Method for synthetizing Au/ZnO bar-shaped heterojunction photocatalyst

A photocatalyst, heterojunction technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high semiconductor carrier recombination rate, size, Uniformity is difficult to control, low solar energy utilization efficiency, etc., to achieve good application prospects, stable and efficient visible light catalytic performance, and improved catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

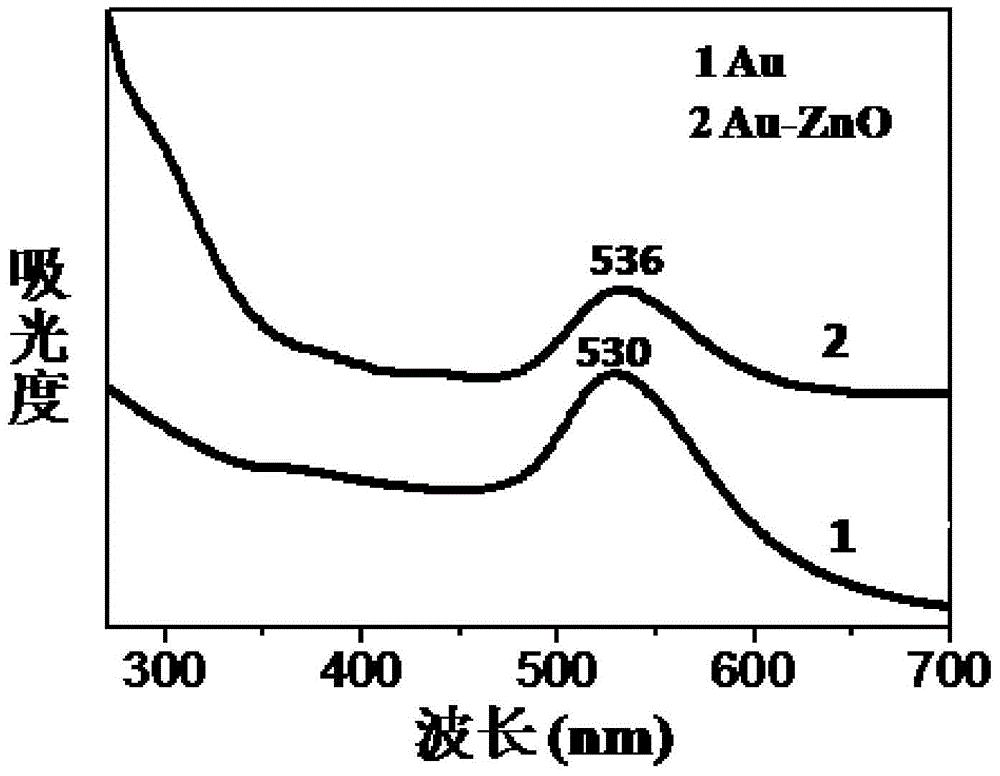

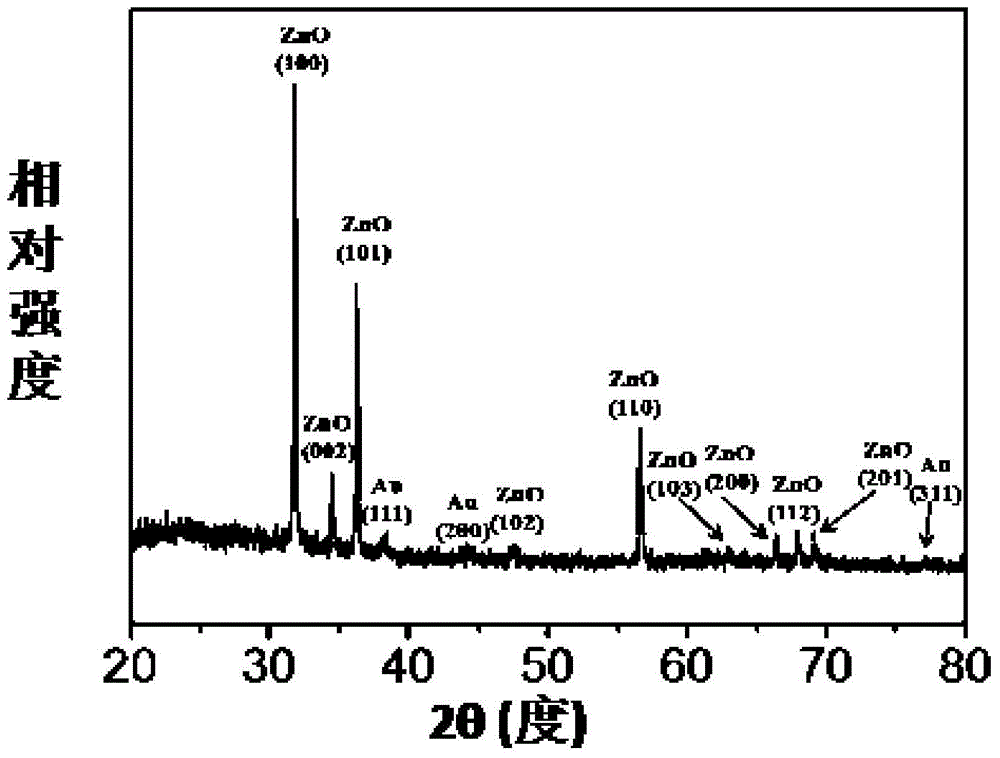

[0018] Au nanoparticle colloid solution (the diameter of Au nanoparticle is 40nm) was prepared by reducing chloroauric acid with sodium citrate. After centrifuging 30mL of the Au nanoparticle colloidal solution at a speed of 6000rpm for 8 minutes, the lower layer of concentrated solution (0.4mL in volume) was taken, and then 240mL of polyvinylpyrrolidone aqueous solution with a concentration of 20mg / mL and nitric acid with a concentration of 50mM were added successively. 5 mL of zinc aqueous solution, 5 mL of hexamethylenetetramine aqueous solution with a concentration of 50 mM, and then heated at 95 ° C for 2.5 hours to obtain a pink Au / ZnO rod-shaped heterojunction photocatalyst with a product quality of 20 mg.

[0019] Embodiment 1 performance test

[0020] Get 4mg of the Au / ZnO rod-shaped heterojunction photocatalyst prepared by the present invention and add it into 4mL of rhodamine B aqueous solution (5ppm), stir in the dark for 30min so that the nanoparticles are evenly ...

Embodiment 2

