Preparation method for nanometer flaky ferrierite molecular sieve

A ferrierite and nano-sheet technology, which is applied in the field of zeolite molecular sieve synthesis, can solve the problems of large amount of template agent, narrow silicon-aluminum ratio range, limited reduction of molecular sieve particle size, etc., and achieves wide synthesis phase area and simple synthesis method. , the prospect of industrial application has a significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dissolve 4.45 grams of aluminum sulfate octadecahydrate and 1.18 grams of concentrated sulfuric acid in 70 grams of water, slowly add the obtained solution dropwise to 53.4 grams of water glass (silica content 22.5wt%; sodium oxide content 6.7wt%), and then add 5.96 grams of piperidine are structure-directing agents and 3.644 grams of cetyltrimethylammonium bromide (CTABr), SiO in the synthesis system 2 / Al 2 o 3 The molar ratio is 30; Na 2 O / SiO 2 The molar ratio is 0.13; H 2 O / SiO 2 The molar ratio is 30; piperidine / SiO 2 The molar ratio is 0.35; CTABr / SiO 2 The molar ratio was 0.05, and the synthetic system was stirred at room temperature for 2 hours, then at 150 o The crystallization reaction was carried out at a temperature of C for 5 days, and after the reaction was completed, the product was filtered and dried to obtain a nano-flaky ferrierite molecular sieve.

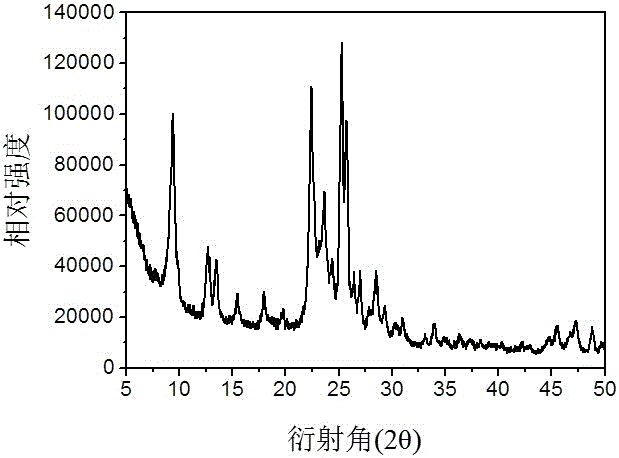

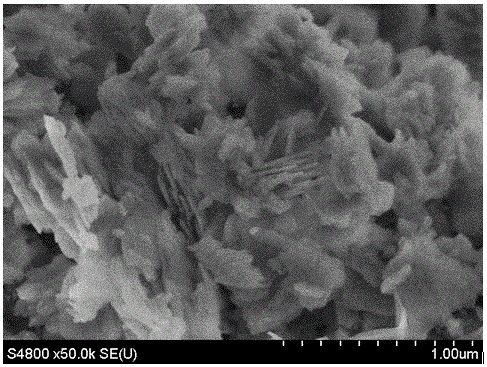

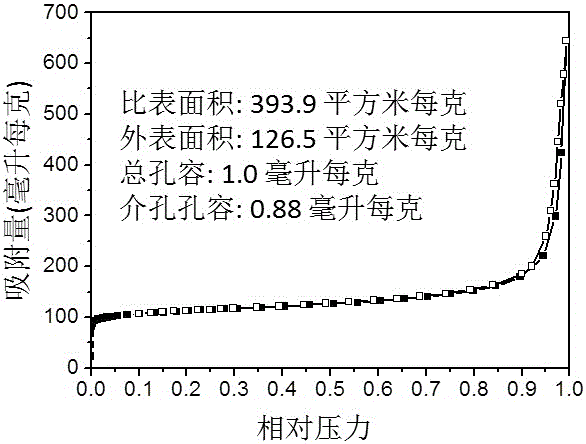

[0020] See attached figure 1 , The product obtained in Example 1 is measured by XRD and its c...

Embodiment 2

[0024] 0.53 gram of sodium hydroxide and 1.90 gram of sodium metaaluminate (aluminum oxide mass content 53.6%, sodium oxide mass content 43.8%) were dissolved in 36 grams of water, then 4.65 gram of hexamethylenediamine was added as structure directing agent, 12.72 gram of Qingdao silica gel ( Solid content 94.6%) and 7.29 grams of cetyltrimethylammonium bromide (CTABr), SiO in the synthesis system 2 / Al 2 o 3 The molar ratio is 20; Na 2 O / SiO 2 The molar ratio is 0.10; H 2 O / SiO 2 The molar ratio is 10; Hexamethylenediamine / SiO 2 The molar ratio is 0.2; CTABr / SiO 2 The molar ratio was 0.1, and the synthesis system was stirred at room temperature for 3 hours, then at 150 o The crystallization reaction was carried out at a temperature of C for 5 days, and after the reaction was completed, the product was filtered and dried to obtain a nano-flaky ferrierite molecular sieve.

[0025]The crystal phase of the obtained product was measured by XRD as FER topological structure...

Embodiment 3

[0026] 1.06 grams of sodium hydroxide and 0.95 grams of sodium metaaluminate (alumina mass content 53.6%, sodium oxide mass content 43.8%) were dissolved in 12 grams of water, and the solution obtained was slowly added dropwise to 53.4 grams of water glass (silicon oxide content 22.5wt%; sodium oxide content 6.7wt%), then add 0.032 grams of pyridine as a structure-directing agent, 20 grams of silica sol (silicon oxide 30%) as a silicon source and 0.073 grams of cetyltrimethylammonium bromide ( CTABr); SiO in the synthesis system 2 / Al 2 o 3 The molar ratio is 40; Na 2 O / SiO 2 The molar ratio is 0.10; H 2 O / SiO 2 The molar ratio is 15; pyridine / SiO 2 The molar ratio is 0.02; CTABr / SiO 2 The molar ratio was 0.01, and the synthesis system was stirred at room temperature for 3 hours, then at 160 o The crystallization reaction was carried out at a temperature of C for 2 days, and after the reaction was completed, the product was filtered and dried to obtain a nano-flaky fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com