Catalyst for reforming methane and carbon dioxide to prepare synthesis gas, and preparation method for catalyst

A carbon dioxide and catalyst technology, applied in the field of catalyst for methane carbon dioxide reforming to syngas and its preparation, can solve the problems of low space velocity, high test conditions, clogging of the reactor, etc., and achieves high catalytic oxidation efficiency, good stability, Effects of high oxygen storage capacity and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

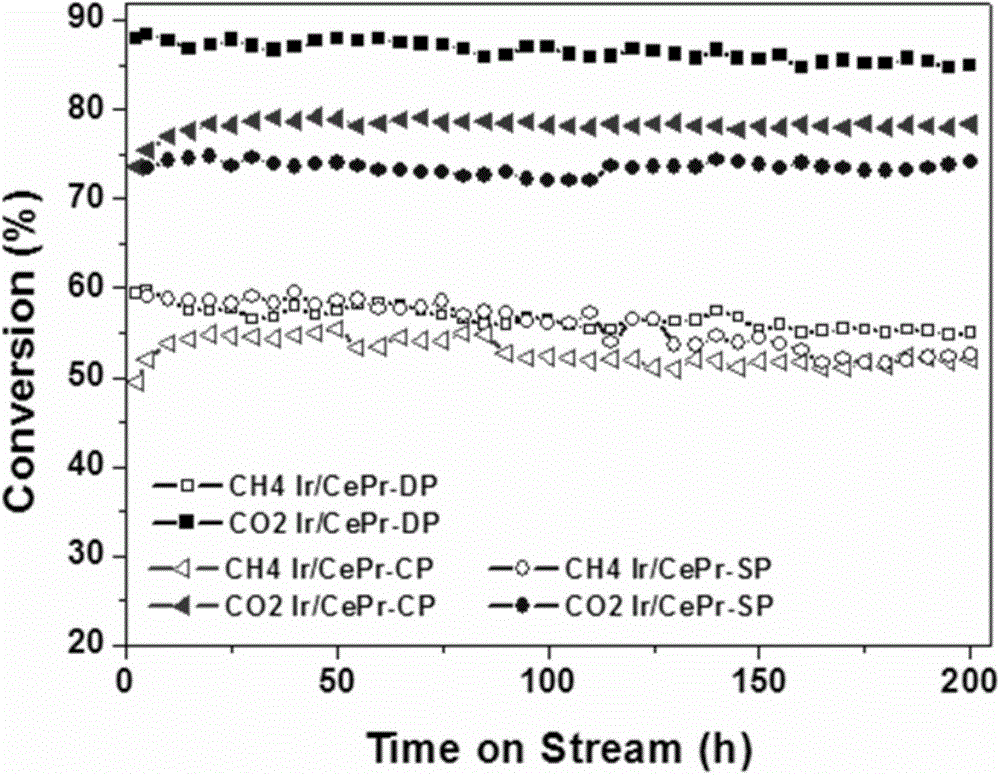

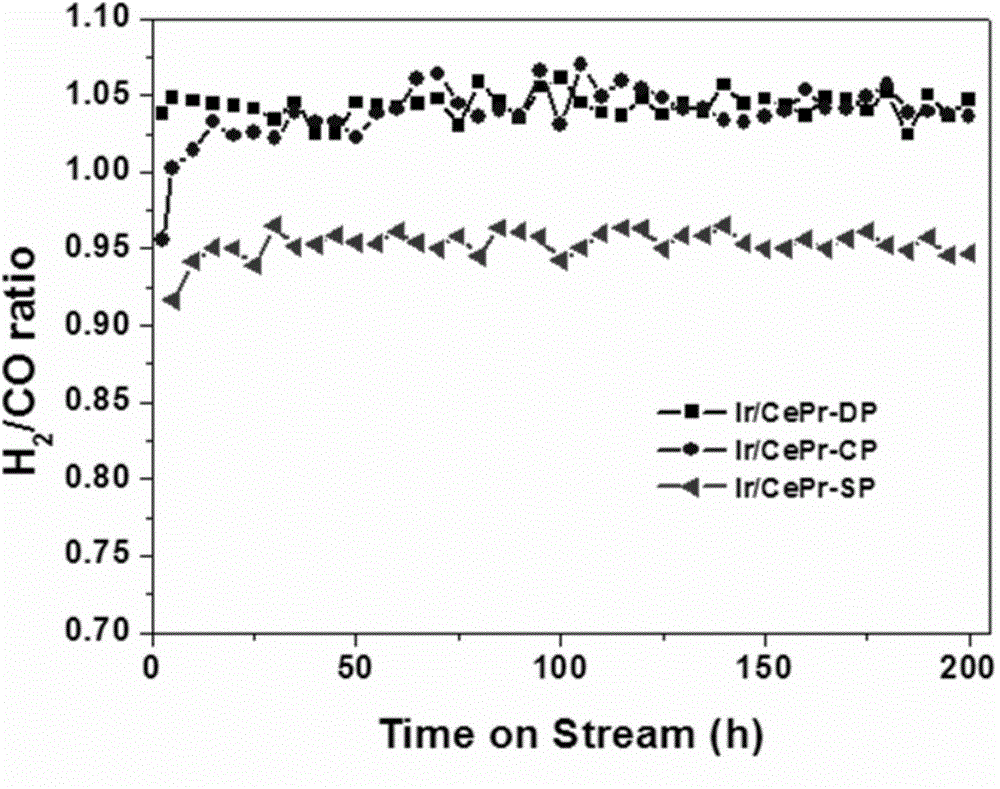

[0042] This embodiment is a catalyst for reforming methane and carbon dioxide to produce synthesis gas. The composition and mass percentage of the catalyst are: metal iridium 2%, cerium oxide-based solid solution 98%. The preparation method is as follows:

[0043] (1) 2.42g of cerium nitrate and 0.27g of praseodymium nitrate are added to 500mL of distilled water for dissolving in 500mL of distilled water at a ratio of 9:1 by cerium to praseodymium nitrate to obtain a mixed solution;

[0044] (2) The mixed solution was heated and hydrolyzed at 90°C for 5h, filtered, washed and dried at 100°C, and then roasted at 400°C for 4 hours to obtain a ceria-praseodymia solid solution;

[0045] (3) Add cerium oxide-praseodymium oxide solid solution powder into distilled water, stir and disperse, and add chloroiridic acid solution containing 0.02g of iridium, then heat to 65-75°C, and slowly add 0.1mol / L sodium carbonate or Sodium bicarbonate solution to solution pH = 8-9, aging for 2-4 h...

Embodiment 2

[0050] This embodiment is a catalyst for reforming methane and carbon dioxide to produce synthesis gas. The composition and mass percentage of the catalyst are: metal iridium 2%, cerium oxide-based solid solution 98%. The preparation method is as follows:

