Anti-continuous-cropping microbial fertilizer and preparation method therefor

A technology of microbial fertilizer and compound microbial bacteria, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of soil aggregate structure reducing water and fertilizer retention capacity, no major breakthrough progress, and destruction of micro-ecological balance, etc. Promote photosynthesis, strengthen leaf protective film, and promote the effect of crop root growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

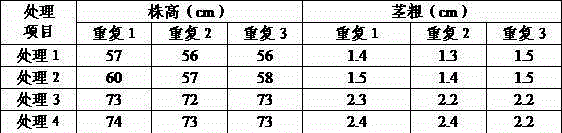

Image

Examples

Embodiment 1

[0017] The anti-cropping microbial fertilizer of the present embodiment and its preparation process are,

[0018] (1) Production of anti-heavy cropping compound microbial bacterial liquid: bean cake powder 80kg / ton, corn starch 48kg / ton, bran 100kg / ton, fish meal 50kg / ton. Proportionally add to the fermenter and inject the corresponding water, adjust the pH value to 7.2, steam sterilization (temperature: 121°C, pressure 0.12Mpa) for 30 minutes, the temperature drops to 35°C, add the compound spore species (Bacillus subtilis: Paenibacillus jelly-like: Bacillus licheniformis (mass ratio = 1:1:1), fermented for 16 hours at a constant aeration and temperature, and the sporulation rate of Bacillus reached 85% through microscope inspection, and the anti-replantation Composite microbial fluid.

[0019] (2) Production of anti-cropping compound microbial agent: mix and absorb the anti-cropping compound microbial liquid and humic acid in a ratio of 1:3, so that the anti-cropping compou...

Embodiment 2

[0022] The anti-cropping microbial fertilizer of the present embodiment and its preparation process are,

[0023] (1) Production of anti-heavy cropping compound microbial bacterial liquid: bean cake powder 160kg / ton, corn starch 360kg / ton, bran 280kg / ton, fish meal 40kg / ton. Add it into the fermenter in proportion and inject corresponding water, adjust the pH value to 7.8, steam sterilize (temperature: 121°C, pressure 0.12Mpa) for 20 minutes, and drop the temperature to 37°C, add the compound spore species (Bacillus subtilis: The mass ratio of Paenibacillus jelly-like: Bacillus licheniformis = 1:1:1), fermented at constant ventilation and temperature for 20 hours, and the sporulation rate of Bacillus reached 90% after microscopic examination, and the anti-replantation Composite microbial fluid.

[0024] (2) Production of anti-cropping compound microbial agent: mix and absorb the anti-cropping compound microbial liquid and humic acid at a ratio of 1:5, so that the anti-croppin...

Embodiment 3

[0027] The anti-cropping microbial fertilizer of the present embodiment and its preparation process are,

[0028] (1) Production of anti-stubble compound microbial bacterial liquid: 120kg / ton of bean cake powder, 200kg / ton of corn starch, 190kg / ton of bran, and 80kg / ton of fish meal. Add it into the fermenter in proportion and inject corresponding water, adjust the pH value to 7.4, steam sterilize (temperature: 121°C, pressure 0.12Mpa) for 25 minutes, then drop the temperature to 35°C, add compound spore species (Bacillus subtilis: The mass ratio of Paenibacillus jelly-like: Bacillus licheniformis = 1:1:1), fermented at constant ventilation and temperature for 18 hours, and the sporulation rate of Bacillus reached 88% after microscopic examination, and the anti-replantation Composite microbial fluid.

[0029] (2) Production of anti-cropping compound microbial agent: mix and absorb the anti-cropping compound microbial liquid and humic acid in a ratio of 1:4, so that the anti-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com