[0026] Au nanoparticle colloid solution (the diameter of Au nanoparticle is 40nm) was prepared by reducing chloroauric acid with sodium citrate. After centrifuging 30mL of the Au nanoparticle colloidal solution at a speed of 6000rpm for 8 minutes, take the lower layer of concentrated solution (volume is 0.4mL), and then add 240mL of polyvinylpyrrolidone aqueous solution with a concentration of 10mg / mL, and nitric acid with a concentration of 50mM 5 mL of zinc aqueous solution and 5 mL of hexamethylenetetramine aqueous solution with a concentration of 50 mM were then heated at 95°C for 2.5 hours to obtain a pink Au / ZnO rod-shaped heterojunction photocatalyst with a product quality of 19 mg.

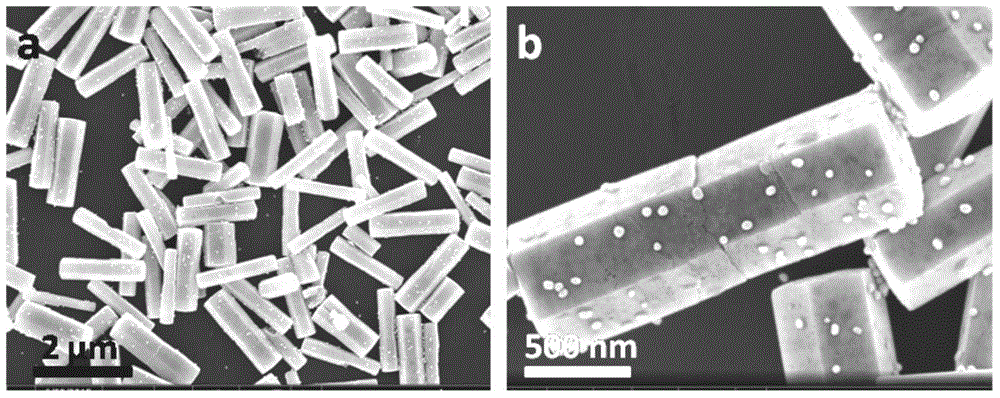

[0027] attached Figure 5is the transmission electron micrograph of the obtained Au / ZnO rod-shaped heterojunction photocatalyst. As shown in the figure, a uniform rod-like structure is displayed in a large range, with a rod length of 1900nm and a width of 500nm; the Au nanoparticles are u...

Embodiment 3

[0029] The Au nanoparticle colloid solution (the diameter of the Au nanoparticle is 15 nm) was prepared by reducing chloroauric acid with sodium citrate. After centrifuging 60mL of the Au nanoparticle colloidal solution at a speed of 12000rpm for 15 minutes, the concentrated solution of the lower layer (volume is 0.8mL) was taken, and then 240mL of polyvinylpyrrolidone aqueous solution with a concentration of 20mg / mL and nitric acid with a concentration of 50mM were added successively. 5 mL of zinc aqueous solution, 5 mL of hexamethylenetetramine aqueous solution with a concentration of 50 mM, and then heated at 95 ° C for 2.5 hours to obtain a pink Au / ZnO rod-shaped heterojunction photocatalyst with a product quality of 20 mg.

[0030] The prepared Au / ZnO rod-shaped heterojunction photocatalyst has a length of 1300nm and a width of 500nm; the ZnO rod has a wurtzite structure, and Au nanoparticles are uniformly decorated on the surface of the ZnO rod, and the diameter of the Au...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com