Self-cleaning nitrogen-doped titanium oxide film as well as preparation method and applications thereof

A titanium dioxide, self-cleaning technology, applied in the direction of protection devices against harmful chemicals, etc., can solve the problems of high cost, insignificant improvement, improved photocatalytic efficiency, etc., to prevent pollution, improve catalytic efficiency, and good film-forming properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

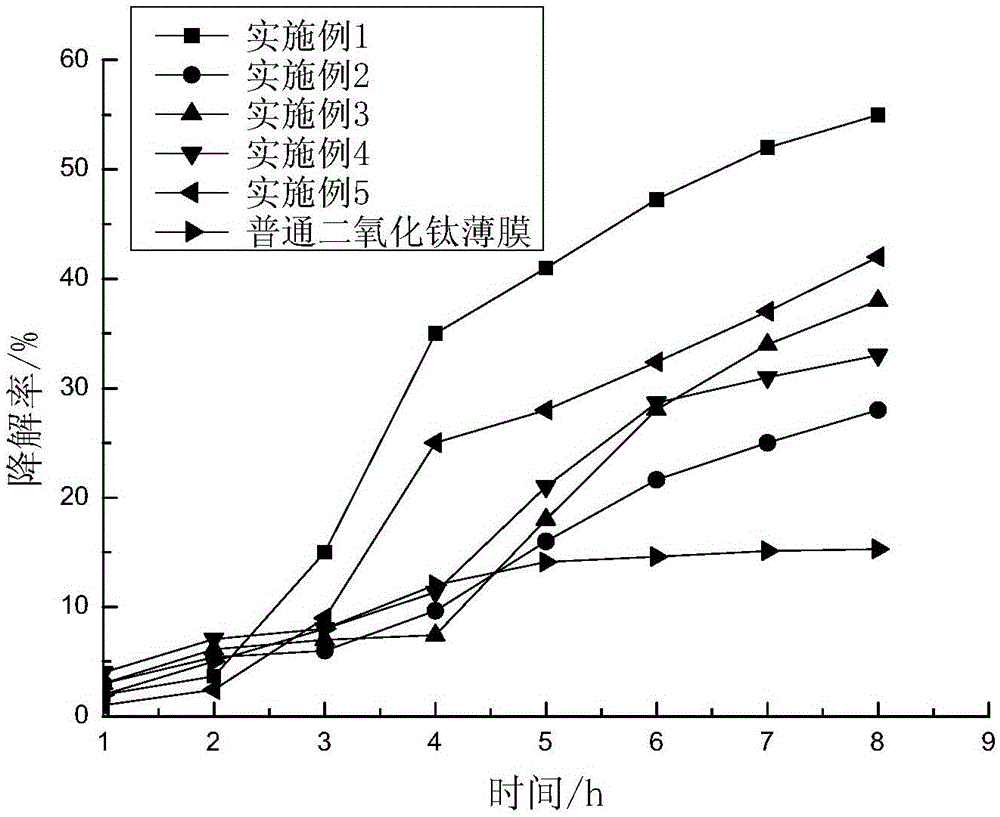

Examples

Embodiment 1

[0029] 1) Mix butyl titanate and absolute ethanol uniformly at a volume ratio of 1:2, then add acetylacetone under stirring, stir for 15 minutes, and mix uniformly to obtain a light yellow solution A; the volume fraction of acetylacetone is 3 %.

[0030] 2) Mix ionized water, hydrochloric acid, and absolute ethanol uniformly according to a volume ratio of 1:0.3:10, add polyvinylpyrrolidone, and stir for 10 minutes to obtain a transparent solution B; wherein polyvinylpyrrolidone accounts for 2% of the total mass of the solution, wherein The mass fraction of hydrochloric acid is 36%.

[0031] 3) Drop the transparent light yellow solution A into the transparent solution B drop by drop, and the volume ratio of solution A to solution B is 1:1, after stirring at room temperature for 2 hours, a uniform sol C is formed; the homogeneous sol is aged at room temperature for 12 hours to obtain Sol required for coating.

[0032] 4) Put the ceramic substrate to be coated into a mixed solu...

Embodiment 2

[0046] 1) Mix butyl titanate and absolute ethanol uniformly at a volume ratio of 1:5, then add acetylacetone under stirring, stir for 15 minutes, and mix uniformly to obtain a light yellow solution A; the volume fraction of acetylacetone is 2 %.

[0047] 2) Mix ionized water, hydrochloric acid, and absolute ethanol uniformly according to a volume ratio of 1:0.2:5, add polyvinylpyrrolidone, and stir for 15 minutes to obtain a transparent solution B; wherein polyvinylpyrrolidone accounts for 5% of the total mass of the solution, wherein The mass fraction of hydrochloric acid is 36%.

[0048] 3) Drop the transparent light yellow solution A into the transparent solution B drop by drop, and the volume ratio of solution A to solution B is 1:2, after stirring at room temperature for 3 hours, a uniform sol C is formed; the homogeneous sol is aged at room temperature for 24 hours to obtain Sol required for coating.

[0049] 4) Put the substrate to be coated into a mixed solution of d...

Embodiment 3

[0053] 1) Mix butyl titanate and absolute ethanol uniformly at a volume ratio of 1:3, then add acetylacetone under stirring, stir for 15 minutes, and mix uniformly to obtain a light yellow solution A; the volume fraction of acetylacetone is 2% .

[0054] 2) Mix ionized water, hydrochloric acid, and absolute ethanol uniformly according to the volume ratio of 1:0.5:15, add polyvinylpyrrolidone, and stir for 30 minutes to obtain a transparent solution B; wherein polyvinylpyrrolidone accounts for 1% of the total mass of the solution, wherein The mass fraction of hydrochloric acid is 36%.

[0055] 3) Drop the transparent light yellow solution A into the transparent solution B drop by drop, and the volume ratio of solution A to solution B is 1:0.5, and stir at room temperature for 3 hours to form a uniform sol C; the homogeneous sol is aged at room temperature for 36 hours to obtain Sol required for coating.

[0056] 4) Put the ceramic substrate to be coated into a mixed solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com