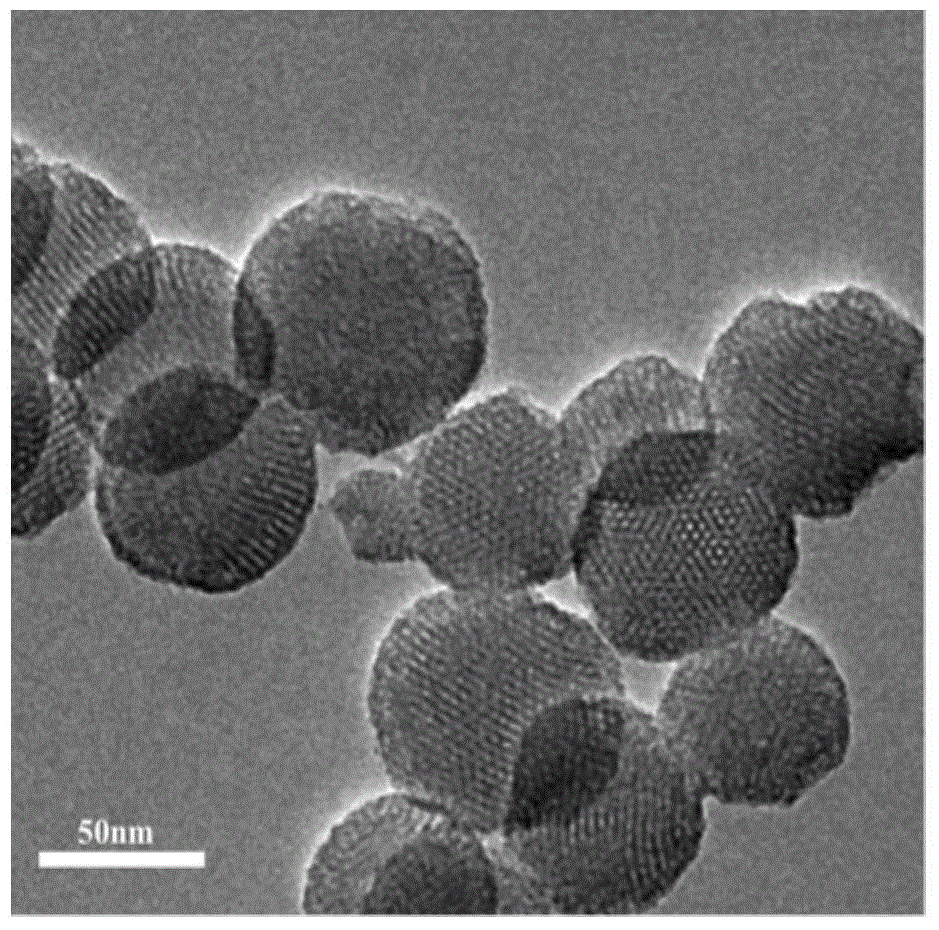

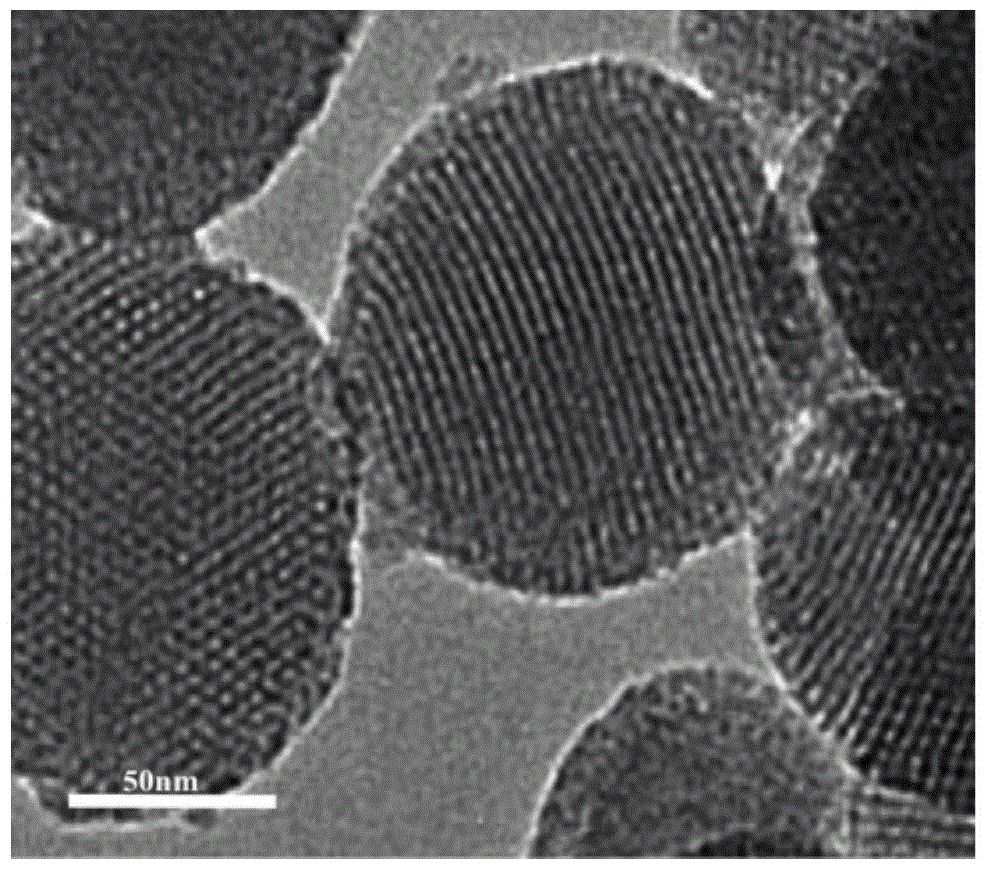

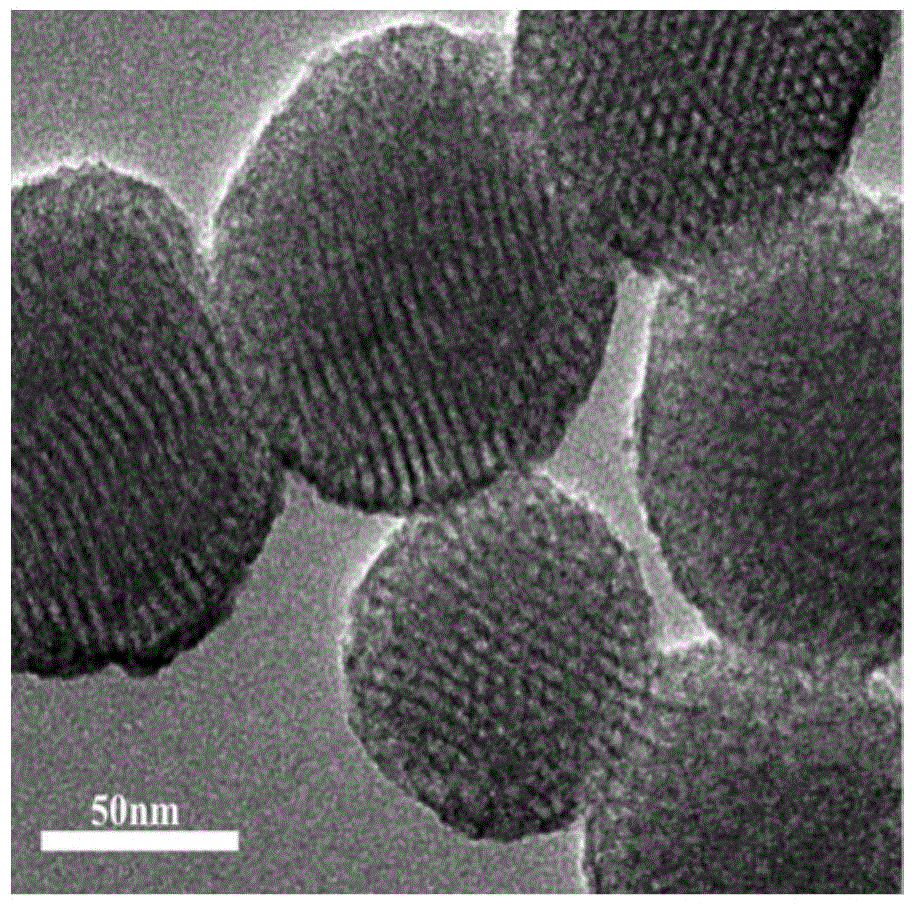

Image

Examples

Embodiment 1

[0040] Dissolve 14.71g of manganese sulfate monohydrate, 2.50g of copper sulfate pentahydrate and 1.33g of cerium nitrate hexahydrate in 200mL of pure water, and fully stir to form a clear mixed salt solution; Alkyl trimethyl ammonium bromide was mixed and dissolved in 1000 mL of pure water to obtain a silicon source solution, and 14 mL of 1mol / L sodium hydroxide was added to adjust the pH of the solution to 9.0, and heated to 30 ° C; quickly add the above-mentioned silicon source solution to the above-mentioned silicon source solution. Mix the salt solution and stir vigorously; after the reaction for 2 hours, suction filter the mixed solution of metal salt and silicon source, disperse the obtained filter residue powder in 50°C ethanol solution under constant temperature stirring for 30 hours for dispersion treatment, and then suction filter; the above dispersion treatment After the filter residue powder was calcined at 800° C. for 0.5 h, a powdery substance was obtained, which...

Embodiment 2

[0044] Dissolve 0.42g of manganese nitrate tetrahydrate, 0.19g of copper sulfate pentahydrate and 0.03g of cerium nitrate hexahydrate in 200mL of pure water, and fully stir to form a clear mixed salt solution; 28.42g of sodium silicate nonahydrate and 0.20g of eighteen Alkyl trimethyl ammonium bromide is mixed and dissolved in 1000 mL of pure water to obtain a silicon source solution, and 10 mL of 1mol / L sodium hydroxide is added to adjust