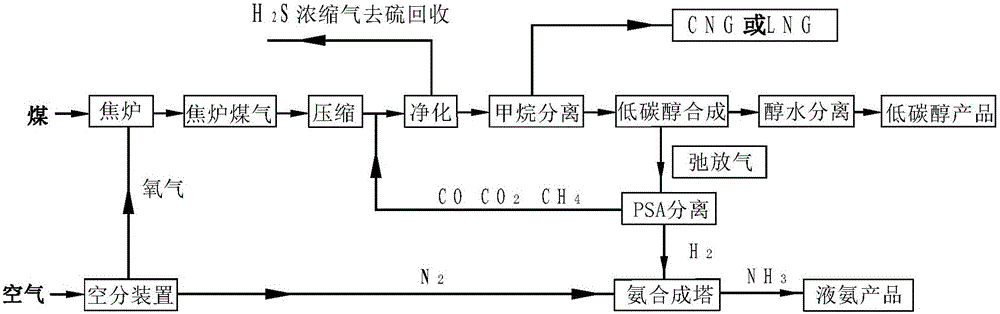

Method for synthesizing lower alcohol by coke oven gas and secondarily producing natural gas and liquid ammonia

A technology for coke oven gas and low-carbon alcohol, which is applied in chemical instruments and methods, preparation/separation of ammonia, preparation of organic compounds, etc., can solve problems such as energy waste and environmental pollution, reduce production costs, and improve enterprise economy. benefits, social and environmental benefits, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The coking coal and the oxygen produced by the air separation unit are sent to the coke oven to obtain coke products and crude coke oven gas; the crude coke oven gas is compressed and enters the coke together with the purge gas separated by PSA (pressure swing adsorption). Furnace gas low-temperature methanol washing and purification system, desulfurization treatment is carried out under the conditions of temperature -48°C and pressure 4.2MPa to obtain H 2 Purified coke oven gas with S2 S condensed gas desulfurization and recovery; the purified coke oven gas adopts the cryogenic separation technology of American Chemtex and Berkeley Weizi Company, and separates CH at a temperature of -159°C and a pressure of 4.0MPa. 4 , separated CH 4 Made into LNG (liquefied natural gas) products;

[0030] Separation of CH 4 The final coke oven gas enters two low-carbon alcohol fixed-bed reactors in series, and the fixed-bed reactors are filled with MoS from DOW Chemical Company of t...

Embodiment 2

[0034] The coking coal and the oxygen produced by the air separation unit are sent to the coke oven to obtain coke products and crude coke oven gas; the crude coke oven gas is compressed and enters the coke together with the purge gas separated by PSA (pressure swing adsorption). Furnace gas low-temperature methanol washing and purification system, desulfurization treatment is carried out under the conditions of temperature -50°C and pressure 4.5MPa to obtain H 2 Purified coke oven gas with S2S condensed gas desulfurization recovery; the purified coke oven gas is subjected to pressure swing adsorption to separate methane, and activated carbon is used as the adsorbent to separate CH at a temperature of 15°C, an adsorption pressure of 4.8 MPa, and a desorption pressure of 0.6 MPa. 4 , separated CH 4 Made into CNG (compressed natural gas) products;

[0035] Separation of CH 4 The final coke oven gas enters three low-carbon alcohol fixed-bed reactors connected in series. The fix...

Embodiment 3

[0039] The coking coal and the oxygen produced by the air separation unit are sent to the coke oven to obtain coke products and crude coke oven gas; the crude coke oven gas is compressed and enters the coke together with the purge gas separated by PSA (pressure swing adsorption). Furnace gas tannin extract method purification system for desulfurization treatment to obtain H 2 Purified coke oven gas with S2 S condensed gas desulfurization and recovery; the purified coke oven gas adopts the cryogenic separation technology of American Chemtex and Bockley Weizi Company, and separates CH at a temperature of -165°C and a pressure of 5.0MPa. 4 , separated CH 4 Made into LNG (liquefied natural gas) products;

[0040] Separation of CH 4 The final coke oven gas enters two low-carbon alcohol fixed-bed reactors connected in series. The fixed-bed reactors are filled with Zn-Cr catalysts from the Shanxi Institute of Coal Chemistry, Chinese Academy of Sciences. 2 / CO molar ratio 2.5, spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com