While drilling processing method for oily drilling cuttings

A processing method and technology for drilling cuttings, which are applied in the petroleum industry, earth-moving drilling, wellbore/well components, etc., can solve the problems of recycling and resource utilization of unfavorable base oil substances, long microbial metabolism cycle, and high residual oil content. To achieve the effect of strong operability and practicability, improve oil washing effect, and improve treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below:

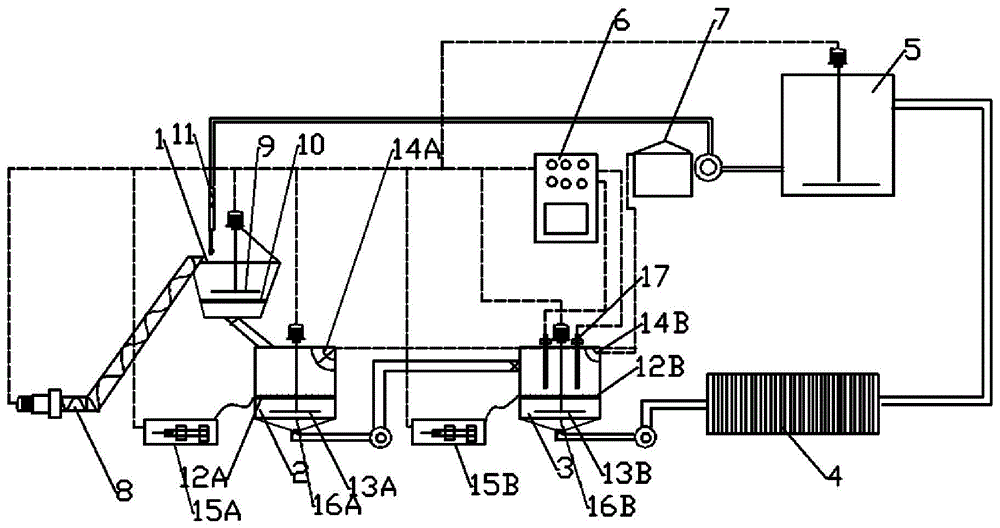

[0020] Such as figure 1 As shown, the oily drilling cuttings processing device of the present invention includes a feeding hopper 1, a fluidized pretreatment tank 2, a cleaning tank 3, a plate and frame filter press 4, a circulating water tank 5, a control cabinet 6, an oil recovery tank 7, and a screw conveyor 8; the screw conveyor 8 is installed obliquely, and its upper end outlet is placed on the feeding hopper 1, a high-pressure nozzle 11 is installed above the feeding hopper 1, a mechanical grill 10 is installed at the bottom of the feeding hopper 1, and a cutting mechanical agitator 9 is installed on the mechanical Above the grid 10, an outlet is provided at the bottom of the feeding hopper 1, and a downflow pipe is installed between the outlet and the fluidized pretreatment tank 2; In the middle, the microporous aeration head 12A is installed at a position 200 mm away from the wall and 1 / 3 of the height fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com