the pH of the solution to 8.0, and heated to 30 ° C; quickly add the above-mentioned silicon source solution to the above-mentioned silicon source solution. Mix the salt solution and stir vigorously; after the reaction for 0.5h, suction filter the mixed solution of metal salt and silicon source, disperse the obtained filter residue powder in 70°C ethanol solution and stir at constant temperature for 5h for dispersion treatment, and then suction filter; The treated filter residue powder was calcined at 300 °C for 5 hours to obtain a powdery su...

Embodiment 3

[0047] Dissolve 0.87g of manganese nitrate tetrahydrate, 0.20g of copper sulfate pentahydrate and 0.33g of cerium nitrate hexahydrate in 200mL of pure water, and fully stir to form a clear mixed salt solution; 28.42g of sodium silicate nonahydrate and 10.00g of eighteen Alkyl trimethyl ammonium bromide was mixed and dissolved in 1000 mL of pure water to obtain a silicon source solution, and 23 mL of 1mol / L sodium hydroxide was added to adjust the pH of the solution to 11.0, and heated to 30 ° C; quickly add the above-mentioned silicon source solution to the above-mentioned solution. Mix the salt solution and stir vigorously; after the reaction for 5 hours, suction filter the mixed solution of metal salt and silicon source, disperse the obtained filter residue powder in an ethanol solution at 30 °C, stir at constant temperature for 20 hours, and then suction filter; The filter residue powder was calcined at 400 °C for 3 hours to obtain a powdery substance, which was a nanocompos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com