[0051] (1) 2.42g of cerium nitrate and 0.25g of lanthanum nitrate are added to 500mL of distilled water for dissolving in 500mL of distilled water according to the molar ratio of cerium to lanthanum and 0.25g of lanthanum nitrate, then add 50g of urea to obtain a mixed solution;

[0052] (2) The mixed solution was heated and hydrolyzed at 90°C for 5 hours, filtered, washed and dried at 100°C, and then roasted at 400°C for 4 hours to obtain a cerium oxide-lanthanum oxide solid solution;

[0053] (3) Add cerium oxide-lanthanum oxide solid solution powder into distilled water, stir and disperse, and add chloroiridic acid solution containing 0.02g of iridium, then heat to 65-75°C, and slowly add 0.1mol / L sodium carbonate or So...

Embodiment 3

[0058] This embodiment is a catalyst for reforming methane and carbon dioxide to produce synthesis gas. The composition and mass percentage of the catalyst are: metal iridium 2%, cerium oxide-based solid solution 98%. The preparation method is as follows:

[0059] (1) 2.42g of cerium nitrate and 0.14g of zirconium oxynitrate are added to 500mL of distilled water for dissolving in 500mL of distilled water according to the molar ratio of cerium to zirconium of 9:1, and then 50g of urea is added to obtain a mixed solution;

[0060] (2) Heating and hydrolyzing the mixed solution at 90°C for 4 hours, filtering, washing and drying at 100°C, and then roasting at 400°C for 4 hours to obtain a ceria-zirconia solid solution;

[0061] (3) Add cerium oxide-zirconia solid solution powder into distilled water, stir and disperse, and add chloroiridic acid solution containing 0.02g of iridium, then heat to 65-75°C, and slowly add 0.1mol / L sodium carbonate or Sodium bicarbonate solution to so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com