Quaternary ammonium salt antibacterial agent and structural type antibacterial resin

A quaternary ammonium salt and antibacterial agent technology, applied in the field of antibacterial coatings, can solve the problems of uneven dispersion, attenuation of antibacterial properties of antibacterial coatings, loss of antibacterial properties, etc., to achieve more stable antibacterial properties, stable antibacterial properties, and simple and easy control of the preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 quaternary ammonium salt antibacterial agent

[0028] A kind of quaternary ammonium antibacterial agent of the present embodiment, its preparation method is as follows:

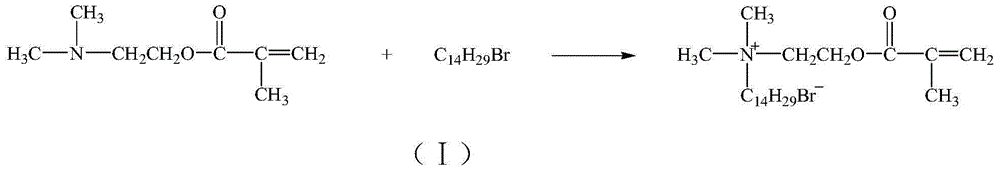

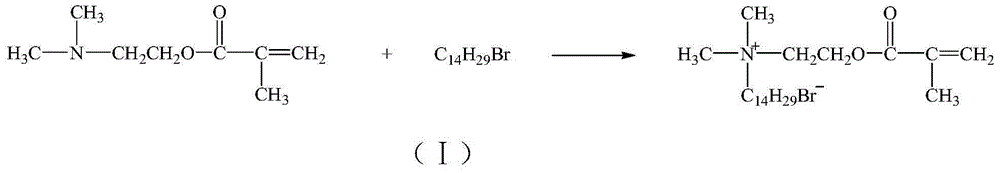

[0029] According to the ratio of dimethylaminoethyl methacrylate (DMAEMA):bromotetradecane molar ratio=1:1.1, weigh dimethylaminoethyl methacrylate (DMAEMA) and bromotetradecane In a three-necked flask equipped with a mechanical stirrer, a reflux condenser, and a thermometer, heat the reaction under reflux in an oil bath, the reaction temperature is 110°C, and prepare tetradecyl ethyl methacrylate dimethyl bromide after 110 minutes of reaction Ammonium, the tetradecyl ethyl methacrylate dimethyl ammonium bromide is the quaternary ammonium salt antibacterial agent of the present embodiment.

[0030] The conversion rate of the quaternary ammonium salt antibacterial agent in this embodiment is 97%, and its reaction equation is shown in formula (I).

[0031]

Embodiment 2

[0032] The antibacterial performance experiment of embodiment 2 quaternary ammonium salt antibacterial agent

[0033] In this example, the quaternary ammonium salt antibacterial agent prepared in Example 1 was tested for its antibacterial properties.

[0034] Experimental method: According to the relevant guidelines of the 2002 version of the "Disinfection Technical Specifications" of the Ministry of Health, the minimum inhibitory concentration (MIC) of quaternary ammonium antibacterial agents can be tested according to the "Agar Dilution Method" in the specifications. Mix a certain gradient concentration of quaternary ammonium salt antibacterial agent solution with a certain concentration of bacterial suspension, dissolve evenly in the agar medium, place it in a constant temperature incubator for 24 hours, and observe the growth of the bacteria to determine the antibacterial effect of the quaternary ammonium salt. The lowest concentration at which the agent inhibits the growt...

Embodiment 3

[0053] Embodiment 3 structural type antibacterial resin

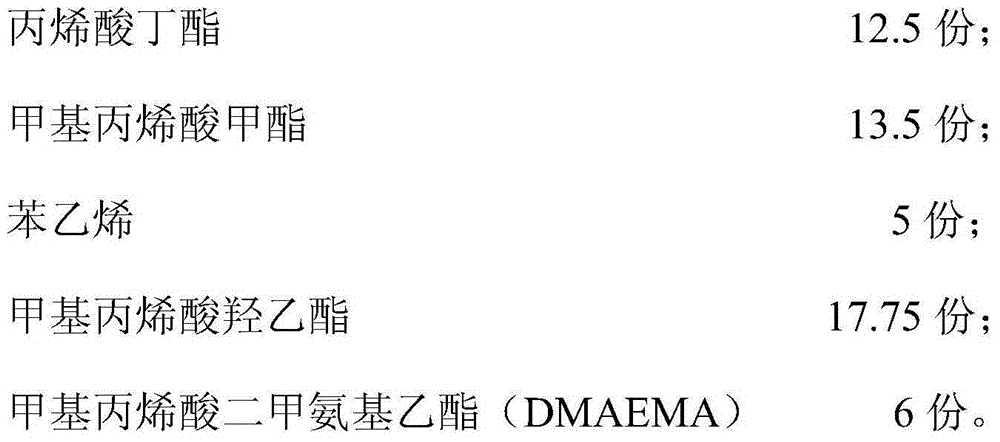

[0054] This embodiment prepares 6 kinds of structural type antibacterial resins altogether, these 6 kinds of structural type antibacterial resins all adopt the quaternary ammonium salt antibacterial agent prepared in embodiment 1, and these 6 kinds of structural type antibacterial resins are different except the addition amount of quaternary ammonium salt antibacterial agent Except, all the other preparation methods are the same, and the specific preparation method is as follows:

[0055] In a 250mL three-necked flask, add 32.85g of solvent propylene glycol methyl ether acetate and stir and heat up to 90°C, dropwise add the mixture of monomer, quaternary ammonium salt antibacterial agent and initiator azobisisobutyronitrile, and the dropping process controls the temperature to 88°C~93°C, the dropping time is 1.5~2.0 hours, add the initiator azobisisobutyronitrile after the dropwise addition, then control the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com